Silicon-based lithium niobate high-speed light modulator and preparation method thereof

A silicon-based lithium niobate, optical modulator technology, applied in the field of optical communication, can solve the theoretical upper limit of nonlinear electro-optical effect of high cost and temperature sensitive silicon optical modulators, difficult to achieve heterogeneous integration or monolithic integration, devices Drive voltage increase and other issues, to achieve high stability, high bandwidth, reduce the effect of drive voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

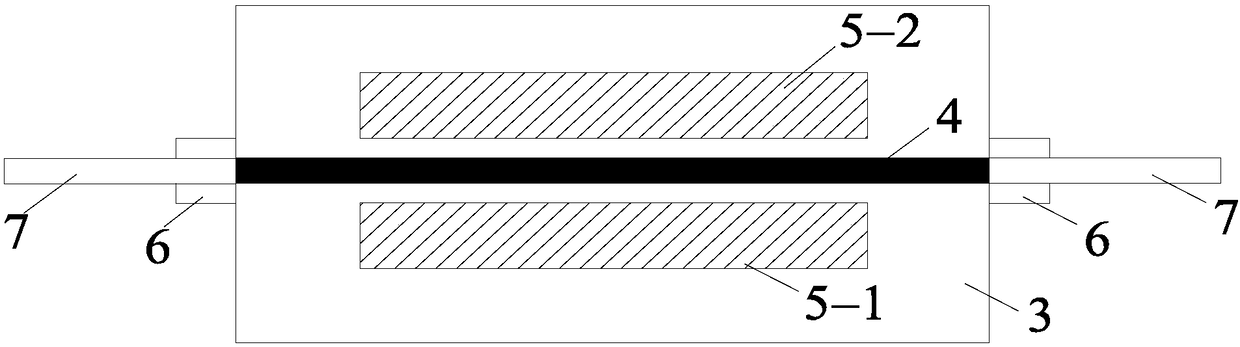

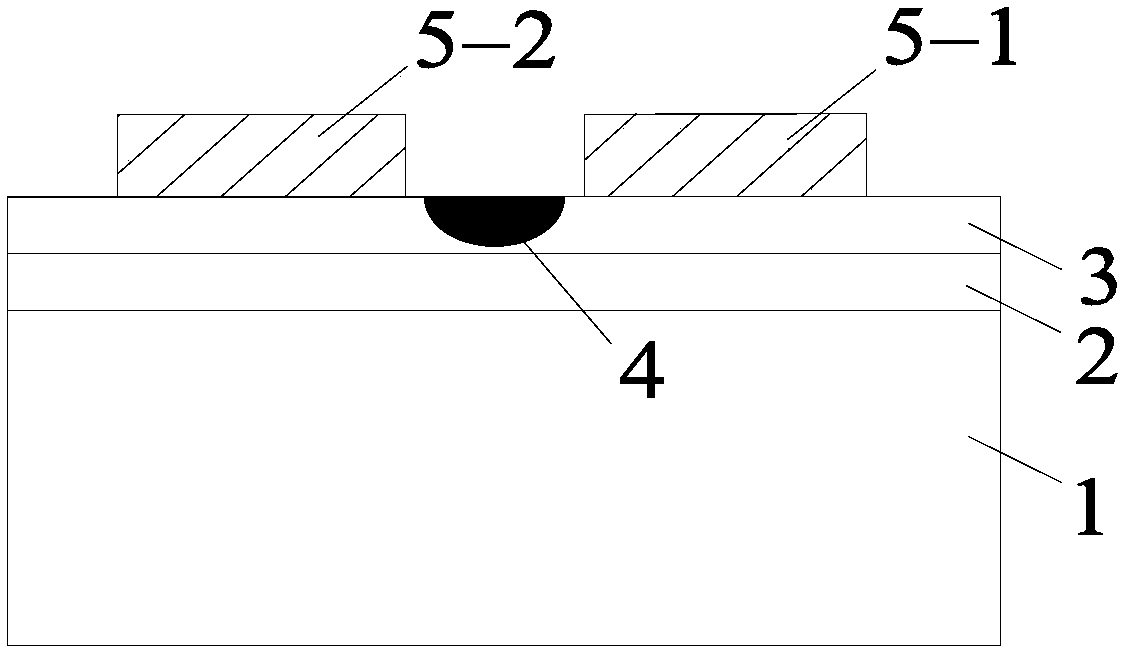

[0058] Such as figure 1 with figure 2 As shown, the silicon-based lithium niobate high-speed light modulator in this embodiment includes: a silicon substrate wafer 1, a silicon dioxide under-cladding layer 2, a lithium niobate film 3, an optical waveguide 4, a metal electrode 5, The signal electrode 5-1, the ground electrode 5-2, the silicon V-groove 6, and the coupling optical fiber 7. The silicon-based lithium niobate high-speed optical modulator in this embodiment is a phase modulator, figure 1 Shown is the structure diagram of a silicon-based lithium niobate high-speed optical modulator, figure 2 Shown is a schematic cross-sectional view of the chip of a silicon-based lithium niobate high-speed light modulator.

