Porous titanium cervical fusion cage with HA coating and preparation method of fusion cage

A fusion device and porous titanium technology, applied in the direction of coating, additive manufacturing, manufacturing tools, etc., can solve the problems of increased risk of trabecular fracture, slow integration speed, and unstable fixation, and achieve excellent early osseointegration effects, firmness and Connection method, effect of reducing the risk of arm breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

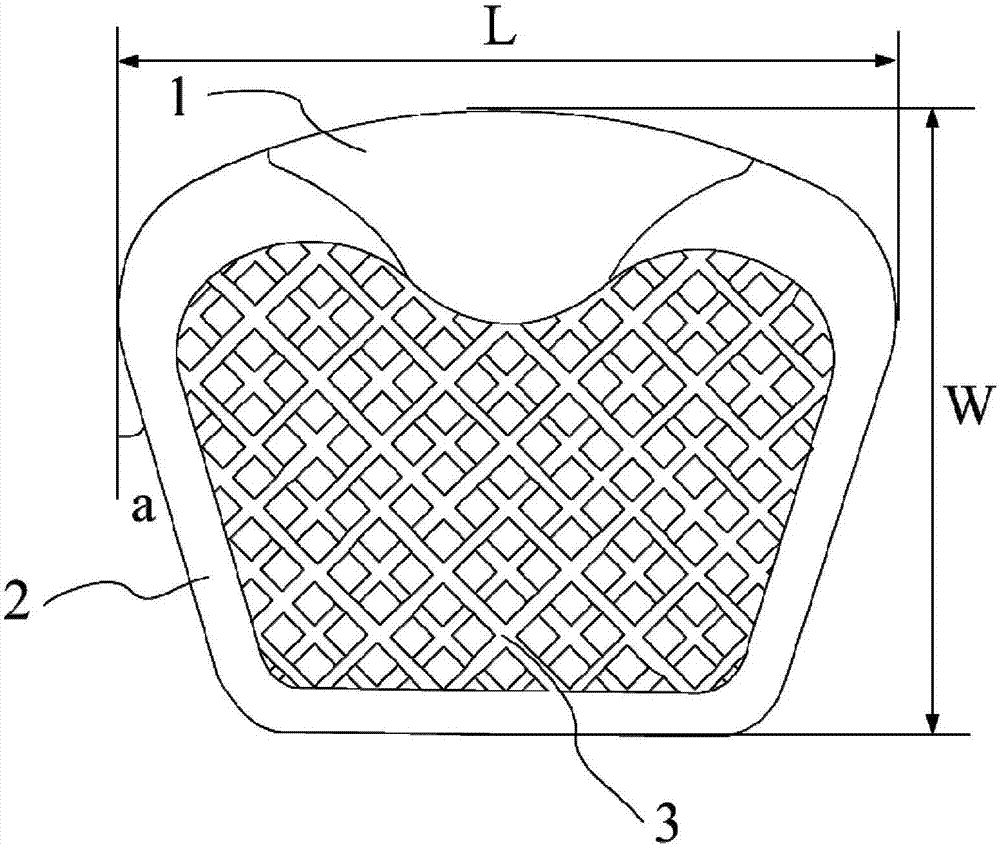

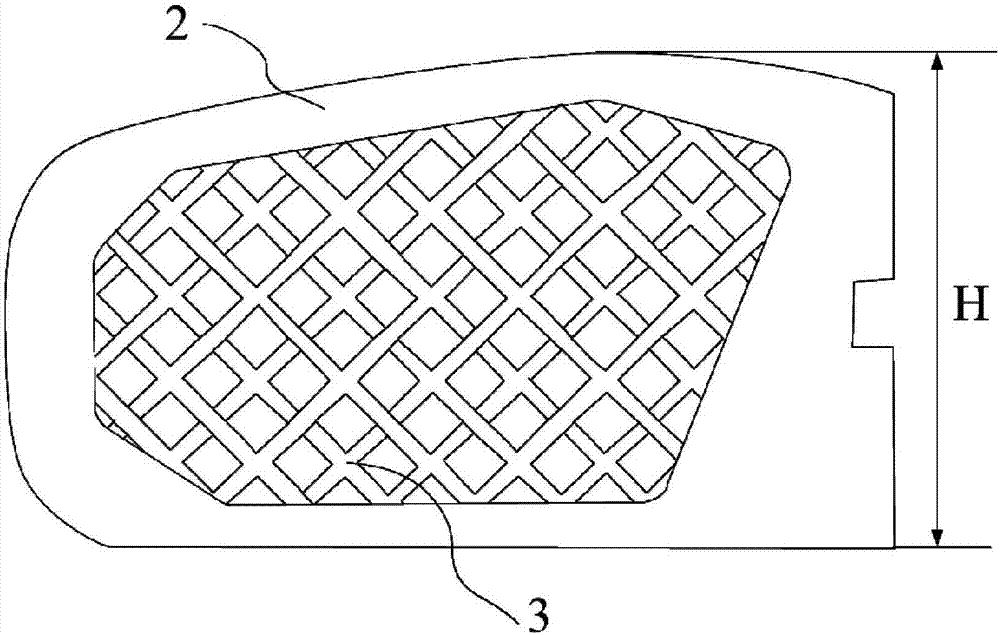

[0029] Such as figure 2 , image 3 The specifications of the wedge-shaped intervertebral fusion cage shown are: length (L): 13-16mm, width (W): 11-13mm, height (H): 5-8mm, wedge angle (angle shown in a): 17° .

