Fabrication method of gan-based hemt devices

A device and wafer technology, applied in the semiconductor field, can solve the problems of poor device performance and high device fabrication cost, and achieve the effects of improving performance, expanding application scope and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

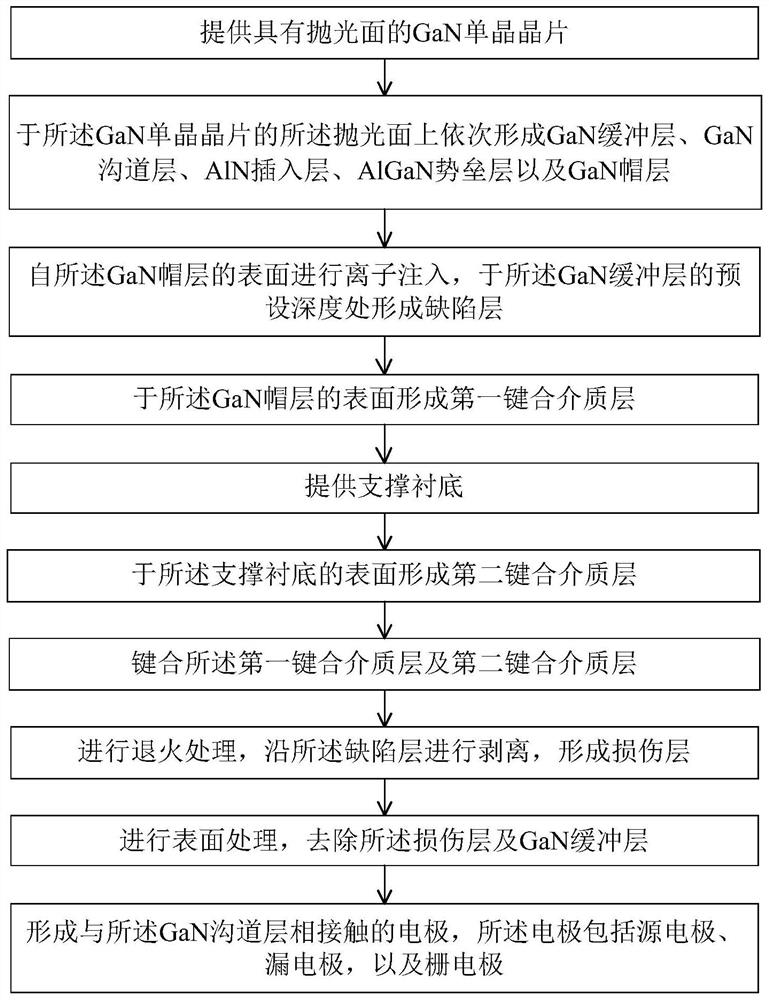

[0063] refer to figure 1 , the present invention provides a method for preparing a GaN-based HEMT device, which can transfer a high-quality AlGaN / GaN structure homoepitaxially on a self-supporting GaN single crystal substrate to a supporting substrate, and remove the residual layer on the surface after simple treatment. High-performance GaN-based HEMT devices can be obtained by growing source, drain, and gate electrodes; the self-supporting GaN single crystal substrate has no loss and can be recycled, thereby greatly reducing costs; according to the material characteristics of different supporting substrates, GaN can be realized The heterogeneous integration of the GaN-based HEMT device and the supporting substrate takes advantage of the different advantages of the GaN-based HEMT device to improve the performance of the GaN-based HEMT device, so that the GaN-based HEMT device can work stably for a long time under high frequency and high power conditions; further It can be appl...

Embodiment 1

[0095] like figure 2 As shown, a GaN single crystal wafer 100 with a diameter of 2 inches, a thickness of 350 μm, and a (0001) crystal orientation Ga surface polishing is firstly provided.

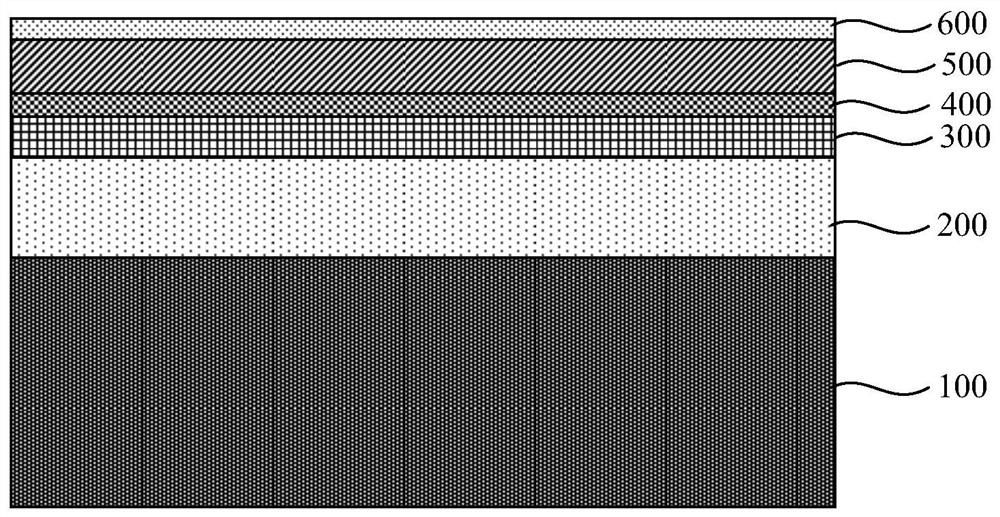

[0096] like image 3 As shown, on the polished surface 100a of the GaN single crystal wafer 100, a 2 μm thick GaN buffer layer 200, a 100 nm thick GaN channel layer 300, and a 1 nm thick AlN insertion Layer 400, 25nm thick Al X Ga 1-X N barrier layer 500, where x=0.25, 2nm thick GaN cap layer 600; constitute the first composite structure.

[0097] like Figure 4 , performing H ion implantation on the first composite structure from the direction of the GaN cap layer 600, wherein the H ion implantation energy is 35keV, and the dose is 2.5×10 17 ions / cm 2 , with an injection angle of 7°. H ions are implanted to a preset depth to form an ion-implanted defect layer 201, the defect layer 201 is formed in the GaN buffer layer 200, and above the defect layer 201 is a remaining GaN buffer l...

Embodiment 2

[0105] like figure 2 As shown, a GaN single crystal wafer 100 with a size of 1 cm×1 cm, a thickness of 300 μm, and a (0001) crystal orientation Ga surface polishing is firstly provided.

[0106] like image 3 As shown, on the polished surface 100a of the GaN single crystal wafer 100, a 10 μm thick GaN buffer layer 200, a 150 nm thick GaN channel layer 300, and a 1 nm thick AlN insertion Layer 400, 30nm thick Al X Ga 1-X The N barrier layer 500, where x=0.25, and the GaN cap layer 600 with a thickness of 2nm constitute the first composite structure.

[0107] like Figure 4 As shown, the first composite structure is implanted with H ions from the direction of the GaN cap layer 600, wherein the H ion implantation energy is 75keV, and the dose is 3.5×10 17 ions / cm 2 , with an injection angle of 7°. H ions are implanted to a preset depth to form an ion-implanted defect layer 201, the defect layer 201 is formed in the GaN buffer layer 200, and above the defect layer 201 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com