Preparation method of carbon/carbon-copper composite material

A technology of carbon composite materials and composite materials, which is applied in the field of preparation of carbon/carbon-copper composite materials, can solve problems such as unsuitable carbon-copper dual-phase materials, high equipment requirements, and reduced thermal conductivity of materials, so as to avoid Difficult pressurization, high degree of crystallization, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

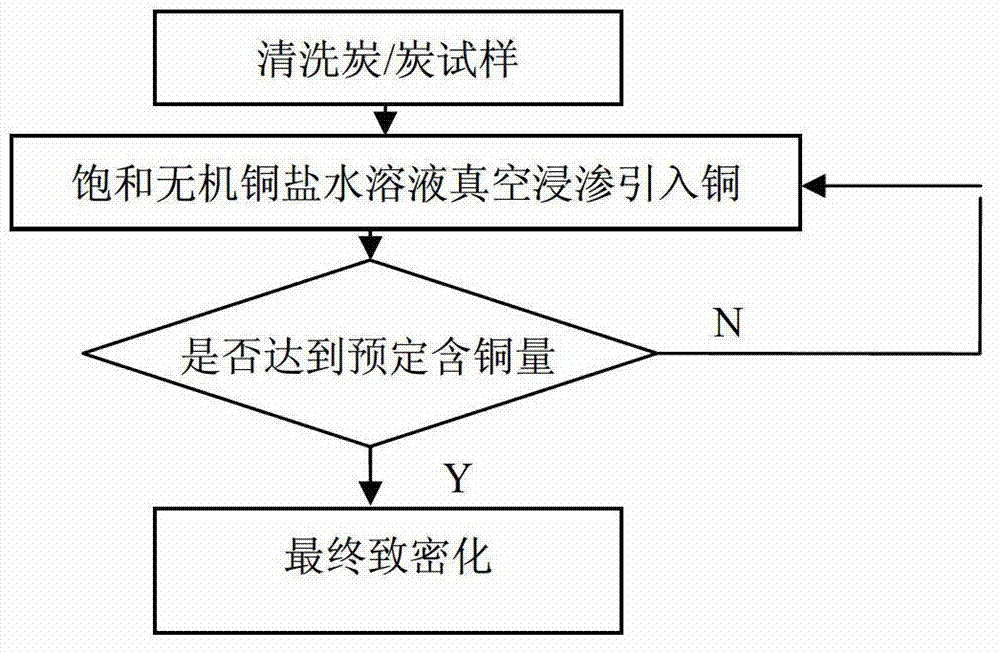

[0024] The present embodiment is a kind of preparation method of carbon / carbon-copper composite material, and concrete process is:

[0025] Step 1: Clean the sample: the graphitized and density of 0.60g / cm 3 The carbon / carbon composite samples were ultrasonically cleaned in absolute ethanol for 20 min. Place the cleaned carbon / carbon composite material sample in an electric blast drying oven, and dry it at 60°C for 10 hours before use;

[0026] Step 2: Vacuum impregnation of saturated inorganic copper salt solution to introduce copper: the specific process is:

[0027] a. Put the carbon / carbon composite material sample cleaned in step 1 into a vacuum tank, evacuate to -0.08MPa, and pass in a saturated copper sulfate aqueous solution with a temperature of 60°C, and wait for the carbon / carbon composite material sample to Immersed completely in the solution, take it out after 20 minutes and use a polytetrafluoroethylene plate to scrape off the copper sulfate pentahydrate attach...

Embodiment 2

[0033] Step 1: Clean the sample: the graphitized and density of 0.70g / cm 3 The carbon / carbon composite samples were ultrasonically cleaned in absolute ethanol for 10 min. Place the cleaned carbon / carbon composite material sample in an electric blast drying oven, and dry it at 80°C for 24 hours before use;

[0034] Step 2: Vacuum impregnation of saturated inorganic copper salt solution to introduce copper: the specific process is:

[0035] a. Put the carbon / carbon composite material sample cleaned in step 1 into a vacuum tank, evacuate to -0.10MPa, and pass in a saturated copper nitrate aqueous solution with a temperature of 85°C, and wait for the carbon / carbon composite material sample to Immersed completely in the solution, take it out after 30 minutes and use a polytetrafluoroethylene board to scrape off the copper nitrate trihydrate attached to the surface. Place the composite material sample immersed in saturated copper nitrate aqueous solution in an electric blast dryin...

Embodiment 3

[0041] Step 1: Clean the sample: the graphitized and density of 1.40g / cm 3 The carbon / carbon composite samples were ultrasonically cleaned in absolute ethanol for 30 min. Place the cleaned carbon / carbon composite material sample in an electric blast drying oven, and dry it at 95°C for 30 hours before use;

[0042] Step 2: Vacuum impregnation of saturated inorganic copper salt solution to introduce copper: the specific process is:

[0043] a. Put the carbon / carbon composite material sample cleaned in step 1 into a vacuum tank, evacuate to -0.09MPa, and pass in a saturated copper sulfate aqueous solution with a temperature of 95°C, and wait for the carbon / carbon composite material sample to Immersed completely in the solution, take it out after 15 minutes and use a polytetrafluoroethylene board to scrape off the copper sulfate pentahydrate attached to the surface. The composite material sample immersed in a saturated copper sulfate aqueous solution was placed in an electric bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com