FRP (fiber reinforced plastic) sectional material-concrete combined structure adopting novel combined interface

A combined structure and concrete technology, which is applied in the direction of building construction and construction, can solve problems such as limited connection/bonding ability, limited popularization and application, and corrosion of steel connectors, so as to achieve flexible layout of shear keys, avoid steel corrosion, The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

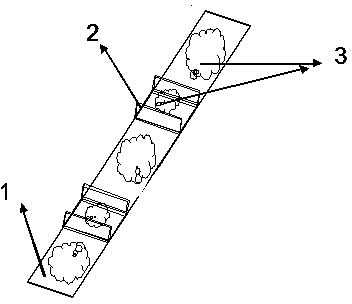

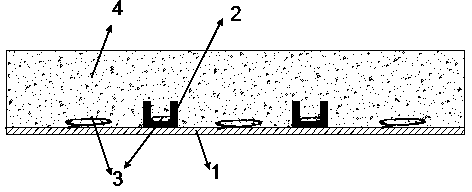

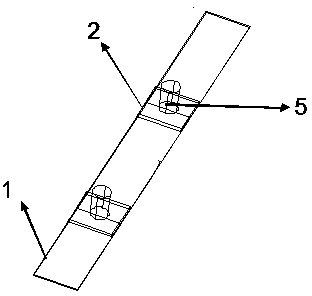

[0049] Such as figure 1 , figure 2 As shown, the FRP section bar-concrete composite structure provided by the present invention adopts the new combination interface, including FRP profile formwork 1, FRP shear force key 2, interface resin layer 3 and concrete 4; FRP shear force key 2 is arranged on the FRP profile formwork 1 surface; concrete 4 is poured directly on the surface of FRP profile formwork 1, which can save the traditional formwork required for traditional concrete pouring; FRP shear key 2, an interface resin layer is provided between the surface of FRP profile formwork 1 and concrete 4 3. The adhesive force is provided by the interface resin layer 3 .

[0050] The interface resin layer 3 is a wet bonding resin.

[0051] During specific construction, wet bonding resin must first be laid on the surface of the FRP profile formwork 1 including the surface of the shear bond 2, and the concrete 4 is poured on the surface of the FRP profile formwork 1 during the time...

Embodiment 2~3

[0082] In this example, the FRP profile-concrete beam structure is prepared by using the FRP profile-concrete composite structure of the new combination interface described in Example 1, and the specific situation is introduced as follows.

[0083] Example 2 and Example 3 FRP profile-concrete T-shaped composite beam specimens were prepared with the FRP profile-concrete composite structure of the new composite interface described in Example 1. The preparation method is the same as in Example 1, and the specific specifications of the prepared T-shaped composite beam test piece are: the length of the T-shaped composite beam beam is 3.2m, the clear span is 3.0m, and the tension zone at the bottom of the T-shaped beam is equipped with 2 20mm HRB335 grade steel bar. The size of the T-shaped section is 450mm×380mm×150 mm×80 mm (width of upper flange×height of section×width of web×thickness of upper flange). The FRP profile formwork of this embodiment is made by vacuum introduction ...

Embodiment 4~5

[0129] The main purpose of Examples 4-5 is to detect the fatigue performance of the FRP profile-concrete composite beam using the new composite interface and the fatigue performance of the new composite interface.

[0130] The specific specifications of the prepared FRP profile-concrete T-beam composite specimen are as follows: the beam length is 3.2 m, the clear span is 3.0 m; section height×web width×top flange thickness); there are 2 20mm HRB335 tension steel bar. The FRP profile-concrete T-beam composite specimen prepared in Examples 4 to 5 has the same cross-sectional form as in Examples 2 to 3, and the FRP profile formwork used is a U-shaped FRP profile. The difference between Example 4 and Example 5 The difference lies in the fiber layup at the bottom of the profile used by the two. The bottom of the FRP profile template is laid with unidirectional fiber cloth along the length of the beam, which mainly bears the tension. The fiber materials and layers laid on the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com