Enhanced surfaces, coatings, and related methods

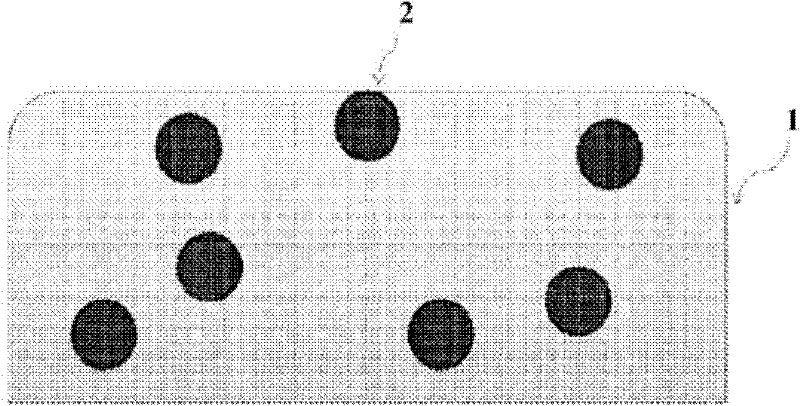

A surfactant, average cross-section technology, applied in the field of molded articles, to solve problems such as efficacy limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0220] Non-limiting example 1 : Surface plasmons are the excitation of free electrons on metal surfaces under photoexcitation conditions; many semiconductor and organic semiconductor systems now employ plasmonic passive and active materials. Using the embedding methods described herein (or the polymer softening methods described in the related patent applications incorporated herein by reference in their entirety), embedding particles, molecules, etc., such as nanowires and nanocones, to form passive optical nanoantennas , the nanoantenna can alter or improve the absorption of radiation, photons and / or light incident into the OPV.

example 2

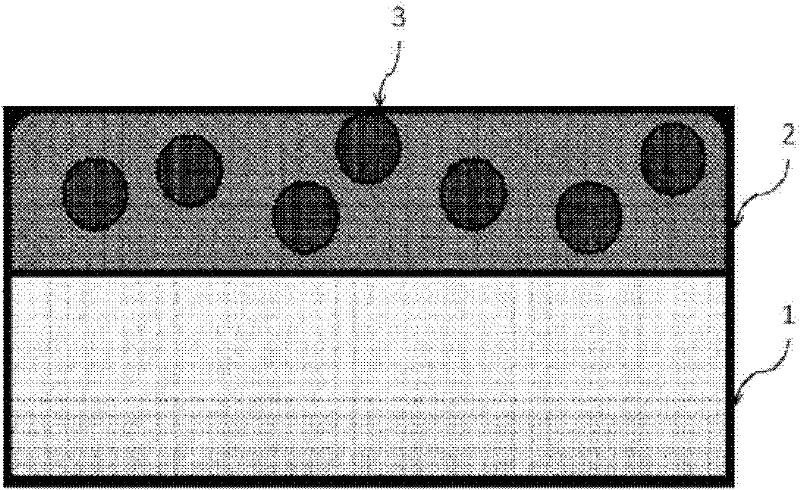

[0221] Non-limiting example 2 : the method disclosed in the present invention can make TiO 2 The interlayer of particles is embedded in and / or on top of the OPV. Such particles and layers reduce recombination losses and dramatically increase device efficiency (up to 160%). TiO 2 Light blocking layers are beneficial, for example, in organic dye-sensitized solar cells.

example 3

[0222] Non-limiting example 3 : The method disclosed in the present invention can be applied to luminescent solar concentrators (LSC). In some embodiments, a polymer softening solution (described in a related patent application incorporated herein by reference) is capable of temporarily altering the polymer substrate surface so that particles can be embedded into the polymer surface in the LSC. These particles can be, but are not limited to, scatterers, concentrators, nanoantennas, nanotubes, butt couplers, mirrors, focusing elements, refractive elements, mirrors, or waveguides that facilitate the absorption of incident solar radiation and its coupling into the interior of the LSC Other structures in the mold. This solution-based treatment of polymers by embedding particle inclusions into the polymer surface can alter the material's surface impedance, surface conductivity, refractive index, extinction, and / or optical transparency, resulting in improved device performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com