Electrode materials and all-vanadium redox flow battery containing electrode materials

An all-vanadium redox flow battery and electrode material technology, which is applied in the direction of regenerative fuel cells, electrode manufacturing, battery electrodes, etc., can solve the problems of battery performance degradation, increase the difficulty of battery assembly, and affect the service life of electrode batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Carbon cloth was mixed with 6mol / L HNO at a volume ratio of 1:1 3 and 3mol / L of H 2 SO 4 After soaking in mixed acid for 10min, in 0.1mol / L Fe(NO 3 ) 3 Soak in xylene solution for 12 hours, take it out, and dry it at room temperature.

[0027] The above-mentioned dry carbon is arranged in the high-temperature reaction furnace that 2.5g ferrocene catalyst is placed in the furnace mouth, 2 Under gas protection, the reaction furnace was heated up. When the temperature in the furnace rises to 750°C, the C 2 h 2 gas while controlling C 2 h 2 / N 2 The flow ratio is 5.0. After reacting for 10min, close the C 2 h 2 . in N 2 The reaction furnace was cooled to room temperature under gas protection, and N was controlled during the cooling process. 2 The gas flow is 50 sccm, and the carbon cloth that can be used for the electrode of the all-vanadium redox flow battery is obtained with carbon nanotubes deposited on the surface.

Embodiment 2

[0029] The carbon felt was mixed with 6 mol / L HNO at a volume ratio of 1:1 3 and 3mol / L of H 2 SO 4 After soaking in mixed acid for 80min, in 5.2mol / L Fe(NO 3 ) 3 Soak in xylene solution for 12 hours, take it out, and dry it at room temperature.

[0030] The above-mentioned dry carbon is arranged in the high-temperature reaction furnace that 2.5g ferrocene catalyst is placed in the furnace mouth, 2 Under gas protection, the reaction furnace was heated up. When the temperature in the furnace rises to 750°C, the C 2 h 2 gas while controlling C 2 h 2 / N 2 The flow ratio is 0.5. After reacting for 120min, close the C 2 h 2 . in N 2 The reaction furnace was cooled to room temperature under gas protection, and N was controlled during the cooling process. 2 The gas flow is 50 sccm, and the carbon felt that can be used for the electrode of the all-vanadium redox flow battery is obtained with carbon nanotubes deposited on the surface.

Embodiment 3

[0032] The graphite felt was mixed with 6 mol / L HNO at a volume ratio of 1:1 3 and 3mol / L of H 2 SO 4 After soaking in mixed acid for 50min, in 2.5mol / L Fe(NO 3 ) 3 Soak in xylene solution for 12 hours, take it out, and dry it at room temperature.

[0033] The above-mentioned dry carbon is arranged in the high-temperature reaction furnace that 2.5g ferrocene catalyst is placed in the furnace mouth, 2 Under gas protection, the reaction furnace was heated up. When the temperature in the furnace rises to 750°C, the C 2 h 2 gas while controlling C 2 h 2 / N 2 The flow ratio is 2.5. After reacting for 60min, close the C 2 h 2 . in N 2 The reaction furnace was cooled to room temperature under gas protection, and the N2 gas flow was controlled to be 50 sccm during the cooling process, so as to obtain a graphite felt with carbon nanotubes deposited on the surface that can be used for the electrode of an all-vanadium redox flow battery.

