HA (Hydroxyapatite) coating with high degree of crystallinity and nano-structure and preparation method of HA coating

A technology of hydroxyapatite and nanostructure, which is applied in coating, metal material coating technology, medical science, etc., can solve the problems of unsatisfactory osteogenesis and osseointegration performance, lack of osteogenic differentiation of induced stem cells, etc., to promote Adhesion of osteoblasts, improvement of osseointegration performance, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A. Preparation of plasma spray particles by sintering-crushing method

[0052] Take 200g of HA powder and 16g of PVA with a concentration of 10% and mix them evenly, then use the dry pressing method, pressurize 25MPa, and make a large piece with a diameter of 40mm, and calcinate and keep it at 1050°C for 5h, and get HA ceramic pieces after cooling in the furnace . Crushing the obtained ceramic sheet in a mortar, passing through 200-mesh and 400-mesh sieves to obtain particles with a particle size of 40-80 μm as a raw material for plasma spraying;

[0053] B. Preparation of HA coating by atmospheric plasma spraying

[0054] First, after the surface of the titanium alloy sheet (10mm×10mm×2mm) is sandblasted, it is ultrasonicated in an absolute ethanol solution for 10 minutes, rinsed with deionized water for 2-3 times, dried at 100°C, and set aside; then, Using the atmospheric plasma spraying process, the HA particles with a particle size of 40-80 μm described in A are s...

