Process for comprehensively utilizing waste tin-stripping solution

A process and tin stripping technology, which is applied in the field of comprehensive utilization of waste tin stripping water, can solve the problems of water quality that is difficult to meet the discharge standard, waste of water for treatment, and difficult to handle, so as to maximize economic and environmental benefits and solve the problem of secondary pollution , the effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

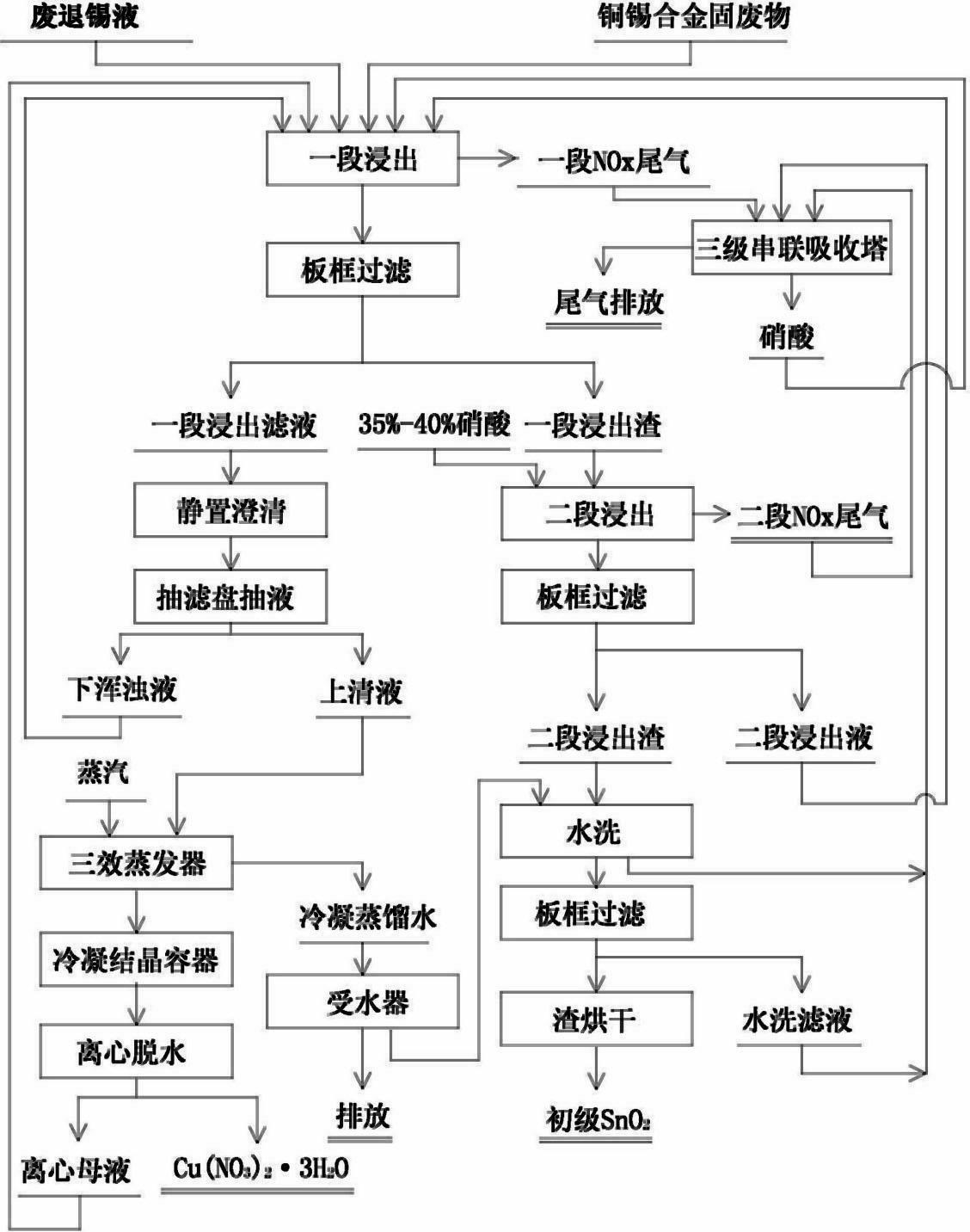

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] figure 1 Said, a comprehensive utilization process of waste tin stripping water; through the combination of two-stage leaching, co-current three-effect evaporation concentration crystallization and tail gas absorption acid production steps, the primary SnO 2 , industrial-grade copper nitrate crystals and nitric acid products; the specific process is as follows:

[0018] ① Two-stage leaching steps

[0019] First add 100 tons of waste tin stripping water (3.5% tin content, 0.5% copper content, 20% nitric acid) into a leaching tank, and then add 7.148 tons of electronic copper-tin alloy solid waste (95% copper, 3% tin content); Under stirring conditions, metal Cu and Sn are fully reacted with nitric acid, and a period of NOx tail gas is accompanied by generation; during the reaction process, Cu(NO 3 ) 2 , after tin dissolves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com