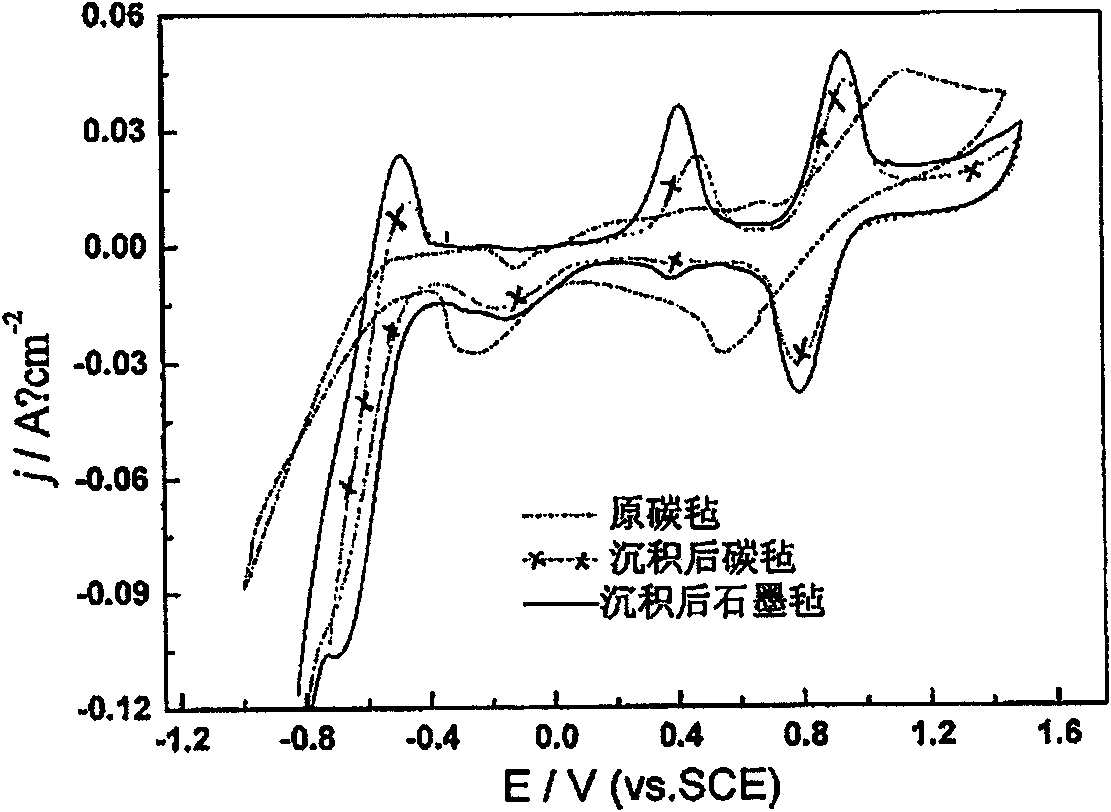

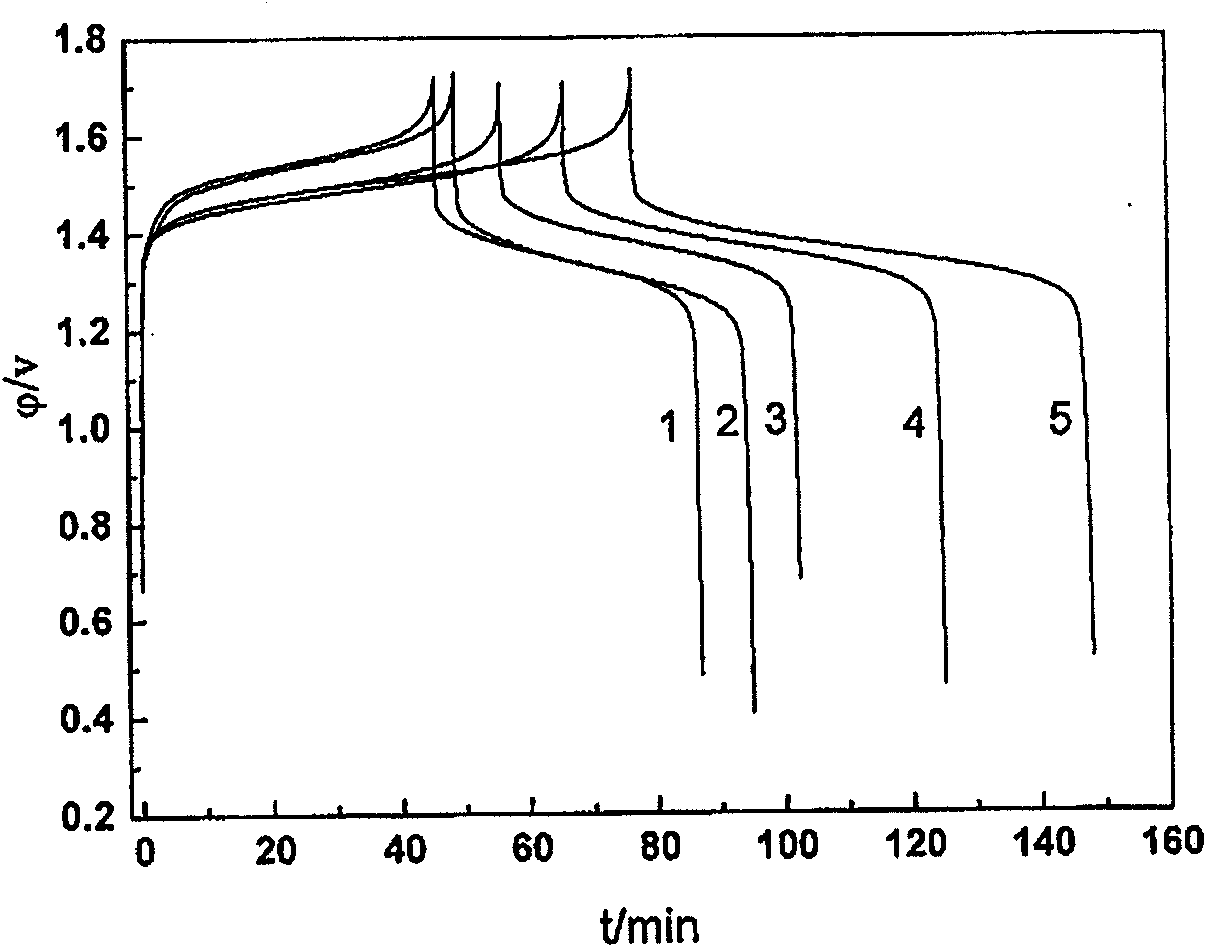

[0034] figure 1 Comparison of cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com