Method for rapidly repairing metal crack damage with composite material

A composite material and metal technology, applied in the field of composite material adhesive repair, can solve the problems of low strength, average repair effect, high internal porosity of composite patch, etc., to achieve fast and convenient repair, low porosity, high mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

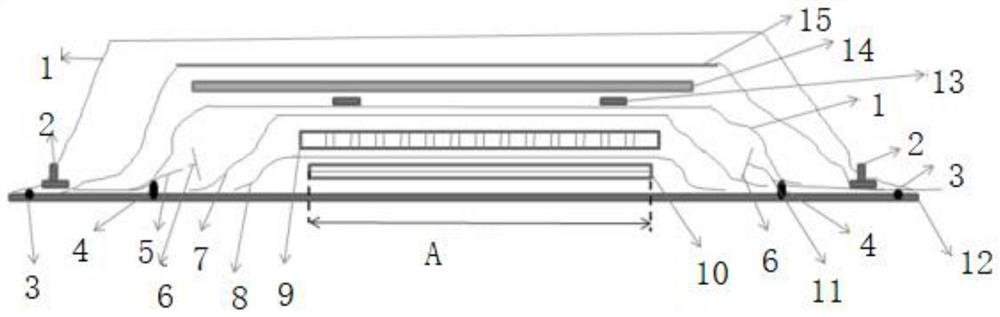

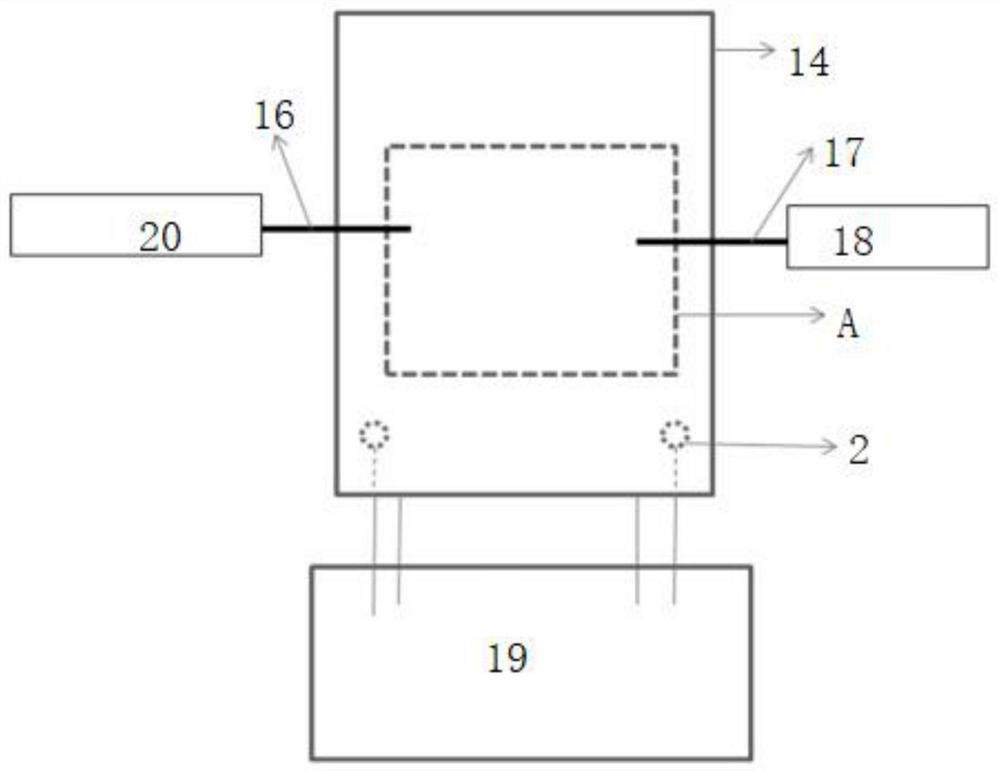

[0037] Such as figure 1 and figure 2 As shown, a method for quickly repairing metal crack damage with composite materials, wherein the metal crack length is 60mm, and the resin vacuum infusion method is used for repair. The repair resin is J-313 modified epoxy resin adhesive, and the resin viscosity is at room temperature. 800Cps, the CF3031 carbon fiber fabric used, the heat repair instrument used is HCS9200B, and the specific steps are as follows:

[0038] S1: Surface treatment: Use 120-mesh water sandpaper to polish the 200mm*200mm range of the damaged part, and then use 200-mesh water sandpaper to polish;

[0039] S2: laying reinforced fiber cloth: cut the fiber fabric into a size of 100mm*100mm, and lay 8 layers of fabric according to the laying angle required by the repair plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com