Preparation method of three-phase CaP-glass coating/porous A1203 rack biological composite material

A composite material and glass coating technology, applied in coatings, medical science, prostheses, etc., can solve problems such as low bonding strength, poor dissolution rate and biological activity of sintered HA, and difficult replacement of hard tissues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Preparation of triple-phase glass: xCaO·(0.55-x)Na according to the composition formula 2 O 0.45P 2 o 5 , where x is 0.1, and P 2 o 5 , NaH 2 PO 4 and CaCO 3 , sintered at 1100°C for 1h to melt;

[0016] (2) quenching, grinding and sieving the molten glass obtained in step (1) successively to obtain glass powder with a particle size less than 20 μm;

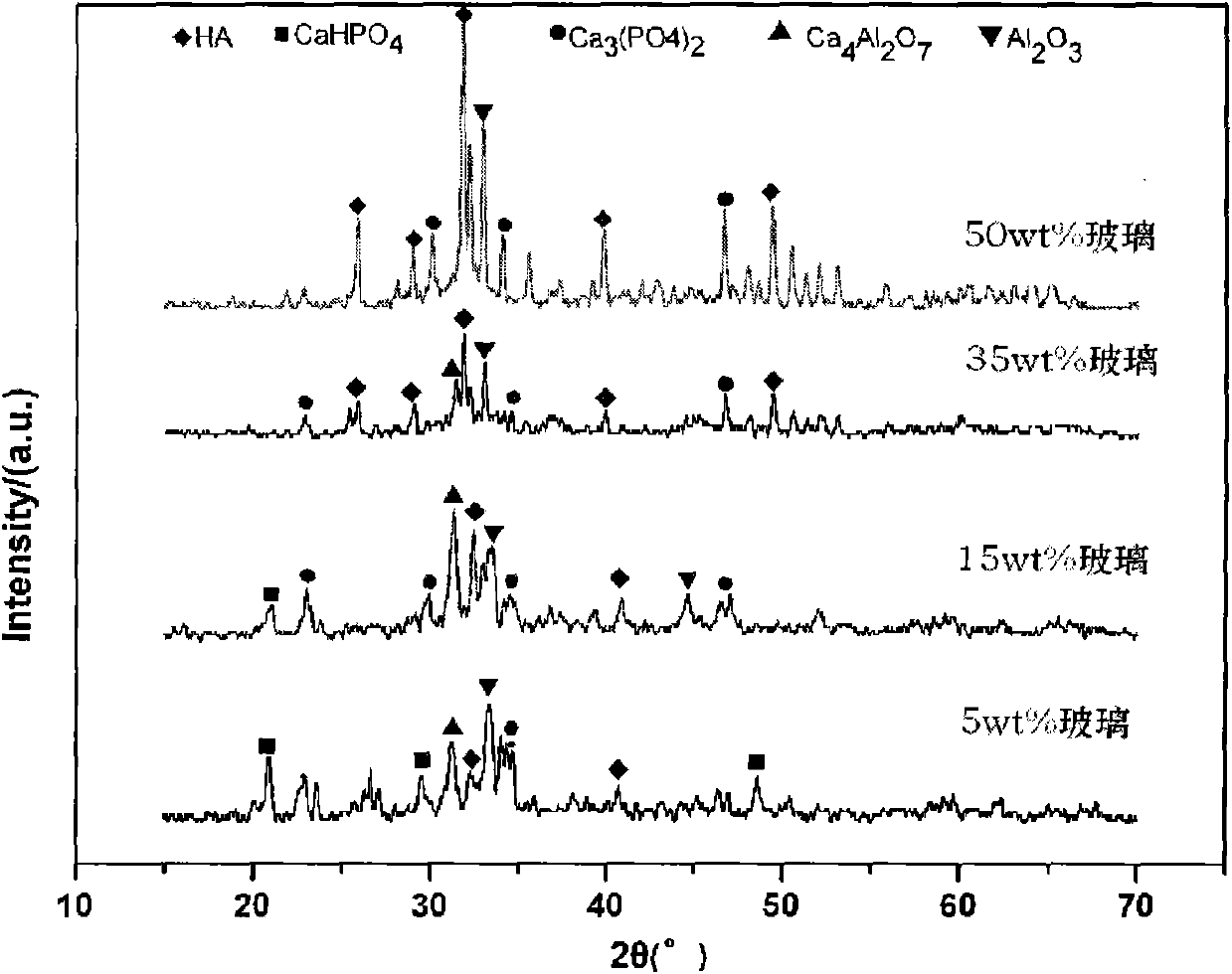

[0017] (3) The glass powder obtained in step (2) and hydroxyapatite (hydroxyapatite, HA) were mixed in ethanol, and ball milled for 24 hours to obtain a mixed slurry, wherein the glass powder accounted for the glass powder and hydroxyapatite 5% of the total mass of stone;

[0018] (4) Preparation of porous Al by impregnation method 2 o 3 scaffold, then in porous Al 2 o 3 The mixed slurry obtained in step (3) is coated on the support by a dip-rotation process, so as to obtain a composite coating;

[0019] (5) After the composite coating is dried, the porous Al 2 o 3 The scaffold was heated to 700°C at a r...

Embodiment 2

[0021] (1) Preparation of triple-phase glass: xCaO·(0.55-x)Na according to the composition formula 2 O 0.45P 2 o 5 , where x is 0.2, and P 2 o 5 , NaH 2 PO 4 and CaCO 3 , sintered at 1250°C for 1h to melt;

[0022] (2) quenching, grinding and sieving the molten glass obtained in step (1) successively to obtain glass powder with a particle size less than 20 μm;

[0023] (3) The glass powder obtained in step (2) and hydroxyapatite (hydroxyapatite, HA) were mixed in ethanol, and ball milled for 24 hours to obtain a mixed slurry, wherein the glass powder accounted for the glass powder and hydroxyapatite 50% of the total mass of stone;

[0024] (4) Preparation of porous Al by impregnation method 2 o 3 scaffold, then in porous Al 2 o 3 The mixed slurry obtained in step (3) is coated on the support by a dip-rotation process, so as to obtain a composite coating;

[0025] (5) After the composite coating is dried, the porous Al 2 o 3 The scaffold was heated to 700°C at a ...

Embodiment 3

[0027] (1) Preparation of triple-phase glass: xCaO·(0.55-x)Na according to the composition formula 2 O 0.45P 2 o 5 , where x is 0.3, and P 2 o 5 , NaH 2 PO 4 and CaCO 3 , sintered at 1150°C for 1h to melt;

[0028] (2) quenching, grinding and sieving the molten glass obtained in step (1) successively to obtain glass powder with a particle size less than 20 μm;

[0029] (3) The glass powder obtained in step (2) and hydroxyapatite (hydroxyapatite, HA) were mixed in ethanol, and ball milled for 24 hours to obtain a mixed slurry, wherein the glass powder accounted for the glass powder and hydroxyapatite 15% of the total mass of stone;

[0030] (4) Preparation of porous Al by impregnation method 2 o 3 scaffold, then in porous Al 2 o 3 The mixed slurry obtained in step (3) is coated on the support by a dip-rotation process, so as to obtain a composite coating;

[0031] (5) After the composite coating is dried, the porous Al 2 o 3 The scaffold was heated to 700°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com