Water system press-in grouting material used for iron making hot blast heater system and preparation method thereof

A technology of grouting materials and hot blast stoves, applied in the field of refractory materials, can solve the problems of furnace lining damage, ironmaking output decline, economic loss, etc., achieve thermal shock resistance and erosion resistance, simple preparation method, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

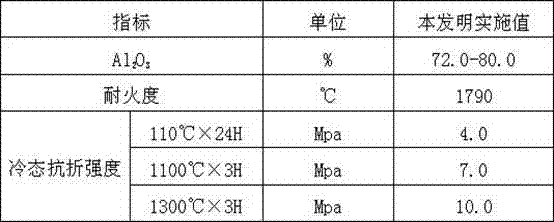

[0020] Weigh 78 kg of high alumina bauxite, 6 kg of corundum fine powder, 4 kg of α-alumina fine powder, 3 kg of raw clay, 2 kg of kyanite, Y 2 o 3 (yttrium oxide) 0.6 kg; La 2 o 3 (lanthanum oxide) 0.9 kg, dextrin 1 kg, silica gel powder 2.5 kg, silica fume 1 kg, carboxymethyl cellulose 0.5 kg; sodium tripolyphosphate 0.25 kg, sodium hexametaphosphate 0.25 kg. First, mix super-grade high-bauxite, corundum fine powder, α-alumina micro-powder, raw clay, bentonite, and kyanite according to the formula ratio, and stir evenly; then mix the mixture of yttrium oxide and lanthanum oxide, dextrin, silica gel powder, silica fume , Carboxymethylcellulose sodium tripolyphosphate and sodium hexametaphosphate mixture, mixed according to the formula ratio, and stirred evenly; the above-mentioned twice-mixed materials were added to a double-helix mixer, stirred evenly, and then discharged and packaged for storage.

[0021] When using, add water according to 22% of the total weight, a...

Embodiment 2

[0024] Weigh 76 kg of super-bauxite, 9 kg of corundum fine powder, 3 kg of α-alumina fine powder, 1.5 kg of raw clay, 1.5 kg of bentonite, 1.5 kg of kyanite, Y 2 o 3 (Yttria) 0.52 kg 、 La 2 o 3 (lanthanum oxide) 0.78 kg, dextrin 1 kg, silica gel powder 2.7 kg, silica fume 1.2 kg, carboxymethyl cellulose 0.5 kg, sodium tripolyphosphate 0.25 kg, sodium hexametaphosphate 0.35 kg, prepared in the same manner as in Example 1 The method is to prepare the water system press-in grouting material used in the ironmaking hot blast stove system according to the present invention.

[0025] When using, add water according to 21% of the total weight, stir for more than 15 minutes until it is uniform, and then use it.

[0026] After adding 21% water according to the formula and stirring evenly, the detection performance index is: Al 2 o 3 76.08%, refractoriness 1790℃, cold flexural strength: 110℃×24H 4.6Mpa; 1100℃×3H 8.0Mpa; 1300℃×3H 11.1Mpa.

Embodiment 3

[0028] Weigh 75 kg of high alumina bauxite, 8 kg of corundum fine powder, 4 kg of α-alumina fine powder, 3 kg of bentonite, 2 kg of kyanite, Y 2 o 3(Yttria) 0.64kg 、La 2 o 3 (lanthanum oxide) 0.96kg, dextrin 1.1kg, silica gel powder 2.9kg, silica fume 1.3kg, methylcellulose 0.4kg, sodium tripolyphosphate 0.3kg, sodium hexametaphosphate 0.4kg, the same preparation method as in Example 1 The water system press-in grouting material used for ironmaking hot blast stove system according to the present invention is prepared.

[0029] When using, add water according to 21% of the total weight, stir well and use it.

[0030] After adding 21% water according to the formula and stirring evenly, the detection performance index is: Al 2 o 3 75.95%, refractoriness 1790℃, cold flexural strength: 110℃×24H 4.9Mpa; 1100℃×3H 7.3Mpa; 1300℃×3H 10.6Mpa.

[0031] The water-system press-in grouting material of the invention has good performance, high low-temperature strength, does not d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com