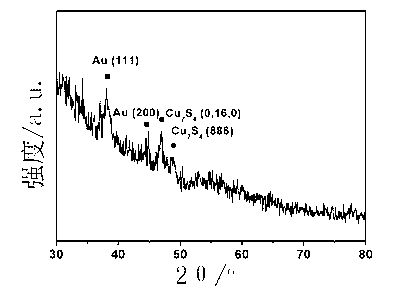

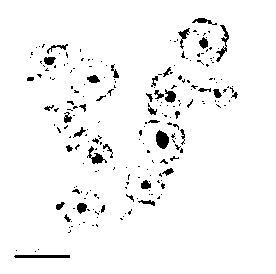

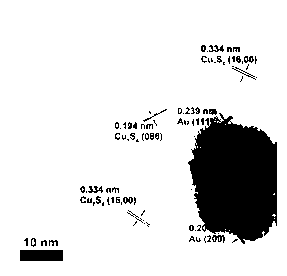

Nanometer composite material having gold/tetra-sulfide hepta-copper core-shell structure and preparation method thereof

A technology of nanocomposite material and core-shell structure, which is applied in the field of gold/copper heptasulfide core-shell structure nanocomposite material and its preparation, which can solve the problems of high preparation cost, complex synthesis method and harsh conditions, and achieve particle dispersion Good, uniform particle size distribution, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Take 25 ml of chloroauric acid aqueous solution with a mass fraction of 0.01% and heat it to boiling under stirring, then add 0.5 ml of a 1.0% sodium citrate aqueous solution, react for 15 min, and cool to room temperature to obtain a gold nanoparticle sol solution.

[0017] 2) The gold sol solution (20 ml) prepared in step 1) was centrifuged at 6000 r / min for 20 min, the supernatant was removed, and 10 ml of deionized water was added to the gold nanoparticles in the lower layer to disperse to obtain Gold nanoparticles solution.

[0018] 3) Take 50 ml of copper nitrate solution with a concentration of 0.005 mol / L, add 0.5 g of polyvinylpyrrolidone to it to obtain a copper nitrate mixed solution, and add 2.5 ml of the gold nanoparticle solution prepared in step 2) while stirring at a constant temperature of 80 °C , and then added 0.01 ml of hydrazine hydrate with a mass fraction of 99%. After reacting for 2 min, the product was separated and washed three times with de...

Embodiment 2

[0022] 1) Take 25 ml of chloroauric acid aqueous solution with a mass fraction of 0.01% and heat it to boiling under stirring, then add 0.5 ml of a 1.0% sodium citrate aqueous solution, react for 40 min, and cool to room temperature to obtain a gold nanoparticle sol solution.

[0023] 2) The gold sol solution (20 ml) prepared in step 1) was centrifuged at a speed of 10,000 r / min for 10 min, the supernatant was removed, and 10 ml of deionized water was added to the gold nanoparticles in the lower layer for dispersion to obtain Gold nanoparticles solution.

[0024] 3) Take 50 ml of copper nitrate solution with a concentration of 0.05 mol / L, add 5 g of polyvinylpyrrolidone to it to obtain a copper nitrate mixed solution, and add 5 ml of the gold nanoparticle solution prepared in step 2) while stirring at a constant temperature of 80 °C , and then added 0.05 ml of hydrazine hydrate with a mass fraction of 99%. After 40 min of reaction, the product was separated and washed with dei...

Embodiment 3

[0027] 1) Take 50 ml of chloroauric acid aqueous solution with a mass fraction of 0.01% and heat it to boiling under stirring, then add 1 ml of 1.0% sodium citrate aqueous solution, react for 60 min, and cool to room temperature to obtain a gold nanoparticle sol solution.

[0028] 2) Centrifuge 50 ml of the gold sol solution prepared in step 1) at a speed of 12000 r / min for 5 min, remove the supernatant, and add 25 ml of deionized water to the lower layer of gold nanoparticles for dispersion to obtain gold nanoparticles particle solution.

[0029] 3) Take 50 ml of copper nitrate solution with a concentration of 0.1 mol / L, add 10 g of polyvinylpyrrolidone to it to obtain a copper nitrate mixed solution, and add 25 ml of the gold nanoparticle solution prepared in step 2) while stirring at a constant temperature of 20 °C , and then added 0.1 ml of hydrazine hydrate with a mass fraction of 99%. After reacting for 60 min, the product was separated and washed with deionized water th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com