[0059] The silicon base wafer 1 uses a single crystal silicon wafer with a [100] crystal orientation and low resistivity, with a thickness ranging from 0.1 mm to 2 mm. The crystal orientation of the silicon substrate wafer 1 is kept consistent with the crystal orien...

Embodiment 2

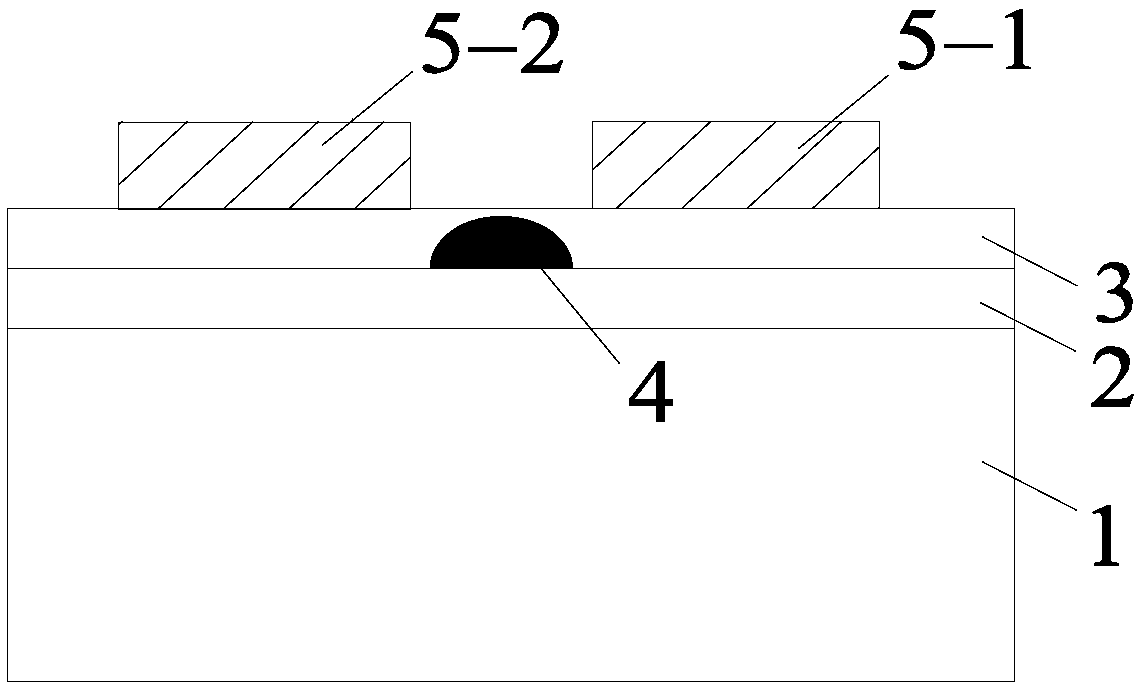

[0078] Such as figure 1 with image 3 As shown, the difference between this embodiment and the silicon-based lithium niobate high-speed optical modulator described in Embodiment 1 is that the optical waveguide 4 used in this embodiment is a titanium diffused optical waveguide. The technical solution of this embodiment is basically the same as that of embodiment 1, except that the optical waveguide 4 in embodiment 1 is changed from annealed proton exchange optical waveguide to a titanium diffused optical waveguide. The detailed technology will not be described here. Program.

[0079] In order to prepare the above-mentioned silicon-based lithium niobate high-speed optical modulator, this embodiment provides a method for preparing a silicon-based lithium niobate high-speed optical modulator including the following steps:

[0080] (1) On the upper surface of the silicon base wafer 1, a thermal oxidation process or any coating technology such as ion sputtering technology, magnetron sput...

Embodiment 3

[0090] Such as Figure 4 with Figure 5 As shown, the main difference between this embodiment and the silicon-based lithium niobate high-speed light modulator described in Embodiment 1 is that this embodiment is an intensity modulator. The specific differences between this embodiment and Embodiment 1 are:

[0091] First, the optical waveguide 4 adopts an MZ-type optical waveguide, which is composed of an input waveguide 4-1, a Y branch structure waveguide 4-2, a double-arm waveguide 4-3, and an output waveguide 4-4. The optical waveguide 4 is made of lithium niobate film Among them, the waveguide width is 1 μm to 10 μm, and the waveguide depth is 1 μm to 10 μm;

[0092] Second, the metal electrode 5 adopts a traveling wave electrode structure, which is composed of a signal electrode 5-1 and two ground electrodes 5-2, and is placed on the left, middle, and right sides of the dual-arm waveguide 4-3. The metal electrode 5 is fabricated on the upper surface of the lithium niobate film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com