Gradient medical material and preparation method thereof

A gradient and additive technology, which is applied in pharmaceutical formula, metal material coating process, electrolytic coating, etc., can solve problems such as unfavorable patient rehabilitation, achieve the effect of improving anti-bacterial infection ability, increasing bonding strength, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

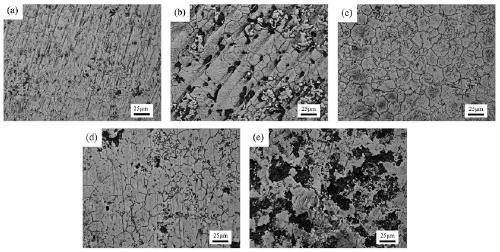

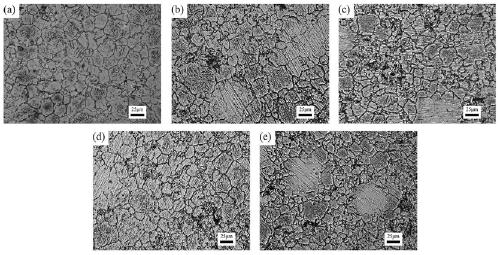

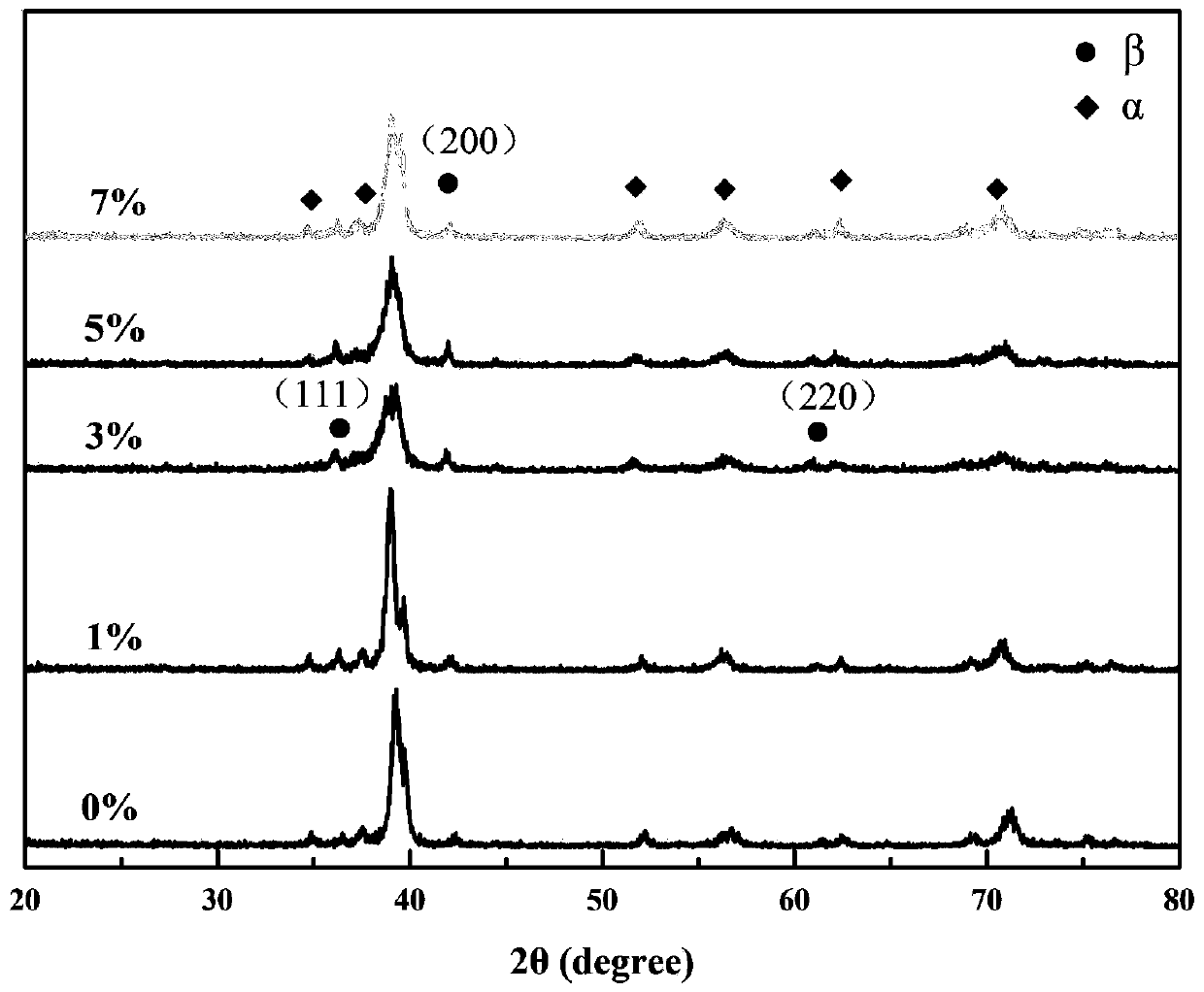

[0044] Embodiment 1: the addition of changing Zr element is: (a) 0wt%; (b) 1wt%; (c) 3wt%; (d) 5wt%; (e) 7wt%, determine optimal addition 3wt%, (b) 2wt%; (c) 4wt%; (d) 6wt%; (e) 8wt% to determine the optimum addition 6wt%. Finally, the addition amount of Cu and Zn elements in the change layer is (a) 0.2wt%; (b) 0.3wt%; (c) 0.4wt%, and the optimal addition amount is determined to be 0.4wt%.

[0045] A method for preparing a gradient medical material, characterized in that it comprises the following steps:

[0046] (1) Calculate the mass percentage of each element in the alloy, with TiH 2 , Mo powder, Nb powder, Zr powder and Ta powder as raw materials, according to the designed alloy composition ratio, accurately weigh the elemental metal powder of each element; put the weighed powder into a vacuum stainless steel tank, the ball-to-material ratio is 3:1 , and ball milled at a speed of 180r / min for 600min, ground the mixed material, and passed through a 400-mesh sieve;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com