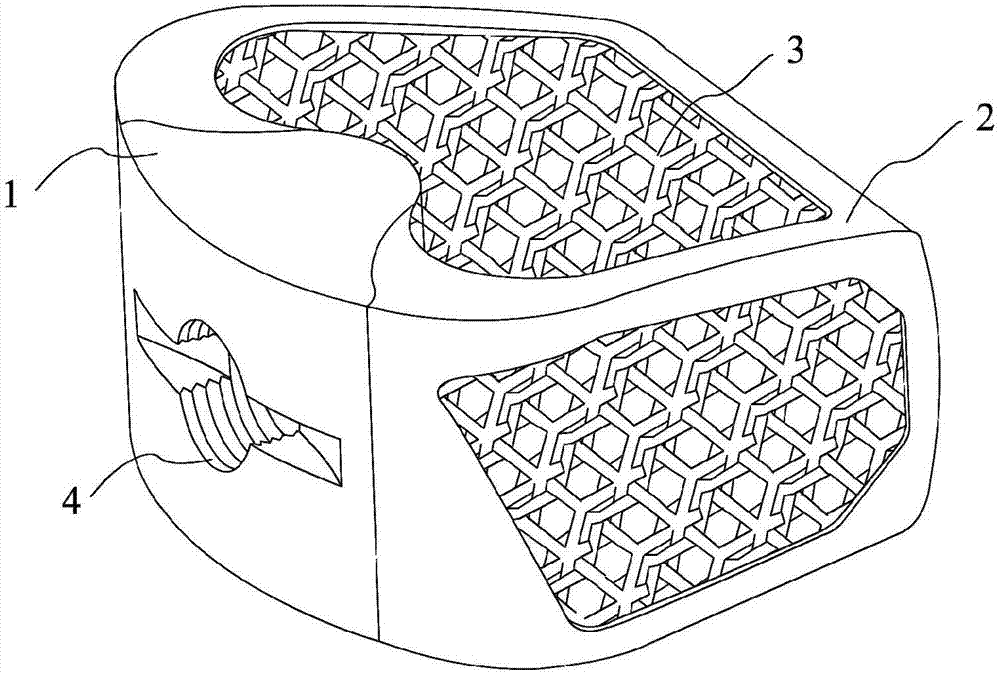

[0030] see Figure 1-4 , the present invention includes a circular arc-shaped solid titanium alloy structure 1 in the middle of the rear, a solid smooth titanium alloy thin-walled structure 2 similar to a bullet-shaped structure in the front, and a fusion device composed of a porous structure 3 filled therebetween. The center of the titanium alloy structure 1 is provided with a threaded groove 4 for connecting the fusion device to the implanted handle during the operation. The porous structure 3 is a regular 12-hedron porous structure with a porosity of 75%, a pore diameter of 400-800 microns, and a trabecular diameter of 300-400 microns. The tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Central thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com