Novel underwater pipeline leakage rapid repair construction method

An underwater pipeline and construction method technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of marine environment pollution, underwater pipeline leakage, caisson pipe perforation leakage, etc., and improve curing toughness. , The effect of promoting interfacial wetting and high bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the polyurethane prepolymer is as follows: slowly add diisocyanate with -NCO / -OH molar ratio of 2.2 to the dehydrated and dried castor oil while stirring, control the reaction temperature at 60-70°C, stir for 1 hour, and cool to prepare Obtain polyurethane prepolymer.

[0041] Polymer resin concrete is a concrete made of organic polymer materials and cement as a cementitious material. Usually, a certain amount of organic high molecular polymer is added while mixing the concrete, the hydration of the cement and the curing of the polymer are carried out at the same time, and they are filled with each other to form an overall structure, but there is no chemical reaction between the polymer and the cement. Compared with ordinary concrete, physical cement concrete has the characteristics of high tensile and flexural strength, fast curing, ductility, cohesiveness, impermeability, impact resistance and abrasion resistance.

[0042] Polymer resin conc...

Embodiment 1

[0055] A novel rapid repair construction method for underwater pipeline leakage, comprising the following steps:

[0056] (1) Leakage site location and base cleaning

[0057] After identifying the leaking part, use a high-pressure water gun to clean the leaking part and the surrounding area as a whole, remove surface debris, and clean the base of a certain area at the bottom of the leaking part of the pipeline;

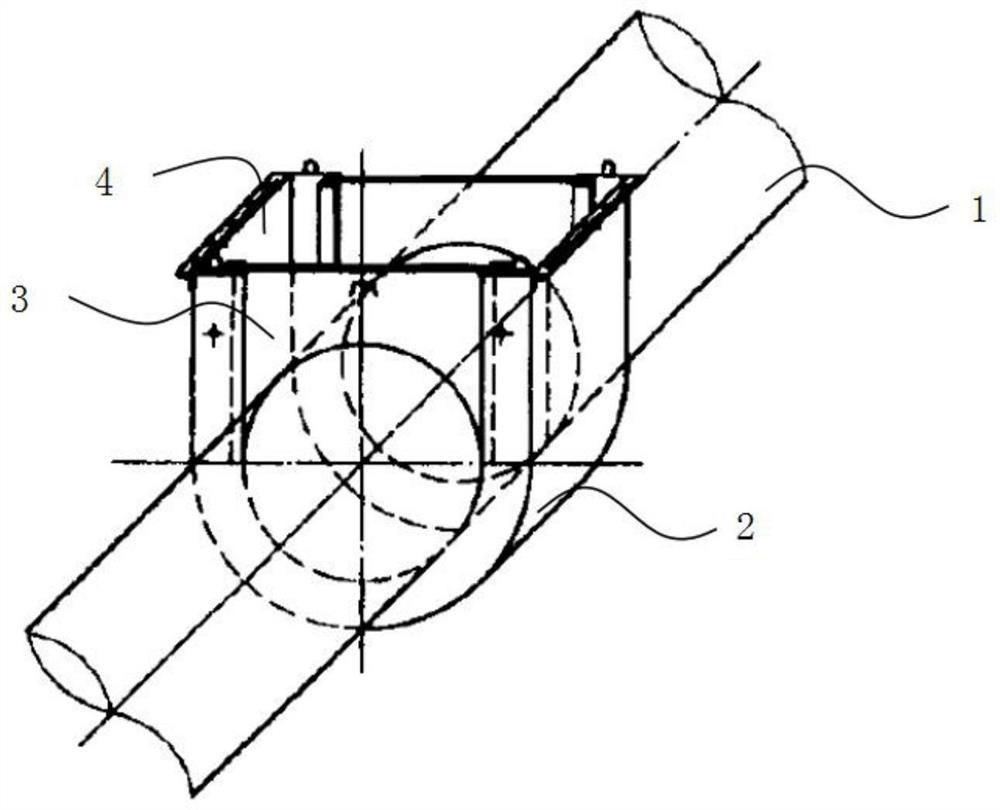

[0058] (2) Sheath installation

[0059] Install a U-shaped steel sheath in the area where the pipeline is to be poured. The top of the U-shaped steel sheath is provided with side panels, and the top is provided with a cover plate. After the installation is completed, the underwater pipeline and the U-shaped steel sheath A large number of rocks are thrown under the sleeve to make the underwater pipeline and U-shaped steel sheath in a stable and fixed state;

[0060] (3) Concrete mixing

[0061] According to the ratio, add the polymer resin matrix that has been stirr...

