Dielectric composite material for fingerprint sensor induction layer and preparation method thereof

A fingerprint sensor and composite material technology, applied in the direction of acquiring/organizing fingerprints/palmprints, circuits, electrical components, etc., can solve problems such as low efficiency, high manufacturing cost, and complicated sensor packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0091] Preparation of Dielectric Composite Materials for Sensing Layer of Fingerprint Sensor

[0092] Small batch preparation method:

[0093] (1) take by weighing raw material according to embodiment 1;

[0094] (2) Mix the epoxy resin, the inorganic filler of the first type of dielectric, the inorganic filler of the second type of dielectric and the adhesion promoter at 150°C for 0.5 hours through a double-roller rubber mixer, and then add Release agent and flame retardant, knead for 1 minute; adjust the temperature to 80°C, add phenolic resin and catalyst, knead for 10 minutes until uniform, extrude into thin flakes, cool to room temperature, crush and make cakes to obtain The dielectric composite material used in the sensing layer of the fingerprint sensor is stored in a sub-zero refrigerator for future use.

[0095] Above-mentioned process parameter is the same as embodiment 1-1 in table 2.

[0096] Example 1-1 in Table 2, the number "1" before the "-" in "1-1" refers to...

Embodiment 40

[0103] The use of dielectric composite materials for the sensing layer of fingerprint sensors:

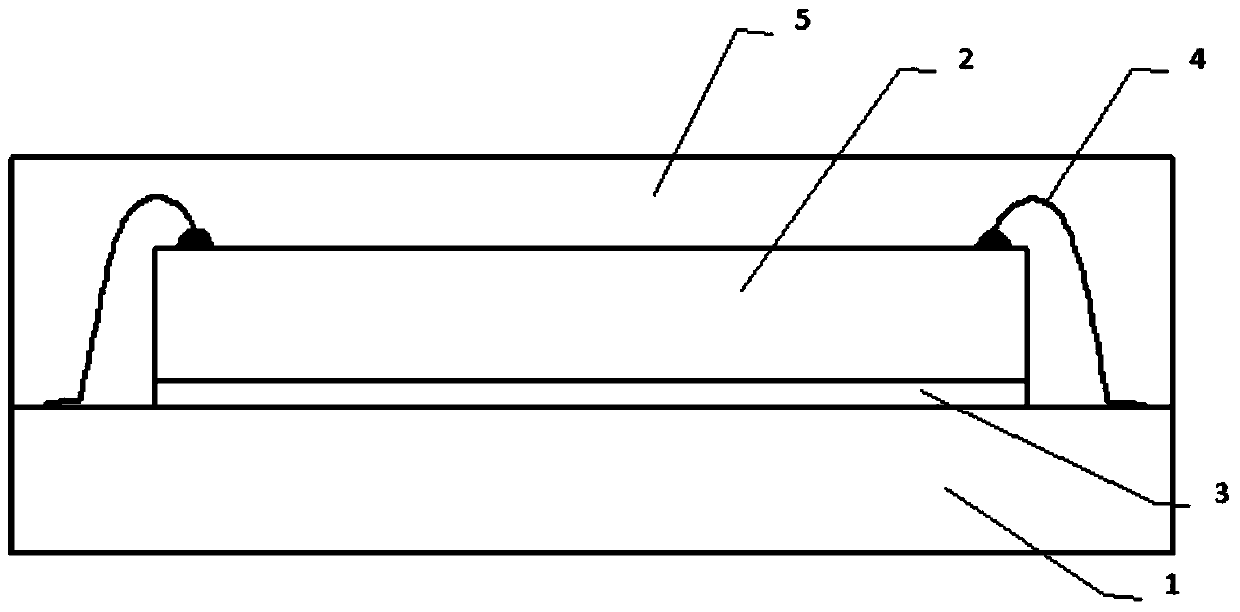

[0104] The dielectric composite material used for the sensing layer of the fingerprint sensor is covered on the fingerprint sensor chip by high-temperature molding injection molding (hydraulic method), and the dielectric composite material used for the sensing layer of the fingerprint sensor is completely cured by heating and curing, so that The fingerprint sensor chip can sense the electrical signal on the fingerprint, and finally recognize different fingerprint patterns, so it can be used very well on the fingerprint sensor (see figure 1 ).

[0105] figure 1 Among them, 1 is the packaging substrate; 2 is the sensor chip; 3 is the chip bonding material; 4 is the bonding wire; 5 is the dielectric composite material used in the fingerprint sensor sensing layer of the present invention.

Embodiment 41

[0107] Table 3. Properties of Dielectric Composite Materials Used in Sensing Layers of Fingerprint Sensors

[0108]

[0109]

[0110] The maximum particle size of the first and second types of dielectric inorganic fillers used in the sensing layer of the fingerprint sensor is <100 μm, and the average particle size is between 0.8 μm and 50 μm. When the dielectric composite materials are used in combination, the helical flow length of the dielectric composite material in the sensing layer of the prepared fingerprint sensor is longer and the flow effect is better.

[0111] Table 4. Encapsulation properties of dielectric composites for sensing layers of fingerprint sensors

[0112]

[0113]

[0114] The thickness of the dielectric composite material of the sensing layer of the fingerprint sensor is 200 μm, the curing condition is 170° C., and the curing time is 200 seconds. The composite materials prepared in Examples 5, 8, 10, 13, 16, 20, 24, 26, 28 and 37 have a har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com