High-temperature protective coating for high-carbon steel billet and application thereof

A technology for protective coatings and high carbon steel, applied in the field of refractory coatings, can solve the problems of limited high temperature oxidation resistance, large expansion coefficient of magnesia, slow application process of oxidation coatings, etc., to improve thermal shock stability and dense coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A high-temperature protective coating for high-carbon steel slabs and its application

[0031] (1) Formula composition

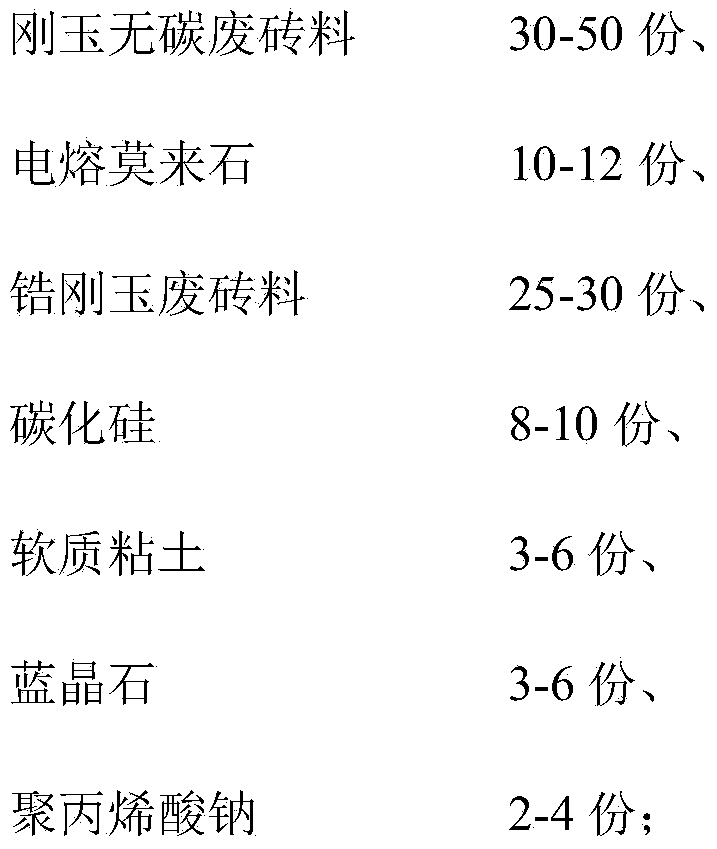

[0032] The dry powder is composed as follows in parts by weight:

[0033]

[0034]

[0035] The binder is composed of a solid composite binder and a liquid composite binder. The solid composite binder is composed of dextrin and sodium lignosulfonate in a weight ratio of 2.2:1, and its addition amount is 4% of the total weight of the dry powder; The liquid composite binder is composed of aluminum sol, silica sol and liquid aluminum dihydrogen phosphate in a weight ratio of 1:0.4:0.6, and its added amount is 3% of the total weight of the dry powder.

[0036] (2) Preparation method

[0037] Grind each dry powder first, pass through a 325-mesh sieve, take the sieve, weigh it according to the weight ratio, and put it into the mixer together with the solid composite binder to mix, add an appropriate amount of water to stir, stir evenly, an...

Embodiment 2

[0042] Example 2 A high-temperature protective coating for high-carbon steel slabs and its application

