Carbon/carbon composite material modified by silicon carbide and hydroxyapatite gradient coating and preparation method thereof

A technology of carbon composite materials and hydroxyapatite, which is applied in the preparation of SiC-HA gradient coating modified carbon/carbon composite materials, in the fields of biological bone replacement and bone grafting, can solve the problems of thermal expansion coefficient mismatch of coatings, etc. Achieve the effects of reducing defects, improving bonding strength and corrosion resistance, and relieving thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

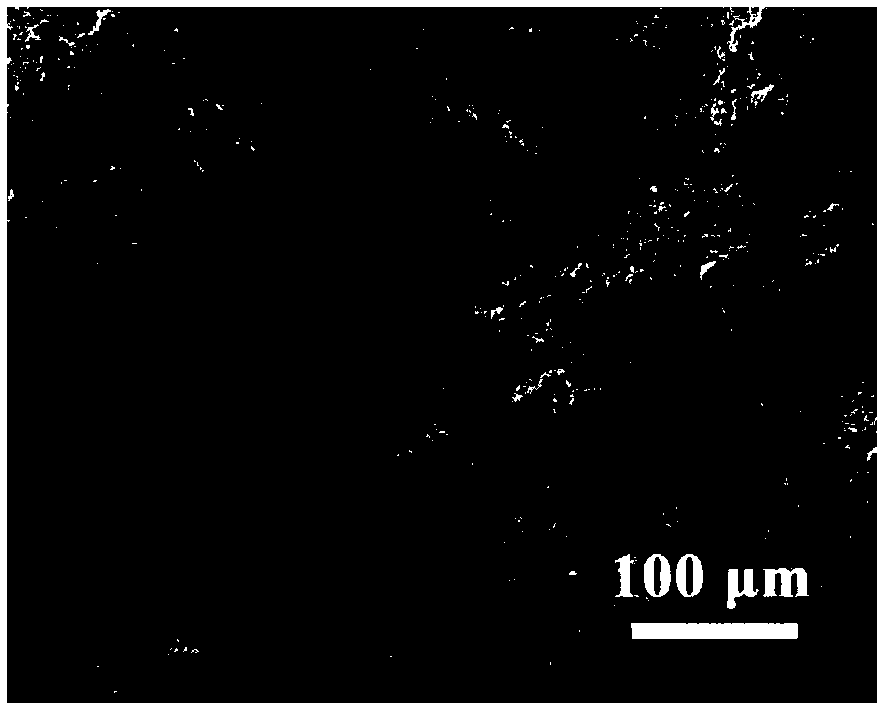

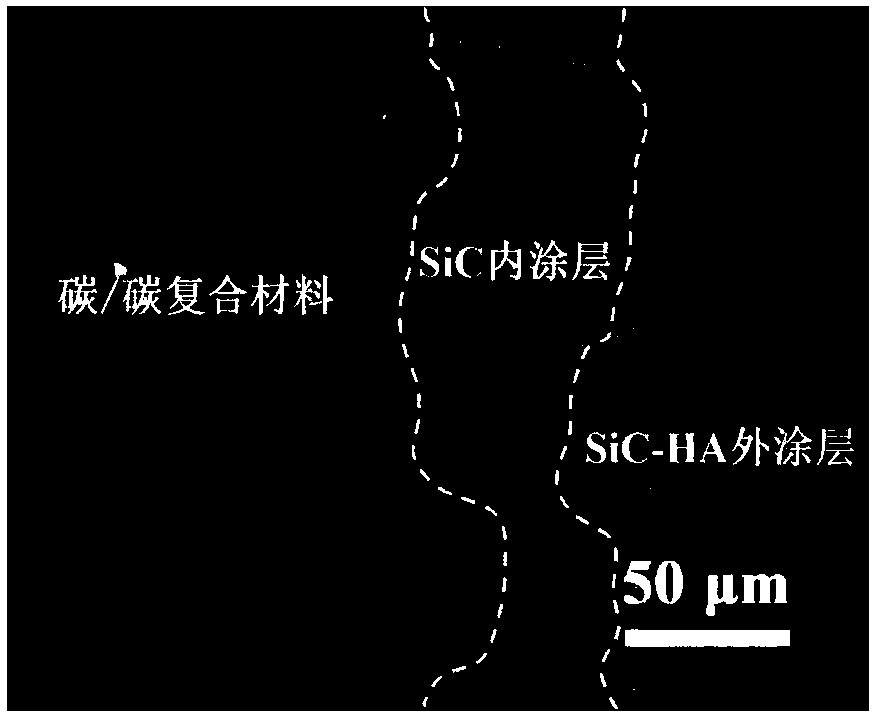

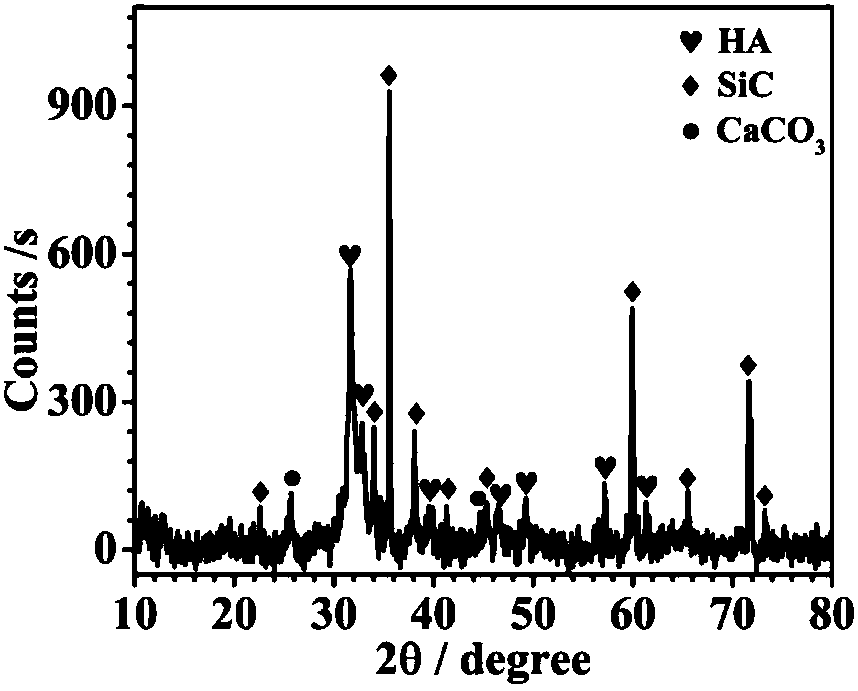

Image

Examples

preparation example Construction

[0027] Step 2, preparation of SiC inner coating: Si powder with a mass fraction of 75% to 80%, C powder with 10% to 15%, and Al with 5% to 10% 2 o 3 The powder is mixed evenly with a ball mill, and then put into an oven for drying. Put the mixed powder and the carbon / carbon composite material obtained in step 1 evenly in a graphite crucible, cover the graphite cover and put it in a high-temperature furnace, treat it at 1900-2200°C for 1-3 hours, and cool with the furnace. The SiC inner coating can be prepared on the surface of the carbon / carbon composite material.

[0028] Step 3. Prepare the SiC-HA outer coating: Put the SiC powder with a mass fraction of 20% to 80% and the HA powder with a mass fraction of 20% to 80% into a ball mill and mix them together evenly and dry them. The granulator performs granulation on the mixed powder after ball milling. Place the sample obtained in step 2 under the supersonic plasma spraying equipment, set the spraying power to 25kW~55kW, th...

Embodiment approach 1

