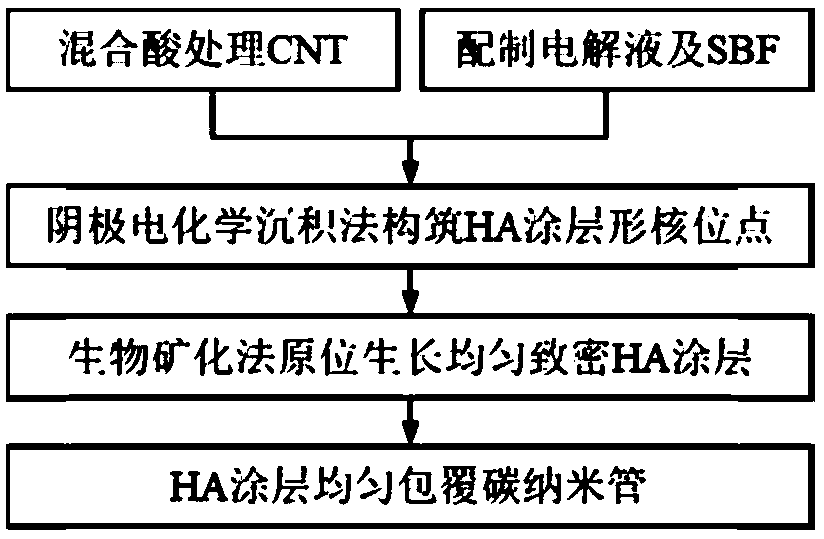

Method for preparing hydroxyapatite coating on surface of carbon nanotube based on electrochemical deposition method and biomineralization method in combined mode

A technology of hydroxyapatite and carbon nanotubes, which is applied in coatings, liquid chemical plating, plating of superimposed layers, etc., can solve the problems of difficult coating preparation, hydrophobicity, large length and diameter, and agglomeration , to achieve the effects of low production cost, controllable shape and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

