Antimagnetic plasterboard applicable to high-humidity environments and preparation method thereof

A gypsum board and high-humidity technology, applied in the field of building materials, can solve the problems of damage to the beautification environment, loose gypsum board, damage to the shape, etc., and achieve the effect of good treatment effect, low cost and good shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

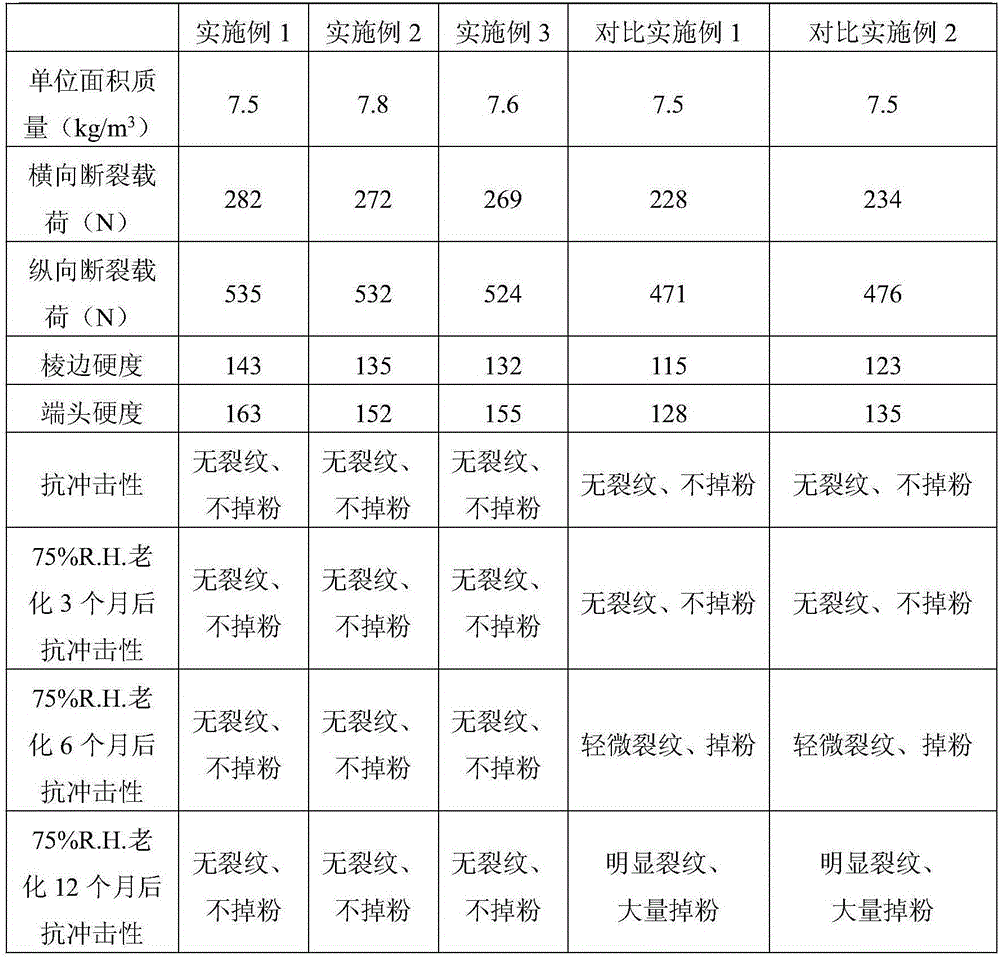

Examples

Embodiment 1

[0048] An antimagnetic gypsum board suitable for use in high humidity environments, comprising the following ingredients in weight percent:

[0049] Coir Shredded 12%

[0051] Foaming agent 0.3%

[0052] Gypsum clinker 25%

[0054] Wetting agent Hyonic PE-100 0.03%

[0055] Water 1.8%

[0056] Residue of causticizing white mud residue.

[0057] The moisture content of the causticizing white mud slag is 45-55%.

Embodiment 2

[0059] An antimagnetic gypsum board suitable for use in high humidity environments, comprising the following ingredients in weight percent:

[0060] Coir Shredded 8%

[0062] Foaming agent 0.5%

[0063] Gypsum clinker 20%

[0065] Wetting agent Hyonic PE-100 0.02%

[0066] water 3%

[0067] Residue of causticizing white mud residue.

[0068] The moisture content of the causticizing white mud slag is 45-55%.

Embodiment 3

[0070] An antimagnetic gypsum board suitable for use in high humidity environments, comprising the following ingredients in weight percent:

[0071] Coir Shredded 15%

[0073] Foaming agent 0.1%

[0074] Gypsum clinker 30%

[0076] Wetting agent Hyonic PE-100 0.05%

[0077] Water 0.5%

[0078] Residue of causticizing white mud residue.

[0079] The moisture content of the causticizing white mud slag is 45-55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com