[0030] 1) Cut the carbon / carbon composite matrix (with a density of 1.40-1.78g / cm 3 ) Wash with acetone, alcohol and deionized water for 20-30 minutes in sequence until the carbon particles are cleaned, and then put the cleaned carbon / carbon composite material sample in an oven at 50-70°C to dry for 10-15 hours for later use .

[0031] 2) The preparation method of SiC inner coating: weigh the Si powder material that mass fraction is 77%, the C powder material of 15%, the Al of 8% 2 o 3Put the powder into the ball mill jar, mix the three kinds of powder evenly, dry, then put the mixed powder and the cleaned carbon / carbon composite material into the graphite dry pot, seal it with the crucible cover and put it in the high temperature After heat treatment at 1900°C (protective atmosphere: argon) in the furnace for 2 hours, the SiC inner coating can be obtained on the carbon / carbon composite material.

Embodiment approach 2

[0033] 1) Cut the carbon / carbon composite matrix (with a density of 1.40-1.78g / cm 3 ) Wash with acetone, alcohol and deionized water for 20-30 minutes in sequence until the carbon particles are cleaned, and then put the cleaned carbon / carbon composite material sample in an oven at 50-70°C to dry for 10-15 hours for later use .

[0034] 2) The preparation method of SiC inner coating: weigh the Si powder material that mass fraction is 77%, the C powder material of 15%, the Al of 8% 2 o 3 Put the powder into the ball mill jar, mix the three kinds of powder evenly, dry, then put the mixed powder and the cleaned carbon / carbon composite material into the graphite dry pot, seal it with the crucible cover and put it in the high temperature After heat treatment at 2000°C (protective atmosphere: argon) in the furnace for 2 hours, the SiC inner coating can be obtained on the carbon / carbon composite material.

[0035] 3) The preparation method of the SiC-HA outer coating: weigh SiC pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com