A kind of full bio-based two-component soybean adhesive, preparation method and application thereof

A soybean adhesive, a two-component technology, applied in the preparation of animal glue or gelatin, adhesives, non-polymer adhesive additives, etc., can solve the problem of not being able to take into account flame retardancy, water resistance, full bio-based practicability and environmental protection And other problems, to achieve the effect of improving the actual application performance, stable performance and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

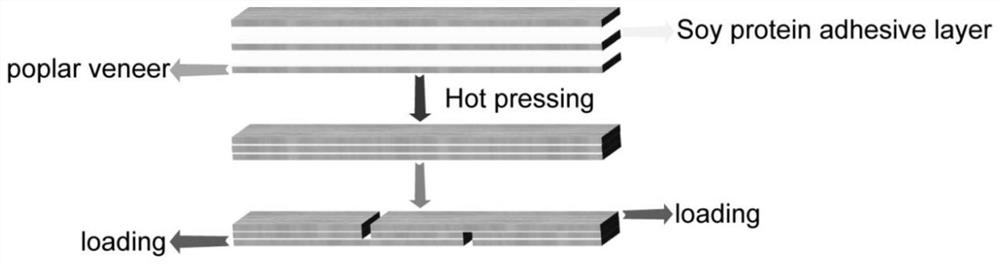

Method used

Image

Examples

Embodiment 1

[0064] In a 250mL beaker, add 22.2g of soybean protein isolate powder (protein weight percentage ≥ 90%), 65.3g of deionized water, stir and mix evenly, add 3.3g of sodium hydroxide (20wt% aqueous solution), adjust the pH to 10.5 , heated up to 60°C, reacted for 2 hours under 400r / min mechanical stirring, added phytic acid 5.5g (70wt% aqueous solution), and the measured pH value was 4.0 to obtain soybean protein mixed main ingredient A; then add soybean protein mixed main ingredient Add 3.7 g of cross-linking curing agent B furfuryl alcohol to A, and continue to stir for 15 minutes to obtain the target soybean protein adhesive, which is recorded as P4F16.7.

Embodiment 2

[0066] In a 250mL beaker, add 23.6g of soybean protein powder (protein weight percentage ≥ 90%), 65.0g of deionized water, stir and mix, add 3.2g of 20wt% sodium hydroxide solution, adjust the pH to 10.0, and heat up to 40 ℃, after reacting for 1 hour under mechanical stirring at 400r / min, add 7.0g of phytic acid (70wt% aqueous solution), the measured pH value is 3.5, and obtain soybean protein mixed main ingredient A; then add cross-linked soybean protein mixed main ingredient A The mixture B of furfuryl alcohol and furfural as the curing agent is 1.2g, wherein the mass ratio of furfuryl alcohol to furfural is 1:1, and the stirring is continued for 15 minutes to obtain the target soybean protein adhesive, which is marked as P3.5F5.

Embodiment 3

[0068] Add soybean protein powder 23.3g (protein weight percentage ≥ 90%), deionized water 64.0g in a 250mL beaker, after stirring and mixing, add 2.7g of 20wt% sodium hydroxide solution, adjust the pH to 9.5, and heat up to 70 ℃, after reacting for 3 hours under mechanical stirring at 400r / min, 7g of phytic acid (70wt% aqueous solution) was added, and the pH value was measured to be 3.0 to obtain soybean protein mixed main ingredient A; then 3g of bio-based crosslinking curing agent furfuryl alcohol, water 3g was stirred and mixed to obtain cross-linking curing agent B. Add 3g of cross-linking curing agent B to soybean protein mixing main agent A, and continue stirring for 15 minutes to obtain the target soybean protein adhesive, which was recorded as P3.5F10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com