Preparation method of metal-organic framework material for adsorbing separation of carbon dioxide/ methane

A metal-organic framework and carbon dioxide technology, applied in separation methods, chemical instruments and methods, through adsorption, etc., can solve problems such as complicated steps and increase the cost of use of adsorption materials, and achieve low pressure, good use tolerance, and high operating technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides a method for preparing a metal-organic framework material that absorbs and separates carbon dioxide / methane, and in one embodiment, includes the following steps:

[0024] (1) Mix 0.46~1.16 mol / L copper nitrate aqueous solution and 0.23~0.58 mol / L trimesenetricarboxylic acid (1,3,5-Benzenetricarboxylic Acid, C 9 h 6 o 6 , abbreviated as H 3 btc) ethanol solution is mixed, fully stirred and then added to a stainless steel reactor with a polytetrafluoroethylene liner to seal, and the crystallization temperature is controlled at 60~150°C and the crystallization time is 12~24 hours for solvothermal reaction;

[0025] (2) Open the stainless steel reaction kettle, filter, wash with methanol and deionized water in sequence, and dry at 80~105°C to obtain blue crystals;

[0026] (3) Vacuumizing the blue crystal at 150-200° C. to obtain a copper-containing metal-organic framework material.

[0027] Preferably, the temperature in the step (3) ...

Embodiment 1

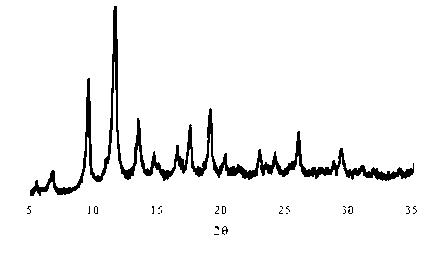

[0033] Weigh a certain amount of Cu(NO 3 ) 2 ·3H 2 O, dissolved in a certain amount of deionized water, prepared 25ml Cu(NO 3 ) 2 ·3H 2 O aqueous solution, marked as solution Ⅰ; prepare 25ml of H with a concentration of 0.58 mol / L 3 The ethanol solution of btc is marked as solution Ⅱ; mix solution Ⅰ and solution Ⅱ, stir well, put it into a 100ml stainless steel reaction kettle with polytetrafluoroethylene lining, crystallize at 95°C for 15 hours, filter and then Wash three times with methanol and deionized water, 50ml each time, stir thoroughly for 10min, and dry at 105°C for 10 hours to obtain blue crystals. The obtained blue crystals were vacuumized at 175°C for 10 hours, and the measured specific surface area was 1136m 2 / g, X-ray diffraction pattern (XRD) such as figure 1 As shown, characteristic peaks appear at 2θ angles of 6.72°, 9.56°, 11.70°, 13.48°, 14.70°, 16.5°, and 17.54° in the figure, indicating that the material has a typical metal-organic framework mater...

Embodiment 2

[0035] The difference from Example 1 is: crystallize at 60°C for 15 hours in a stainless steel reaction kettle lined with polytetrafluoroethylene, filter and wash with methanol and deionized water three times in sequence, 50ml each time, and fully stir for 10min , dried at 80°C for 2 hours to obtain blue crystals. The obtained blue crystals were subjected to vacuum treatment at 150°C for 3 hours, and the measured specific surface area was 539m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com