Polymer-matrix composite dielectric material and plate capacitor

A technology of dielectric materials and polymer materials, applied in the direction of capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve problems such as solution provision, and achieve the effects of low leakage current, high dielectric constant, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

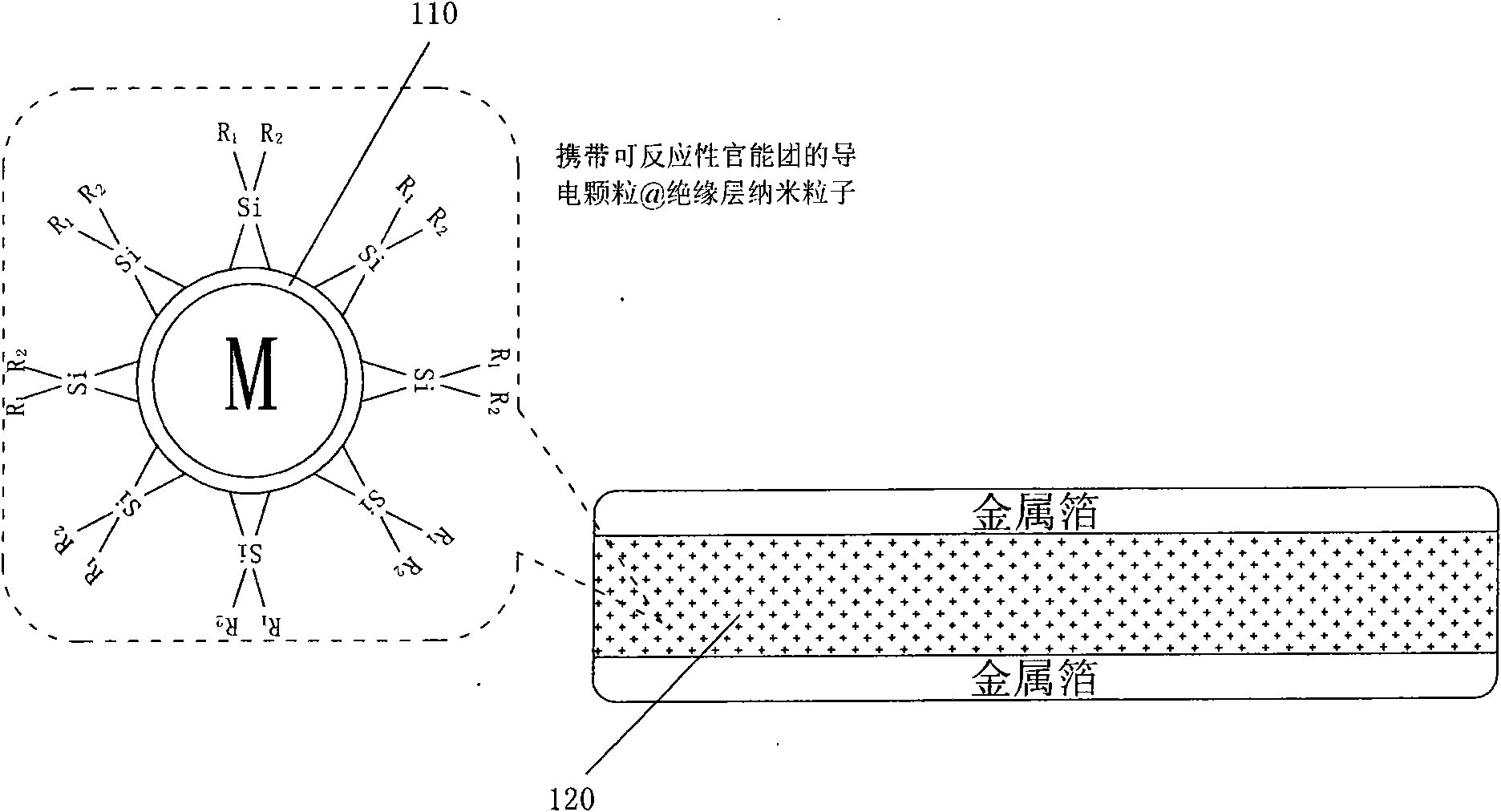

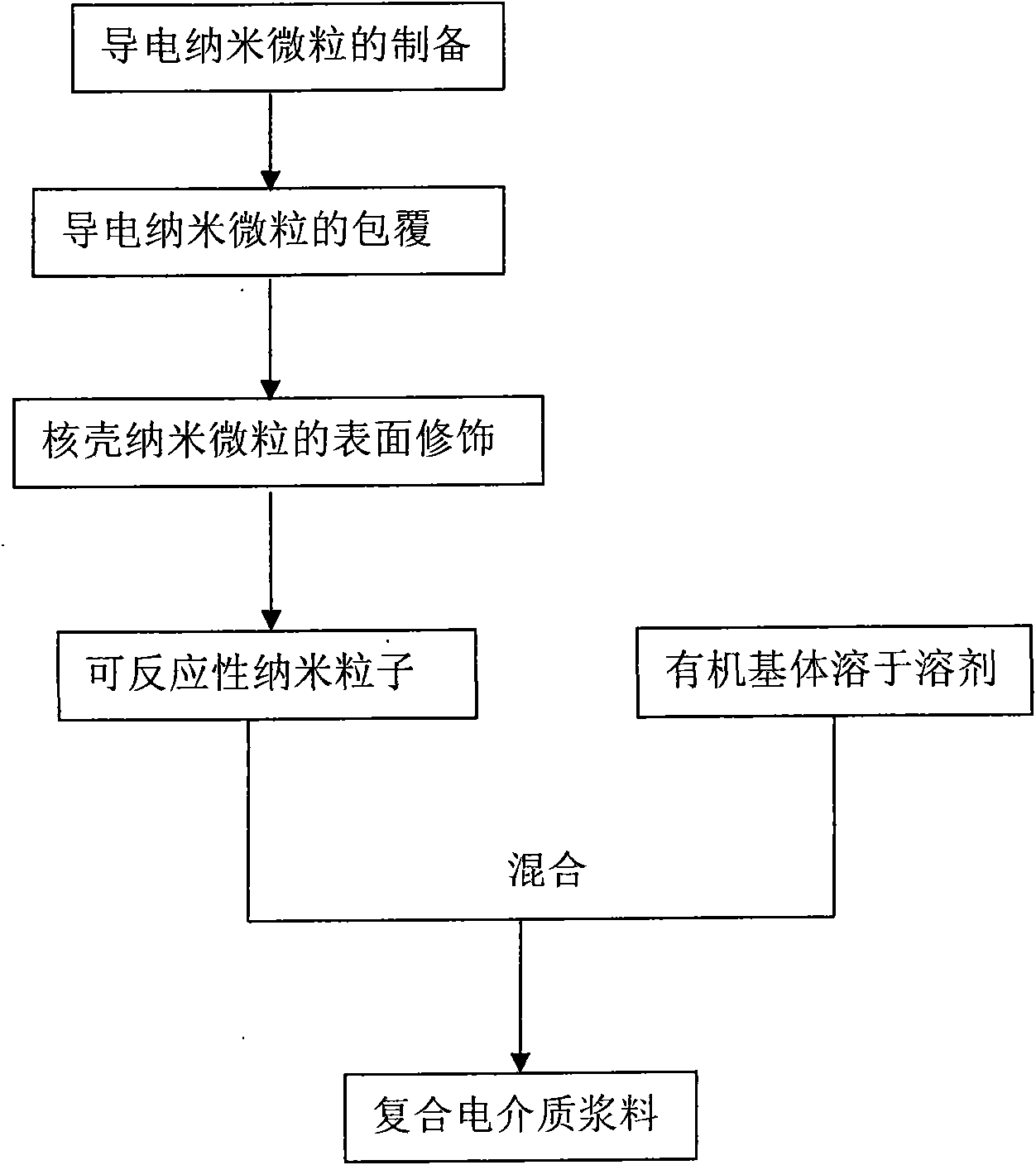

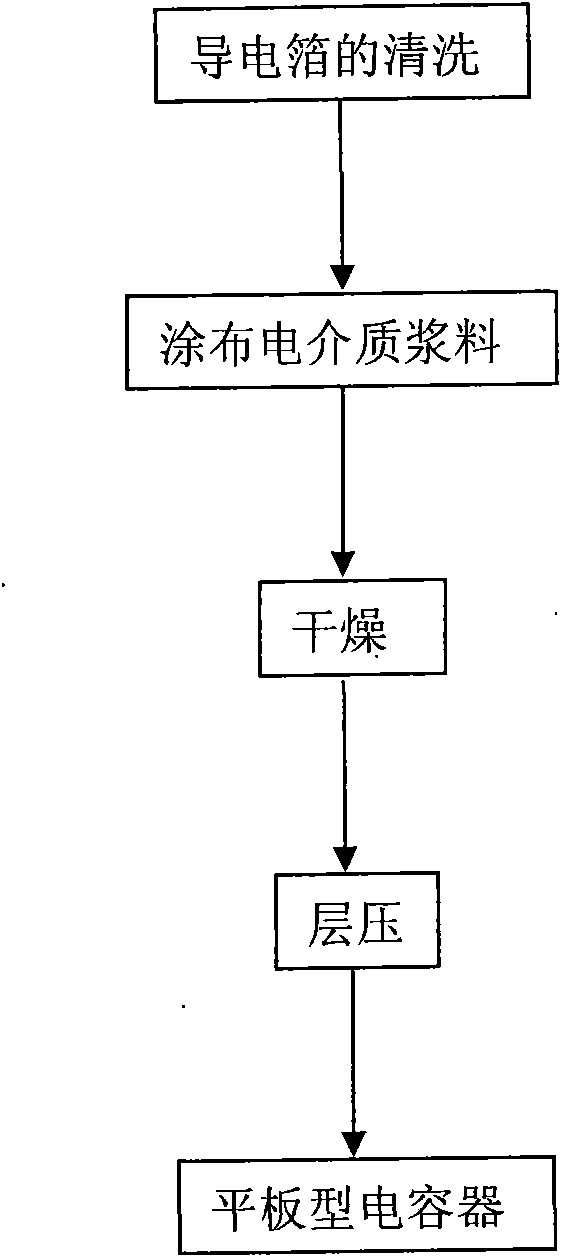

[0042] Example 1 Reactive Ag@SiO 2 Nanoparticle-filled polymer-based composite dielectric materials and their flat-plate capacitors:

[0043] Add 90 mg of silver nitrate to 490 mL of deionized water to prepare an aqueous solution. Add 10 mL of a 38.8 mM sodium citrate aqueous solution dropwise to the above solution heated to boiling, and control the addition within 2 min. Throughout the process, the reaction solution needs to be continuously stirred. Stop heating after 10 min and cool to room temperature. The reaction solution was centrifuged (at a speed of 500 rpm for 1 h), and the precipitate was removed to obtain a silver nanoparticle solution.

