Patents

Literature

61results about How to "Optimize the construction method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

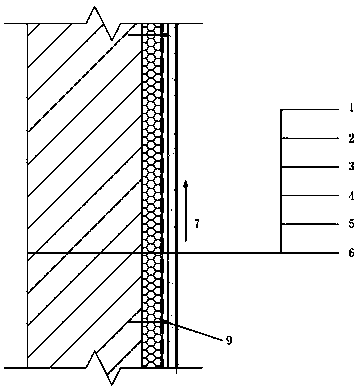

Non-pressed pipeline reinforcing structure for road surface and construction method for non-pressed pipeline reinforcing structure

InactiveCN105155376ANot affectedPrevent penetration corrosionPipe laying and repairRoadwaysArchitectural engineeringStructural engineering

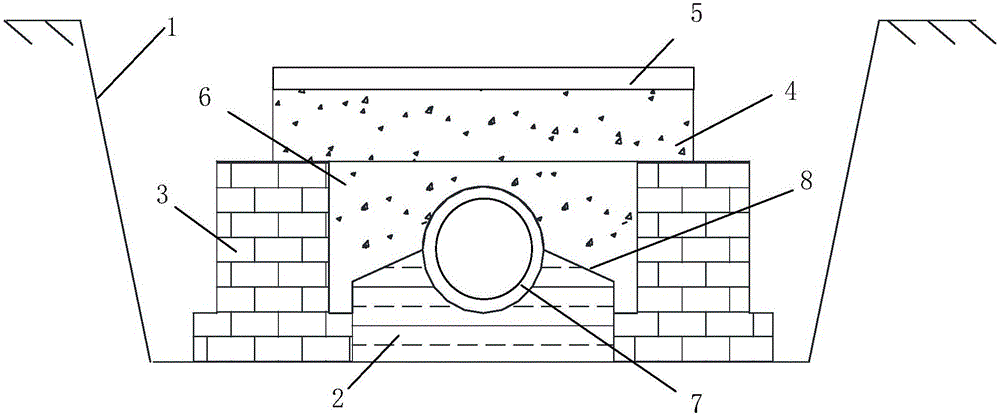

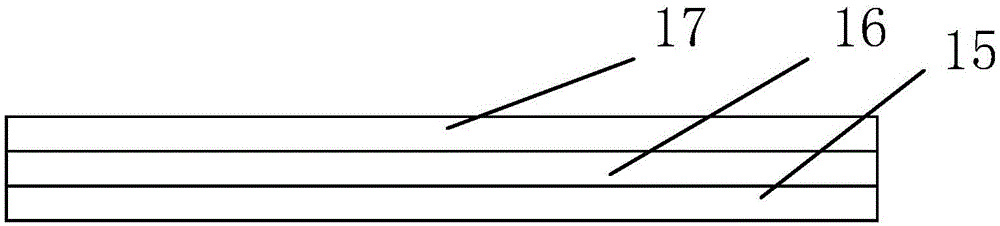

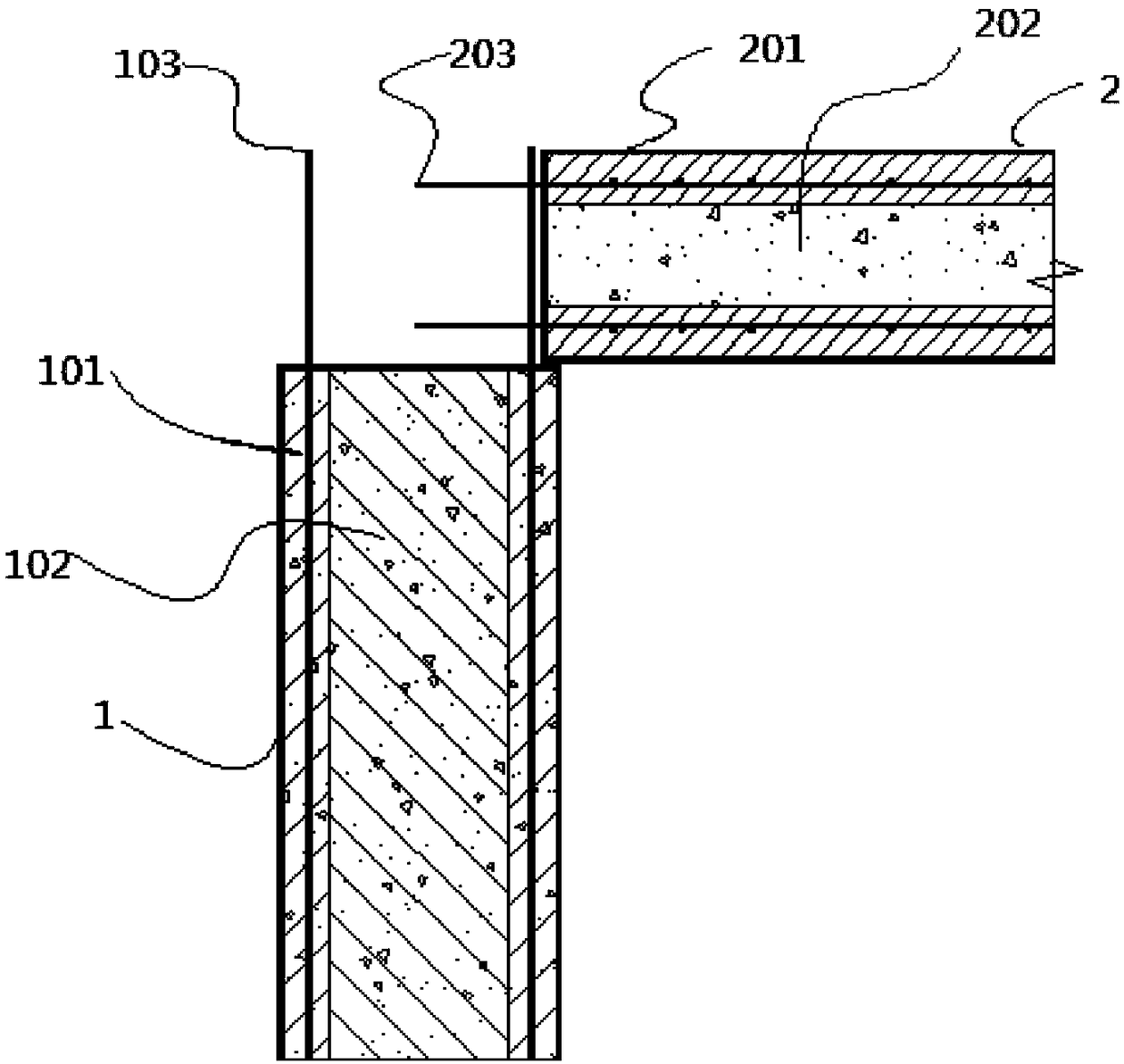

The invention relates to a non-pressed pipeline reinforcing structure for a road surface and a construction method for the non-pressed pipeline reinforcing structure. The non-pressed pipeline reinforcing structure comprises a road surface embedded groove, wherein a base layer is arranged in the road surface embedded groove. The non-pressed pipeline reinforcing structure is characterized in that symmetrically-distributed blocking assemblies are arranged on the two sides of the base layer and the top ends of the blocking assemblies are connected with a cover board; meanwhile, a separation assembly is arranged on the cover board, and a sealed protective space is formed among the blocking assemblies and the cover board and filled with a filling layer; a pipeline reinforcing assembly is arranged on the base layer; each blocking assembly comprises a bottom base material layer provided with a lateral reinforcing wall; and guide slopes are distributed at the two ends of the upper portion of the base layer and the pipeline reinforcing assembly is located at the joint of the guide slopes. Therefore, water can be prevented from flowing in transversely, external transverse force can be effectively borne, and an inner pipeline is protected against impact; the pipeline can be better prevented from being corroded by seeping underground water; and more importantly, the deformation characteristic is better while firmness is good, and the structure cannot crack easily.

