Porous copper organic framework material for CO2 adsorption and separation and preparation method of porous copper organic framework material

A metal-organic framework, porous copper technology, applied in separation methods, adsorption, organic chemistry, etc., can solve problems such as high cost and complicated steps, and achieve the effects of good storage performance, enhanced adsorption capacity, and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

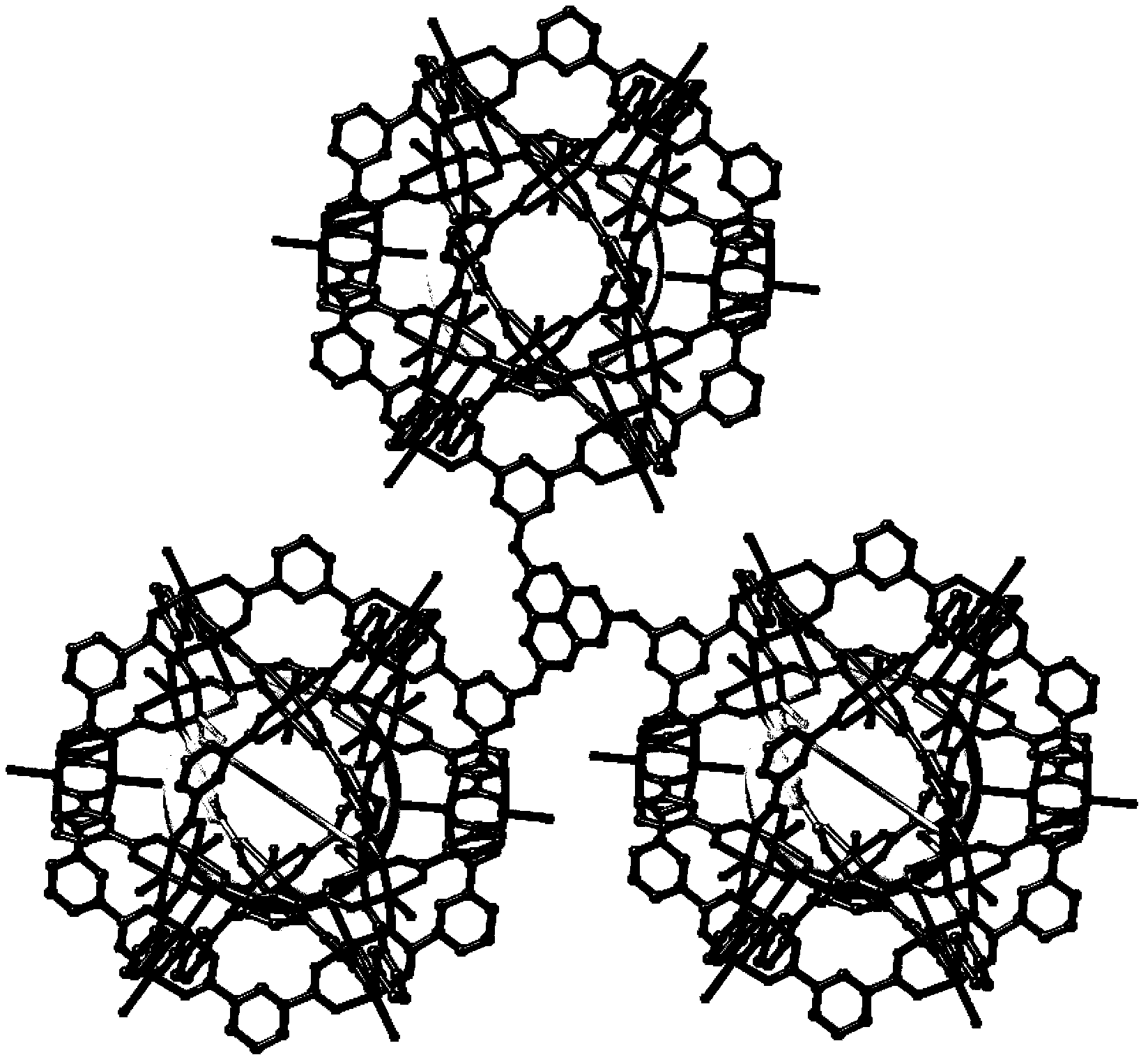

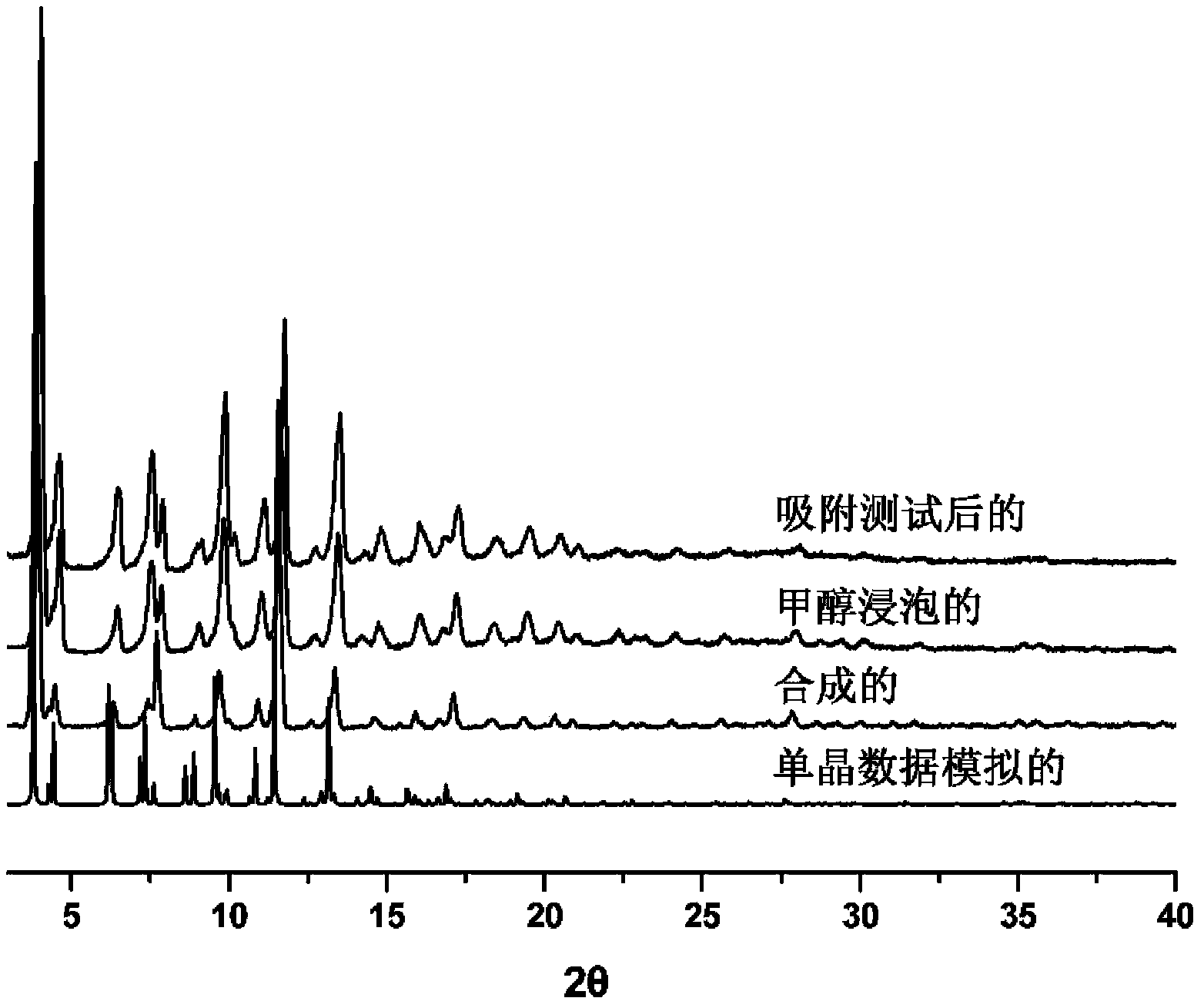

[0023] will be 4.0×10 -4 mol copper nitrate hexahydrate and 7.0×10 -5 mol organic ligand TDPAH is dissolved in 2.1×10 -2 mol N,N'-dimethylacetamide, 2.8×10 -2 mol dimethyl sulfoxide and 5.5×10 -2 In a mixed solvent composed of mol water, react at 100°C for 72 hours to obtain a crude porous copper metal-organic framework material; wash the crude porous copper metal-organic framework material with methanol and then dry it at 80°C to obtain a blue octahedral crystal—— The yield of the purified porous copper metal-organic framework was 89% (calculated based on the amount of organic ligand TDPAH).

[0024] The unit cell parameters of porous copper MOFs are 28.1527, 28.1527, 41.0701, 90, 90, 90. Activate the dried and purified porous copper metal organic framework, soak in methanol for 2 days, filter and vacuumize for 10 hours with an ordinary oil pump, and the vacuum degree is less than 10 -3 mmHg, remove the end group H coordinated with the copper ion 2 O molecules, so that ...

Embodiment 2