[0044] Take 1 mL of the above silver nanoparticle solution and mix it evenly with 250 mL of an aqueous solution of isopropanol (10% by volume). Quickly add 4 mL of ammonia water (concentration: 30 wt%) and 100 μL of tetraethyl silicate. The reaction solution was stirred at room temperature for 30 min, and then allowed to stand...

Embodiment 2

[0054] Example 2 Reactive Au@SiO 2 Polymer Matrix Composite Dielectric Material Filled with Nanoparticles and Its Flat Capacitor

[0055] Prepare 20mL containing HAuCl 4 and sodium citrate in water, both of which have a concentration of 2.5×10 -4 M. To it was added dropwise freshly prepared NaBH kept in an ice-water bath 4 Aqueous solution (concentration: 0.1M), 0.6mL in total. During the dropwise addition, constant stirring is required. The reaction is carried out at room temperature.

[0056] Take 4 mL of the above gold nanoparticle solution, add 20 mL of isopropanol, and add 0.5 mL of ammonia water (concentration: 30 wt%) and 25 μL of tetraethyl silicate under continuous stirring. The reaction solution was stirred and reacted at room temperature for 1 hour. After centrifugation (4000 rpm, 30 min), the resulting precipitate was washed with a water / ethanol mixed solvent with a volume ratio of 1:1. The centrifugation-washing process was repeated three times.

[0057] ...

Embodiment 3

[0062] Example 3 Reactive Cu@SiO 2 Filled Polymer Matrix Composite Dielectric Material and Its Flat Capacitor

[0063] Configure PVP, CuSO 4 , Ascorbic acid solution in ethylene glycol, the concentration is 0.30M, 0.10M, 0.25M respectively. Take 5mL of the ethylene glycol solution of PVP, heat and stir in a three-necked flask, and keep the temperature at 140°C, and at the same time add CuSO dropwise to it 4 and ascorbic acid in ethylene glycol, the total amount is 3mL. The dropping rate is 0.25mL / min or lower. Heat and stir, and react for 1 hour, then cool the system to 80°C and keep the temperature constant for 1 hour. After the reaction, the reaction system was cooled to room temperature, diluted to 30 mL with ethanol, and centrifuged. Separate and remove the supernatant. The resulting precipitate was washed with ethanol and separated again. This process was repeated at least 6 times, the rotating speed was 2000rpm, and the centrifugation time was 15min each time. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com