Embodiment 2

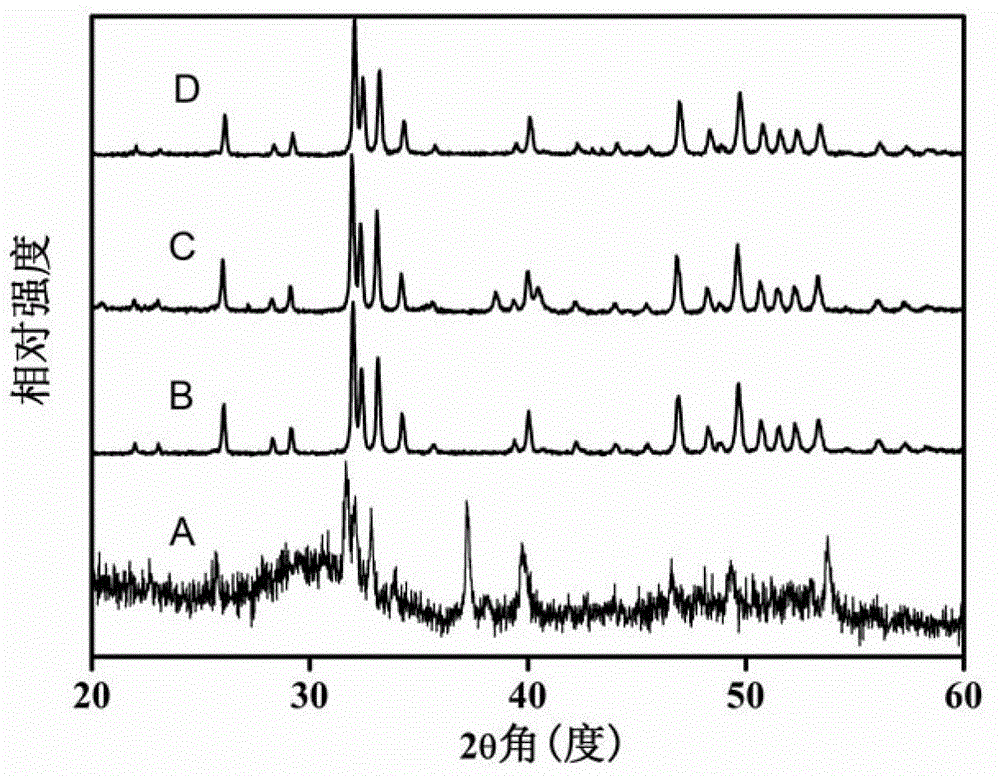

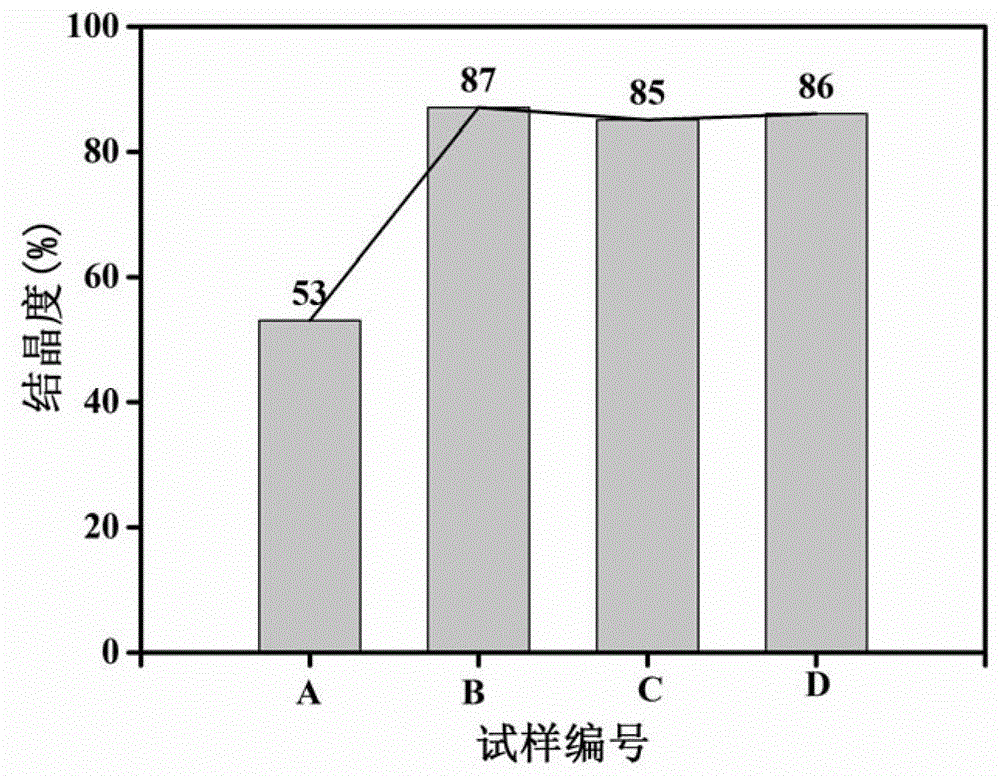

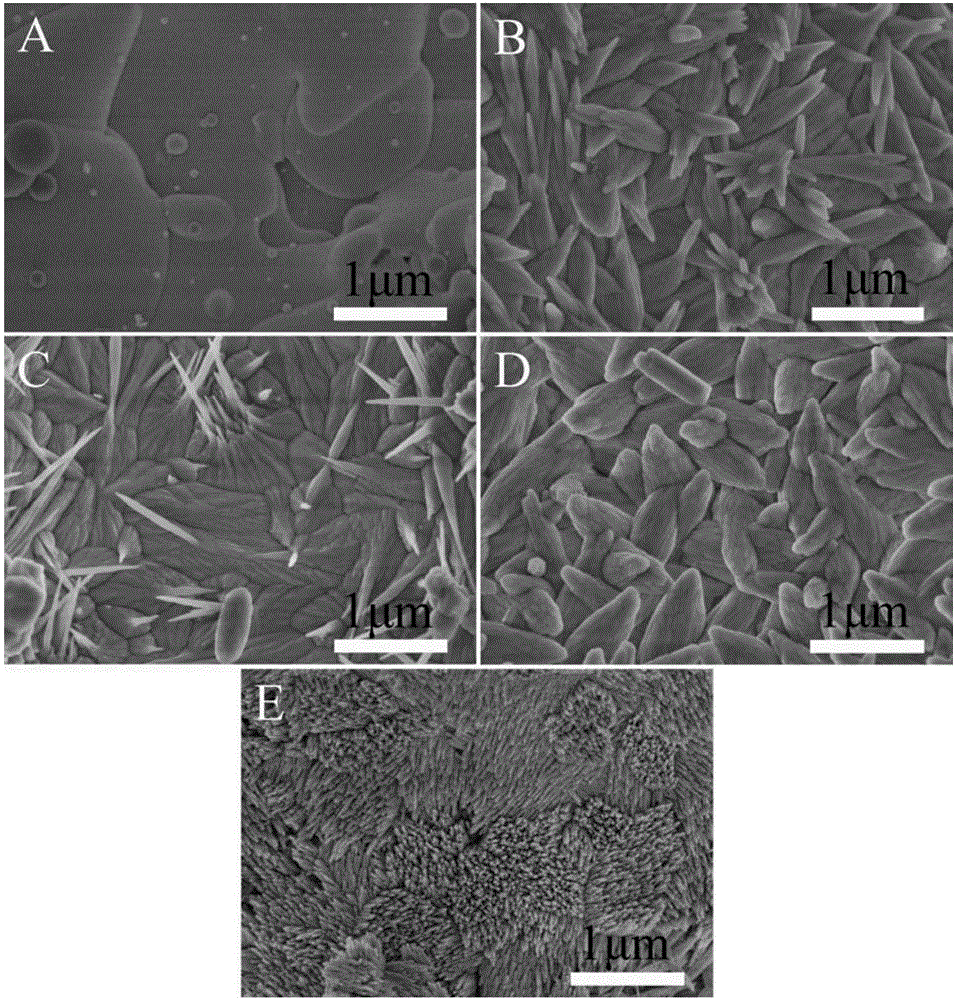

[0059] The HA coating prepared by atmospheric plasma spraying in Example 1 was hydrothermally heated at 180° C. for 24 hours in a pH=9 aqueous solution, and the specific hydrothermal treatment process was the same as in Example 1. The X-ray diffraction pattern confirms that the coating is a hydroxyapatite phase after hydrothermal treatment, and the amorphous phase is reduced (such as figure 1 shown in C); the calculated crystallinity (as figure 2 Shown in C) the results show that after hydrothermal treatment, the degree of crystallinity is increased from 53% to more than 85%, which is far higher than the requirement of not less than 62% for the degree of crystallinity in the medical device industry standard; scanning electron microscopy shows the surface morphology of the coating for disordered nanostructures (such as image 3 Shown in C); the results of degradability experiments show that hydrothermal treatment can improve its chemical stability. The experimental results o...

Embodiment 3

[0061] The HA coating prepared by atmospheric plasma spraying in Example 1 was hydrothermally heated at 180° C. for 24 hours in a pH=11 aqueous solution, and the specific hydrothermal treatment process was the same as that in Example 1. The X-ray diffraction pattern confirms that the coating is a hydroxyapatite phase after hydrothermal treatment, and the amorphous phase is reduced (such as figure 1 Shown in D); the calculated crystallinity (as figure 2 Shown in D) the result shows, after hydrothermal treatment, crystallinity is improved to more than 86% by 53%, is far higher than the requirement of crystallinity not less than 62% of medical device industry standard; Scanning electron microscope shows coating surface topography for disordered nanostructures (such as image 3 Shown in D); the results of degradability experiments show that hydrothermal treatment can improve its chemical stability. The experimental results of cells also show that the highly crystalline nanostru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com