Preparation method and use method of cross-linked hyperbranched amine-modified oxidized starch adhesive for laminated wood

A technology for oxidizing starch and adhesives, applied in the direction of starch-derived adhesives, adhesive types, etc., can solve the problems of water resistance and low wet bonding strength of starch adhesives, and achieve improved corrosion resistance and wide application And development prospects, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

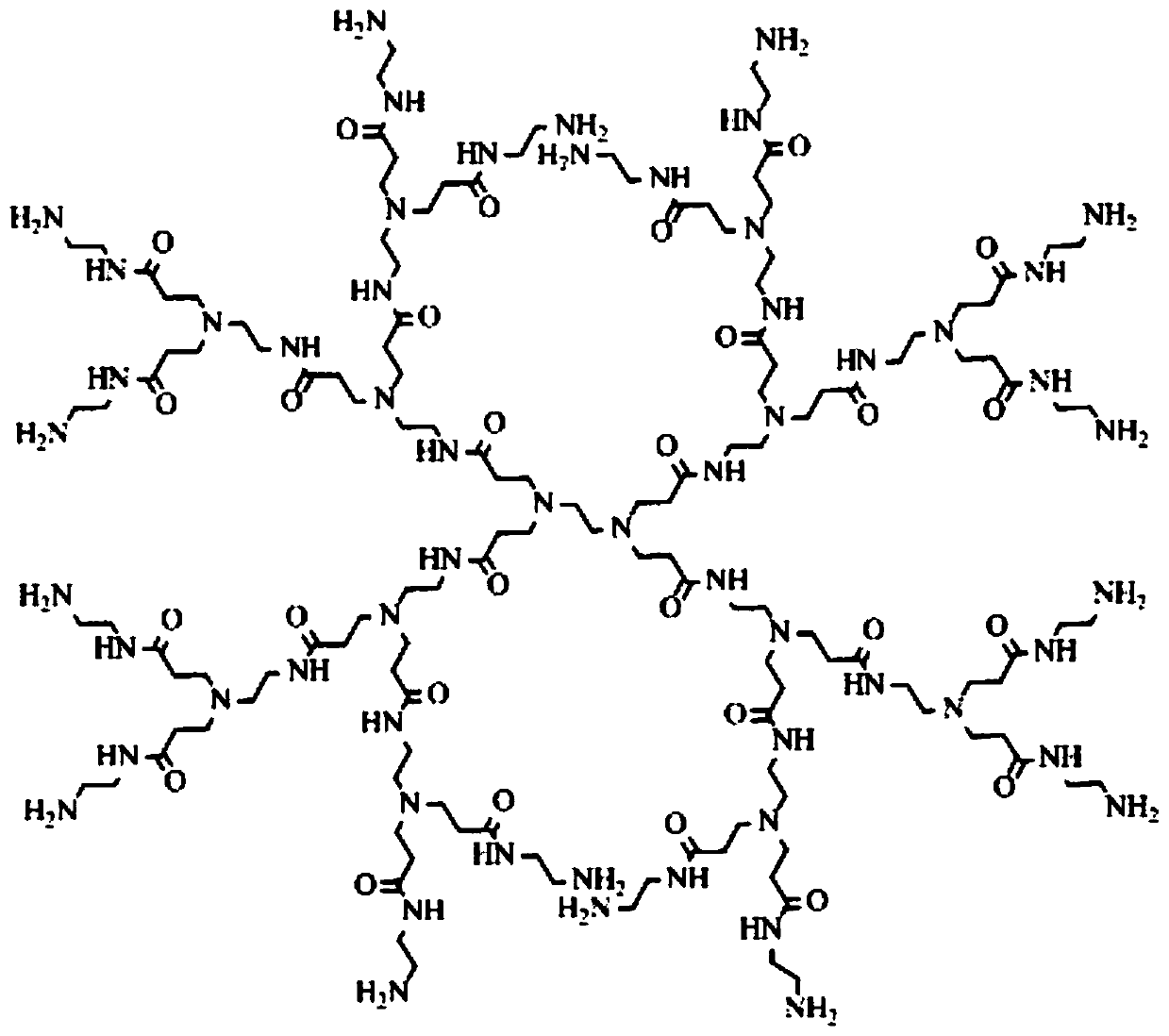

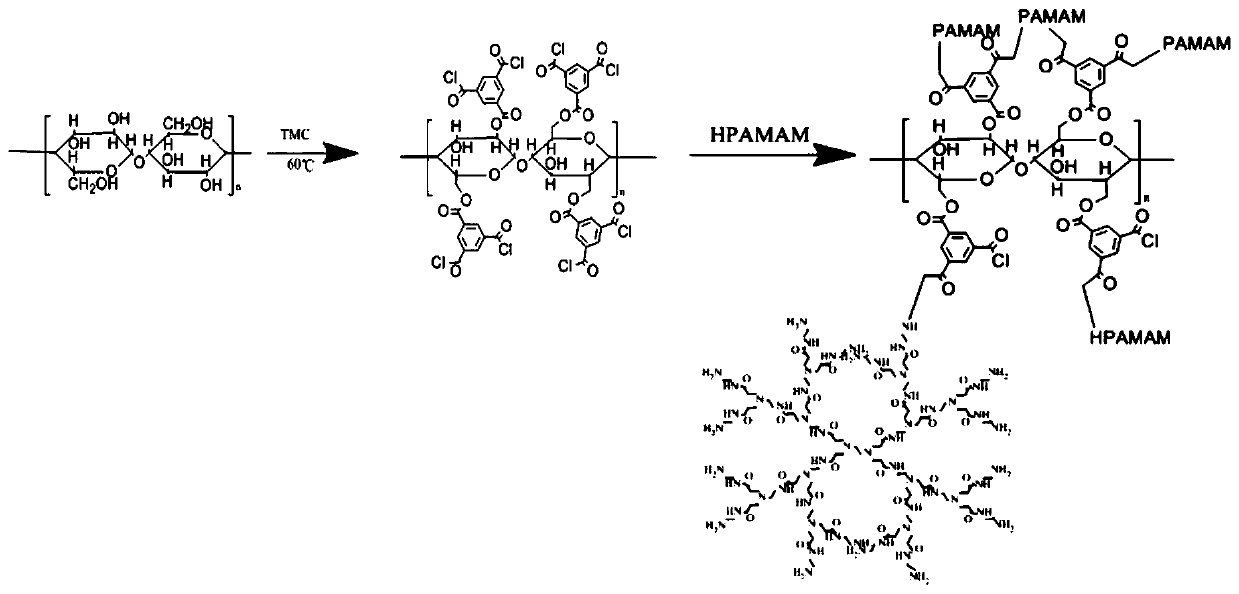

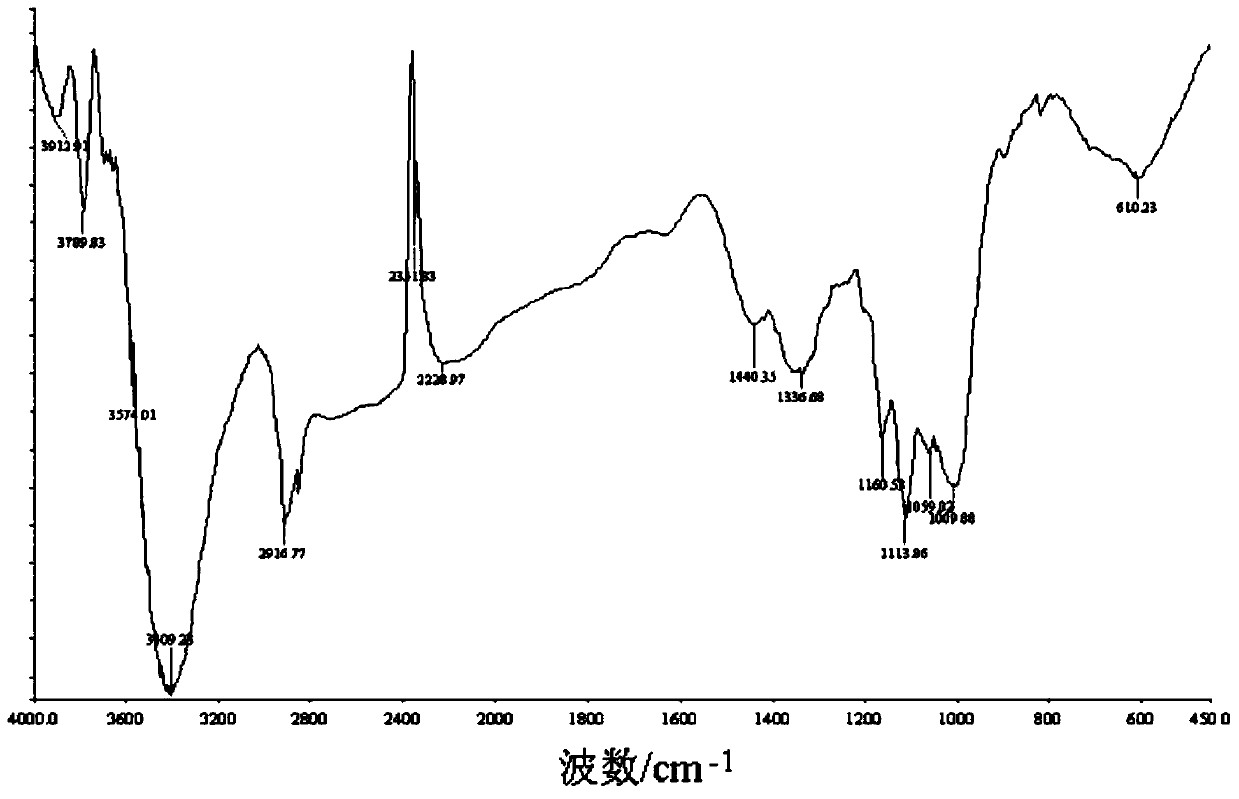

[0029] Embodiment 1: This embodiment is a method for preparing a cross-linked hyperbranched amine-modified oxidized starch adhesive applied to glued wood. The specific process is as follows:

[0030] 1. Preparation of oxidized starch adhesive: Add cornstarch and distilled water into a four-necked flask, and the four ports of the four-necked flask are respectively connected to a stirring device, a thermometer, a spherical condenser tube and a rubber stopper; the cornstarch and distilled water are stirred evenly and then added Ammonium sulfate, then put it in a water bath at 60°C to 65°C and keep it warm for 2h to 2.5h, then raise the temperature of the water bath to 90°C to 95°C and gelatinize at 90°C to 95°C for 0.5h to 1h to adjust the pH value of the product 7.8-8.2, naturally cooled to room temperature to prepare oxidized starch adhesive;

[0031] The mass ratio of described cornstarch and distilled water is 1:(5.5~6);

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pH value of the product is adjusted in step 1 by adding sodium hydroxide aqueous solution or hydrochloric acid. Others are the same as the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the organic polar solvent described in step three is dimethyl sulfoxide, N,N-dimethylformamide and N,N- One or more mixtures of dimethylacetamide. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com