Film covering device for constructing self-adhered coiled material with wet method

A technology of self-adhesive roll material and laminating device, which is applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc. The effect of improved bonding strength, low cost, and improved appearance of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

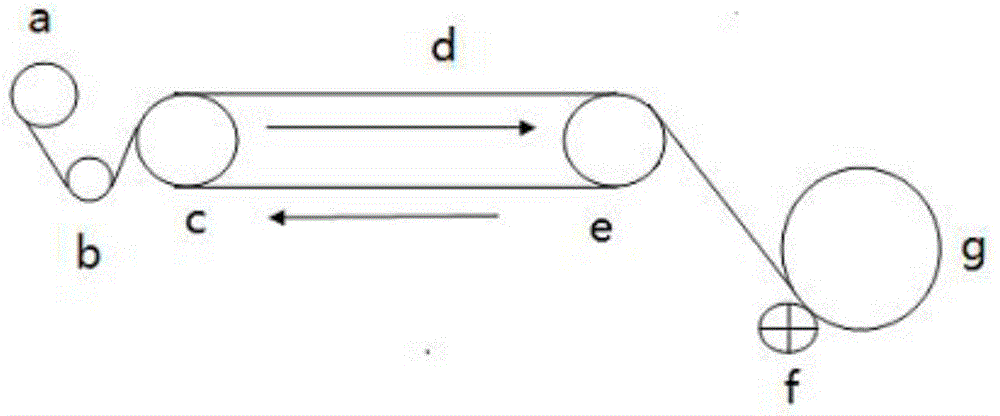

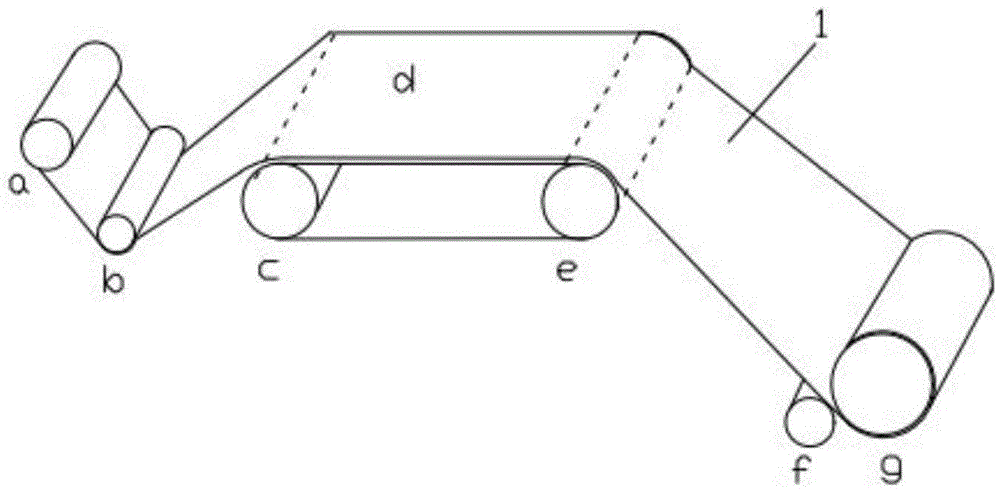

Method used

Image

Examples

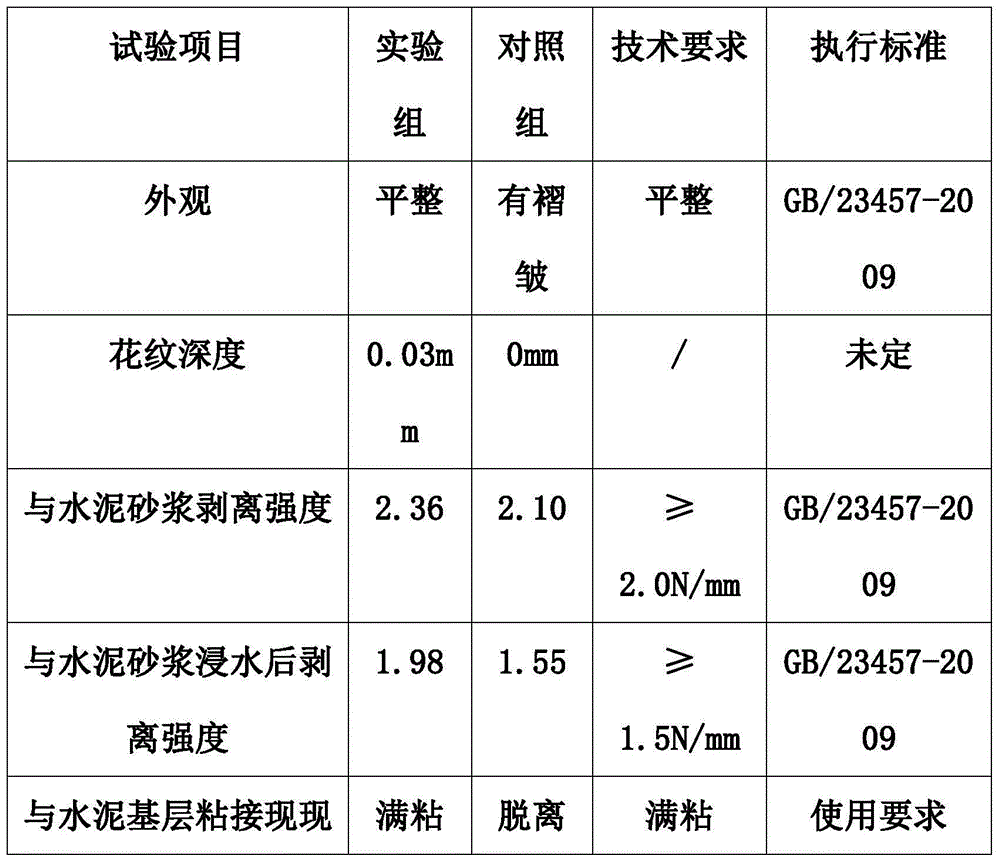

example 2

[0036] The device is applied to the production of wet-laid waterproof membranes to produce W (wet-laid) PY type I single-sided 3.0mm products in GB / T23457-2009 "Pre-laid / Wet-laid waterproof membranes". The coating process is as follows: 40g PE isolation film is used, the temperature of the chilled water for cooling the steel belt is 10°C, the temperature of the self-adhesive asphalt material is 145°C, the production speed is 40m / min, the surface temperature of the embossing roller is 120°C, and the isolation film is rolled flat Enter the cooling steel belt, contact with the self-adhesive asphalt material to cool down and initially form, the isolation film is conveyed with the cooling steel belt to the lower tangent point of the main driving roller, where the embossing roller squeezes the isolation film on the lower surface of the coil, and the film coating process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com