[0043] (1) Formula composition

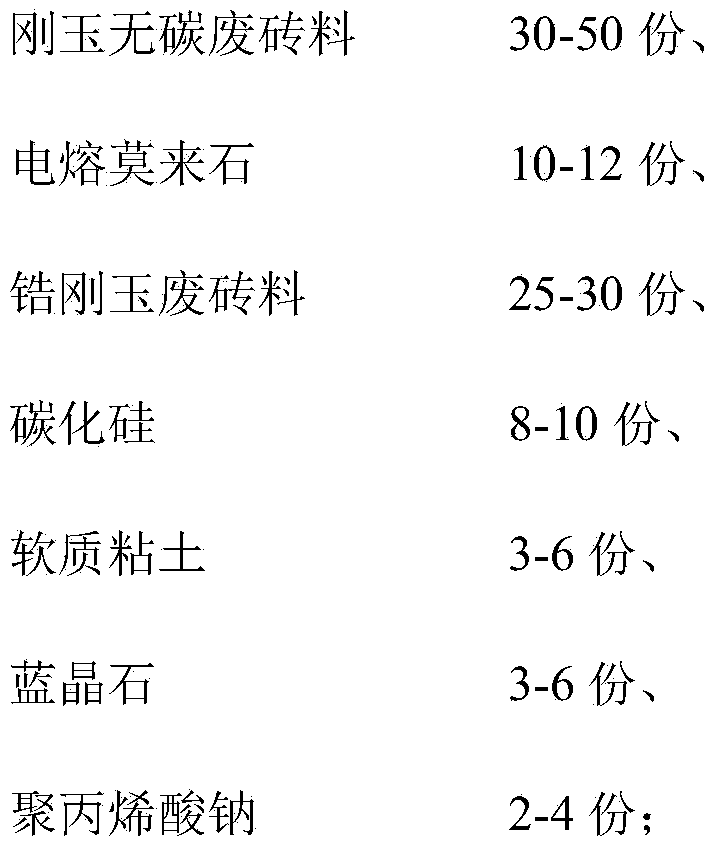

[0044]The dry powder is composed as follows in parts by weight:

[0045]

[0046] The binder is composed of a solid composite binder and a liquid composite binder. The solid composite binder is composed of dextrin and sodium lignosulfonate in a weight ratio of 2.2:1, and its addition amount is 5% of the total weight of the dry powder; The liquid composite binder is composed of aluminum sol, silica sol and liquid aluminum dihydrogen phosphate in a volume ratio of 1:0.4:0.6, and its added amount is 4% of the total weight of the dry powder.

[0047] (2) Preparation method

[0048] Grind each dry powder first, pass through a 325-mesh sieve, take the sieve, weigh it according to the weight ratio, and put it into the mixer together with the solid composite binder to mix, add an appropriate amount of water to stir, stir evenly, and then add li...

Embodiment 3

[0053] Embodiment 3 selection test of binding agent

[0054] 1. Selection of binder

[0055] The method is the same as that of Example 1, and only the type of binding agent is changed for implementation. The results are shown in Table 1. In the blank test, the steel billet was directly put into the heating furnace for heat treatment without spraying paint, and the results are shown in Table 1.

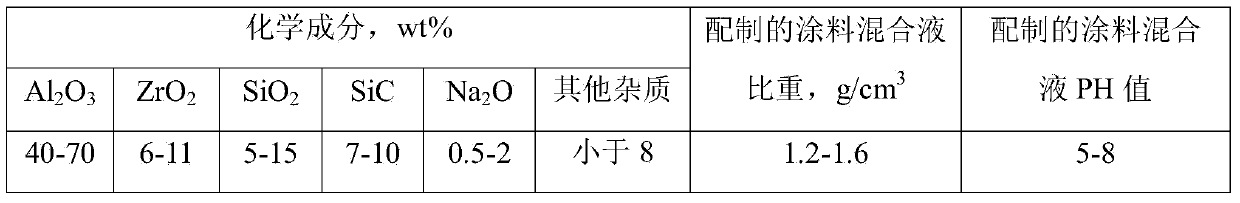

[0056] Table 1 Effects of binders on the effect of high-temperature protective coatings for high-carbon steel slabs.

[0057]

[0058] 2. Screening of the composite ratio of each component in solid and liquid composite binders

[0059] The method is the same as in Example 1, except that the composite ratio of each component in the solid and liquid composite binder is changed, and the blank test is that the steel billet is not sprayed with paint, and directly enters the heating furnace for heat treatment. The results are shown in Table 2.

[0060] Table 2 The effect of the composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com