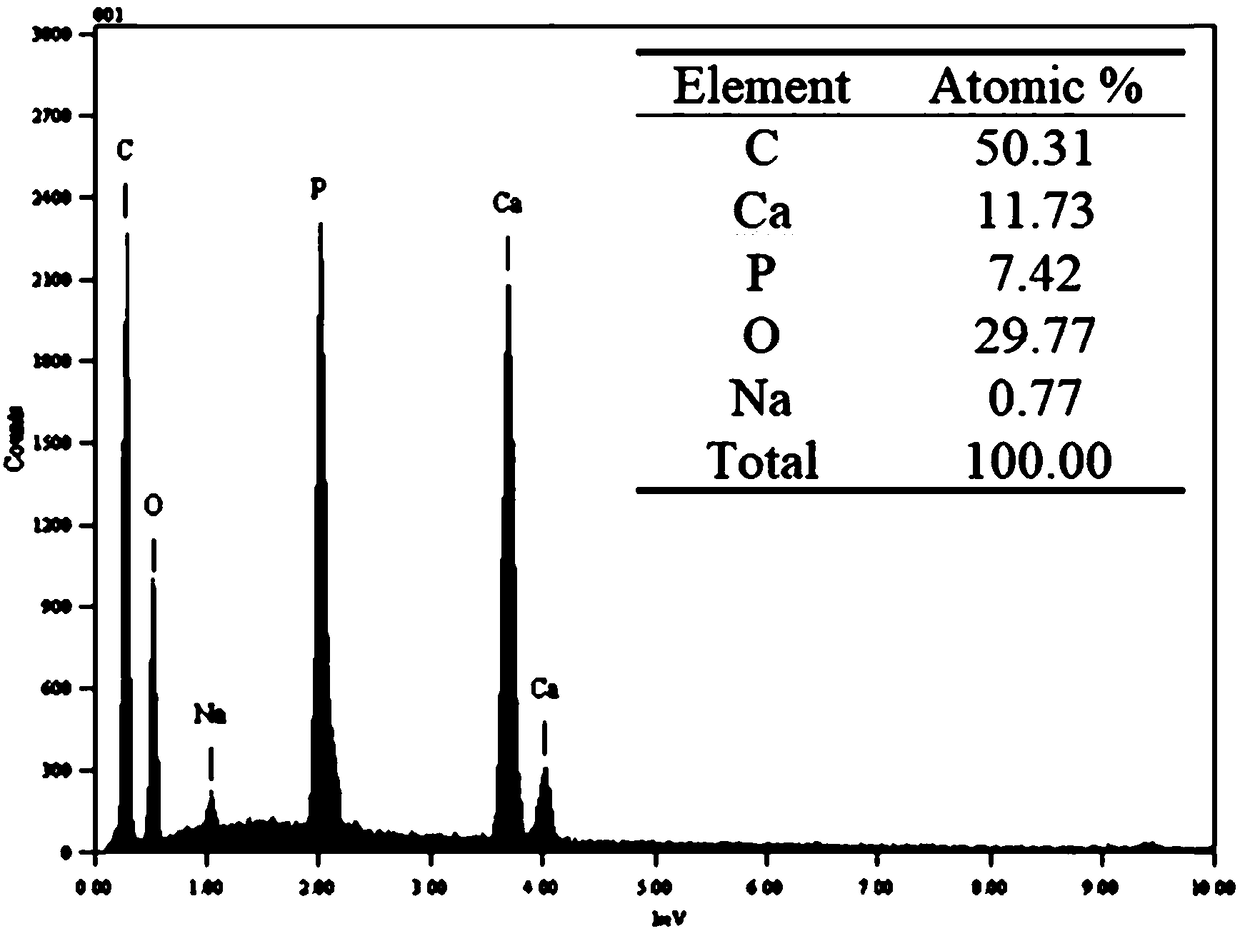

[0049] refer to figure 2 with image 3 A method for preparing a hydroxyapatite coating on the surface of a carbon nanotube based on an electrochemical deposition method and a composite biomineralization method of the present invention comprises the following steps:

[0050] Step 1: Clean and acidify the carbon nanotubes in sequence:

[0051] First, a certain amount of CNTs were washed in sequence with deionized water, absolute ethanol, and deionized water in an ultrasonic cleaner for 10 min each time. Then prepare concentrated H with a volume ratio of 3:1 2 SO 4 and concentrated HNO 3 Mix the solutions, put the cleaned CNTs into the prepared mixed acid solution, and treat them at a constant temperature at 60°C for 12 hours, take them out, wash them, and dry them for later use.

[0052] Step 2: Construct hydroxyapatite (HA, Ca 10 (PO 4 ) 6 (OH) 2 ) nucleation sites - small sized HA grains:

[0053] Conductive gel and flake graphite electrodes with acid-treated CNTs w...

Embodiment 2

[0059] refer to Figure 4 with Figure 5 A method for preparing a hydroxyapatite coating on the surface of a carbon nanotube based on an electrochemical deposition method and a composite biomineralization method of the present invention comprises the following steps:

[0060] Step 1: Clean and acidify the carbon nanotubes in sequence:

[0061] First, a certain amount of CNTs were washed in sequence with deionized water, absolute ethanol, and deionized water in an ultrasonic cleaner for 10 min each time. Then prepare concentrated H with a volume ratio of 3:1 2 SO 4 and concentrated HNO 3 Mix the solutions, put the cleaned CNTs into the prepared mixed acid solution, and treat them at a constant temperature at 60°C for 12 hours, take them out, wash them, and dry them for later use.

[0062] Step 2: Construct hydroxyapatite (HA, Ca 10 (PO 4 ) 6 (OH) 2 ) nucleation sites - small sized HA grains:

[0063] Conductive gel and flake graphite electrodes with acid-treated CNTs ...

Embodiment 3

[0069] refer to Image 6 with Figure 7 A method for preparing a hydroxyapatite coating on the surface of a carbon nanotube based on an electrochemical deposition method and a composite biomineralization method of the present invention comprises the following steps:

[0070] Step 1: Clean and acidify the carbon nanotubes in sequence:

[0071] First, a certain amount of CNTs were washed in sequence with deionized water, absolute ethanol, and deionized water in an ultrasonic cleaner for 10 min each time. Then prepare concentrated H with a volume ratio of 3:1 2 SO 4 and concentrated HNO 3 Mix the solutions, put the cleaned CNTs into the prepared mixed acid solution, and treat them at a constant temperature at 60°C for 12 hours, take them out, wash them, and dry them for later use.

[0072] Step 2: Construct hydroxyapatite (HA, Ca 10 (PO 4 ) 6 (OH) 2 ) nucleation sites - small sized HA grains:

[0073] Conductive gel and flake graphite electrodes with acid-treated CNTs w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com