Embodiment 2

[0070] A novel rapid repair construction method for underwater pipeline leakage, comprising the following steps:

[0071] (1) Leakage site location and base cleaning

[0072] After identifying the leaking part, use a high-pressure water gun to clean the leaking part and the surrounding area as a whole, remove surface debris, and clean the base of a certain area at the bottom of the leaking part of the pipeline;

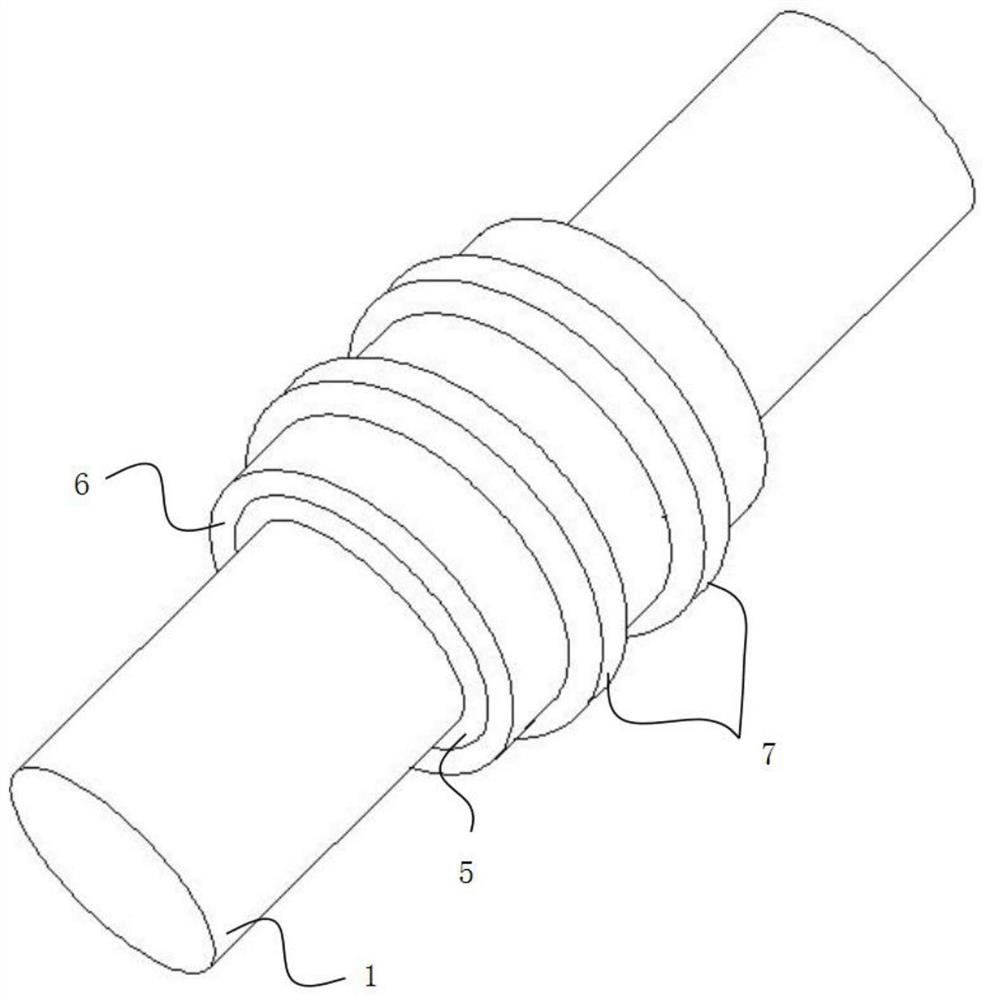

[0073] (2) Sheath installation

[0074] First, the area to be poured on the pipeline is covered with EPDM rubber layer and stainless steel coil layer in sequence, and after the outer circumference is fastened with hoops, a U-shaped steel sheath is installed. The U-shaped steel sheath There are side panels at the front and back of the top, and a cover at the top. After the installation is completed, a large number of rocks are thrown under the underwater pipeline and the U-shaped steel sheath, so that the underwater pipeline and the U-shaped steel sheath are stably fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com