Active HA coating prepared by compounding laser cladding and cold spraying and preparation method of active HA coating

A laser cladding and cold spraying technology, applied in the field of medical materials, can solve the problems of weak bonding strength and poor biocompatibility of HA coating, and achieve poor bonding ability, good biocompatibility, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

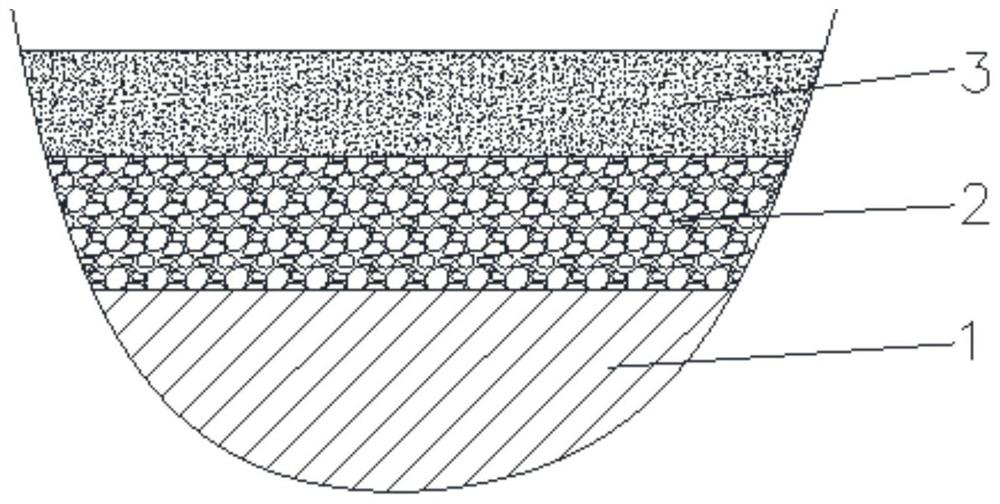

[0039] Such as figure 1 As shown, a preparation method of laser cladding and cold spraying combined to prepare active HA coating, mixing Cu metal powder and Ti-6Al-4V alloy powder into the first mixed powder, wherein the content of Cu metal powder is in the range of 10.0wt %~15.0wt%, the content range of Ti-6Al-4V alloy powder is 85.0wt%~90.0wt%, the main elements and mass percentage range of Ti-6Al-4V alloy powder are as follows: 5.50%~6.80%Al, 3.40% ~4.50% V, 0.25%~0.30% Fe, 0.05%~0.10% C, the balance is Ti, the first mixed powder is used as the laser cladding material of fusion layer 2; Cu metal powder and Ca(HPO 4 ) 2 ·H 2 O powder is mixed into the second mixed powder, wherein, Cu metal powder content ranges from 5.0wt% to 10.0wt%, Ca (HPO 4 ) 2 ·H 2 O powder content ranges from 90.0wt% to 95.0wt%, Ca(HPO 4 ) 2 ·H 2 The main elements and mass percentage ranges of O powder are as follows: 88wt% ~ 94wt% Ca (HPO 4 ) 2 ·H 2 O, 6.8wt% ~ 7.2wt% H 3 ·PO 4 , 0.03wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com