Ore dressing collector and preparation method thereof

A technology of collectors and surfactants, which is applied in the field of low-temperature ore dressing collectors and their preparation, can solve the problems of high energy consumption, high production costs, and low grades of concentrates, so as to improve product recovery and product grades , The effect of reducing the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

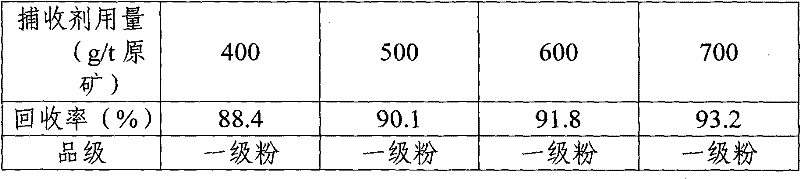

Examples

Embodiment 1

[0021] To prepare the product of the present invention of 1000kg, get oleic acid 760kg, sodium dodecylsulfonate 20kg, sodium cetylsulfonate 30kg, N, N-dimethylamide-dimethyl sulfate 55kg, POCl 3 65kg, PCl 3 70kg, its preparation method is:

[0022] 1. Pour oleic acid into the stirring tank, slowly add sodium dodecylsulfonate and sodium hexadecylsulfonate, and stir while adding. This step is carried out at 20-30°C;

[0023] 2. Add the mixed solution in the previous step into 1mol / L hydrochloric acid solution, use graphite and iron as electrodes, graphite as anode, iron as cathode, anode current density is 1000A / m 2 Under the conditions of electrolysis, the electrolysis temperature is 35 ℃, and the electrolysis time is 0.5h;

[0024] 3. After the electrolysis, the mixed liquid is introduced into the separator, and the oil phase is separated from the water phase to obtain the oil phase;

[0025] 4. Add N,N-dimethylamide-dimethyl sulfate and POCl to the obtained oil phase 3 , ...

Embodiment 2

[0027] To prepare the product of the present invention of 1000kg, get oleic acid 780kg, cetyl sodium sulfonate 25kg, didodecyldimethylammonium chloride 20kg, N, N-dimethylamide-dimethyl sulfate 50kg, PCl 3 125kg, its preparation method is:

[0028] 1. Pour oleic acid into the stirring tank, slowly add sodium cetyl sulfonate and didodecyl dimethyl ammonium chloride, and stir while adding. This step is carried out at 20-30 °C;

[0029] 2. Add the mixed solution in the previous step into 1mol / L hydrochloric acid solution, use graphite and iron as electrodes, graphite as anode, iron as cathode, anode current density is 1200A / m 2 Under the conditions of electrolysis, the electrolysis temperature is 30 ℃, and the electrolysis time is 1h;

[0030] 3. After the electrolysis, the mixed liquid is introduced into the separator, and the oil phase is separated from the water phase to obtain the oil phase;

[0031] 4. Add N,N-dimethylamide-dimethyl sulfate and PCl to the obtained oil pha...

Embodiment 3

[0033] To prepare the product of the present invention of 1000kg, get oleic acid 780kg, dodecyltrimethylammonium chloride 40kg, N, N-dimethylamide-dimethyl sulfate 60kg, PCl 5 120kg, its preparation method is:

[0034] 1. Pour oleic acid into the stirring tank, slowly add dodecyltrimethylammonium chloride, and stir while adding. This step is carried out at 20-30°C;

[0035] 2. Add the mixed solution in the previous step into 1mol / L hydrochloric acid solution, use graphite and iron as electrodes, graphite as anode, iron as cathode, anode current density is 1400A / m 2 Under the conditions of electrolysis, the electrolysis temperature is 25 ℃, and the electrolysis time is 1.5h;

[0036] 3. After the electrolysis, the mixed liquid is introduced into the separator, and the oil phase is separated from the water phase to obtain the oil phase;

[0037] 4. Add N,N-dimethylamide-dimethyl sulfate and PCl to the obtained oil phase 5 , heated up to 55°C, and reacted for 20 minutes to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com