Grouting material, and preparation method and application thereof

A technology of grouting materials and raw materials, applied in the field of building materials, can solve the problems of low cross-linking degree, environmental pollution, low mechanical properties, etc., and achieve the effects of simple operation, energy saving, and flexible construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

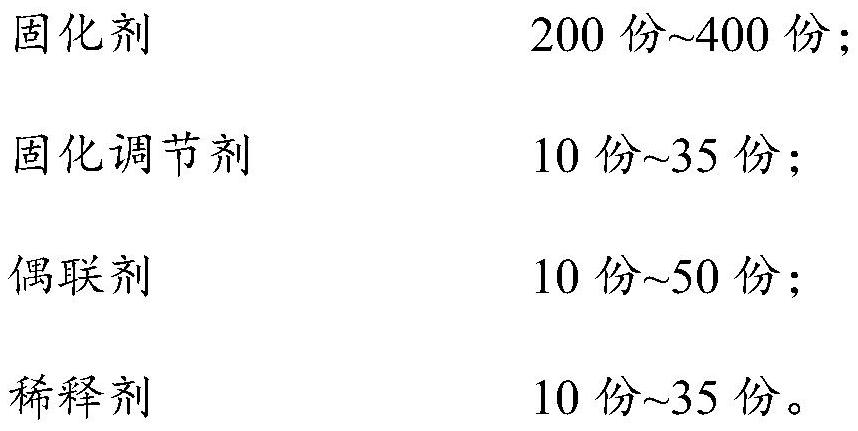

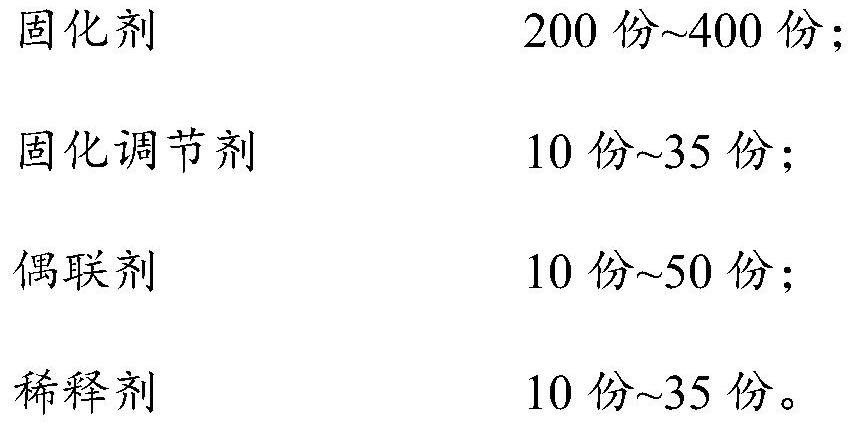

[0083] A kind of grouting material is prepared in this embodiment, and the specific raw material components are shown in Table 1, and the specific process is as follows:

[0084] S1. Heat the epoxy matrix at 60°C, then add reactive diluent and inorganic filler, and stir evenly at a speed of 250rpm to obtain component A;

[0085] S2. Mix all the raw materials of component B, and stir evenly at a speed of 300 rpm to obtain component B;

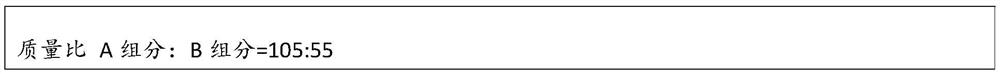

[0086] S3. Mix A component and B component according to the mass ratio to get the grouting material.

[0087] Examples 2-6 respectively prepared a grouting material, the difference from Example 1 is that the specific raw material components are different, and the specific components are shown in Tables 2-6.

[0088] Table 1 is in parts by mass, the raw material components used in Example 1

[0089]

[0090]

[0091] Table 2 is by mass parts, the raw material component used in embodiment 2

[0092]

[0093] Table 3 is by mass parts, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com