[0031] will be 2.8×10 -5 mol copper nitrate hexahydrate and 7.0×10 -5 mol organic ligand (TDPAH) dissolved in 1.6×10 -2 mol N,N'-dimethylacetamide, 1.9×10 -2 mol DMSO and 3.5×10 -2 In a mixed solvent composed of mol water, react at 100°C for 72 hours to obtain a crude porous copper metal-organic framework material; wash the crude porous copper metal-organic framework material with methanol and then dry it at 80°C to obtain a blue octahedral crystal—— Purified porous copper metal-organic framework with a yield of 12% (calculated based on the organic ligand TDPAH). Activate the dried porous copper metal organic framework, soak in methanol for 2 days, filter and vacuumize for 10 hours with an ordinary oil pump, and the vacuum degree is less than 10 -3 mmHg, remove the end group H coordinated with the copper ion 2 O molecules, so that it becomes an active metal center, and a porous copper metal organic framework material is obtained.

Embodiment 3

[0033] will be 7.0×10 -4 mol copper nitrate hexahydrate and 7.0×10 -5 mol organic ligand (TDPAH) at 6.0×10 -2 mol N,N'-dimethylacetamide, 4.5×10 -2 mol dimethyl sulfoxide and 10.5×10 -2 In a mixed solvent composed of mol water, react at 100°C for 72 hours to obtain a crude porous copper metal-organic framework material; wash the crude porous copper metal-organic framework material with methanol and then dry it at 80°C to obtain a blue octahedral crystal—— Purified porous copper metal-organic framework material with a yield of 83% (calculated based on the organic ligand TDPAH). Activate the dried porous copper metal organic framework, soak in methanol for 2 days, filter and vacuumize for 10 hours with an ordinary oil pump, and the vacuum degree is less than 10 -3 mmHg, remove the end group H coordinated with the copper ion 2 O molecules, so that it becomes an active metal center, and a porous copper metal organic framework material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com