Preparation method of fluorine-doped precast rod

A technology for preforms and optical fiber preforms, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult preparation of fluorine-doped preforms, and achieve the effect of flexible design and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

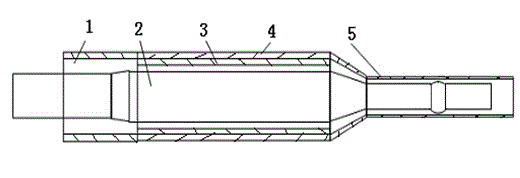

[0017] Embodiment 1: refer to figure 1 , the preparation method of the present embodiment comprises the following steps:

[0018] (1) Treat the fluorine-doped base tube with a ΔN of 0.28 and an outer diameter of 30mm and the large and small support tubes at both ends with acid water, clamp the fluorine-doped base tube 4 on the rear chuck of the MCVD glass lathe, and place the large and small support tubes respectively The support tube 1 and the small support tube 5 are clamped on the front chuck of the MCVD glass lathe, 2000ml / min oxygen is introduced into the reaction tube as a protective gas, the hydrogen-oxygen torch is ignited, and the fluorine-doped base tube and the large and small The support tubes are fused and sintered together.

[0019] (2) Gradually increase the temperature while feeding O 2 and SF 6 The gas enters the reaction tube, and the fluorine-doped substrate tube is subjected to high-temperature polishing five times, the lathe speed is 40rpm, the lamp spe...

Embodiment 2

[0031] Embodiment 2: refer to figure 1 , the preparation method of the present embodiment comprises the following steps:

[0032] (1) Treat the fluorine-doped substrate tube with a ΔN of 0.22 and an outer diameter of 20 mm and the large and small support tubes at both ends with acid water, clamp the fluorine-doped substrate tube on the rear chuck of the MCVD glass lathe, and place the large support tubes respectively The tube 1 and the small support tube 5 are clamped on the front chuck of the MCVD glass lathe, and 2000ml / min oxygen is introduced into the reaction tube as a protective gas, the hydrogen-oxygen torch is ignited, and the fluorine-doped base tube and the large and small support The tubes are fused and sintered together.

[0033] (2) Gradually increase the temperature while feeding O 2 and SF 6 The gas enters the reaction tube, and the fluorine-doped substrate tube is subjected to high-temperature polishing five times, the lathe speed is 35 rpm, the lamp speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com