Owner:苏州同尚工程设计咨询有限公司

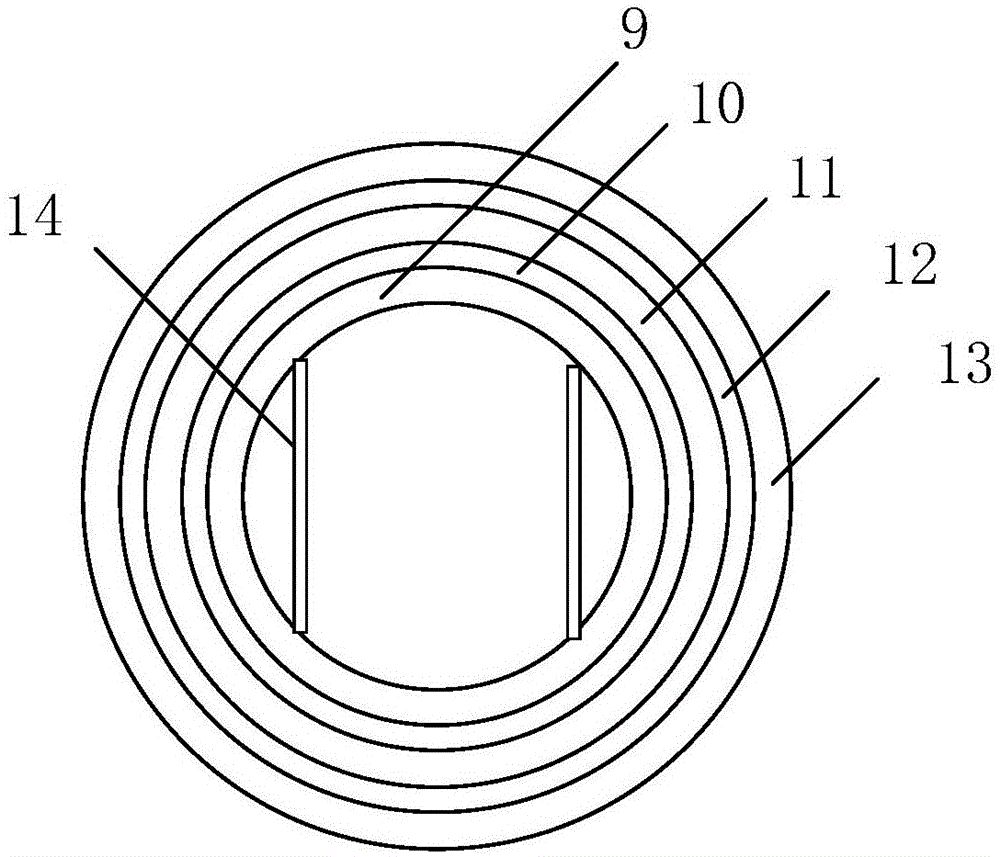

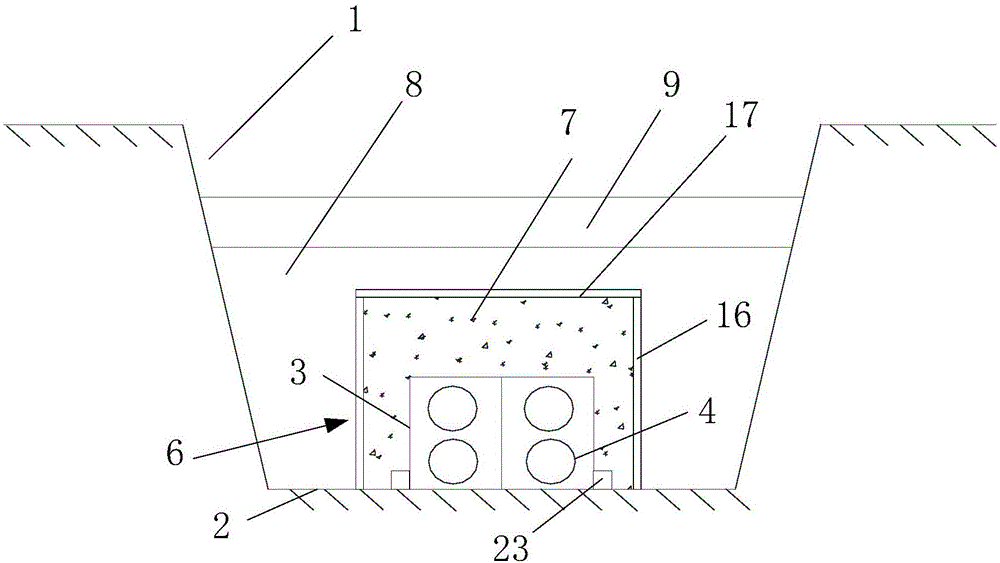

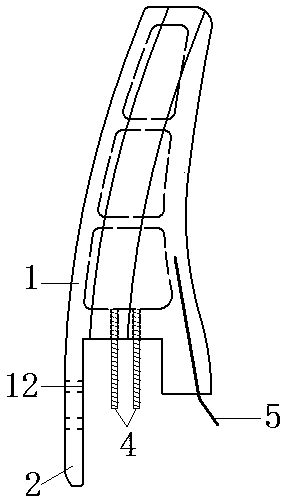

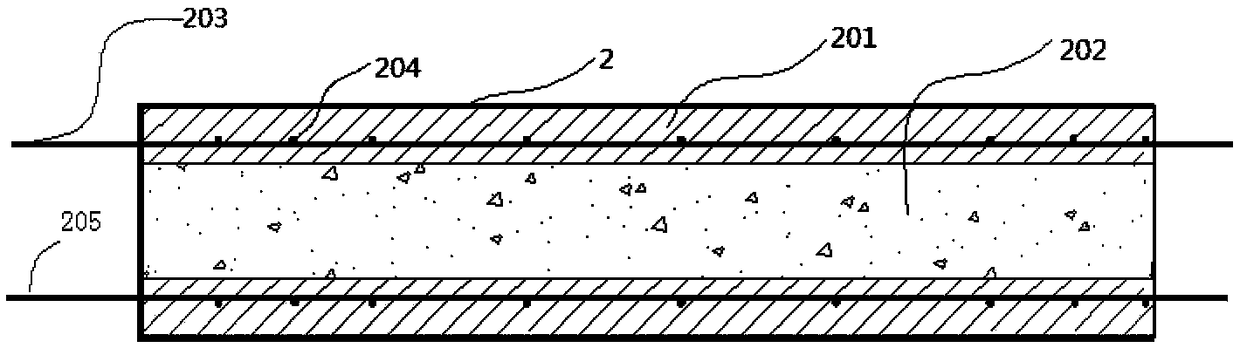

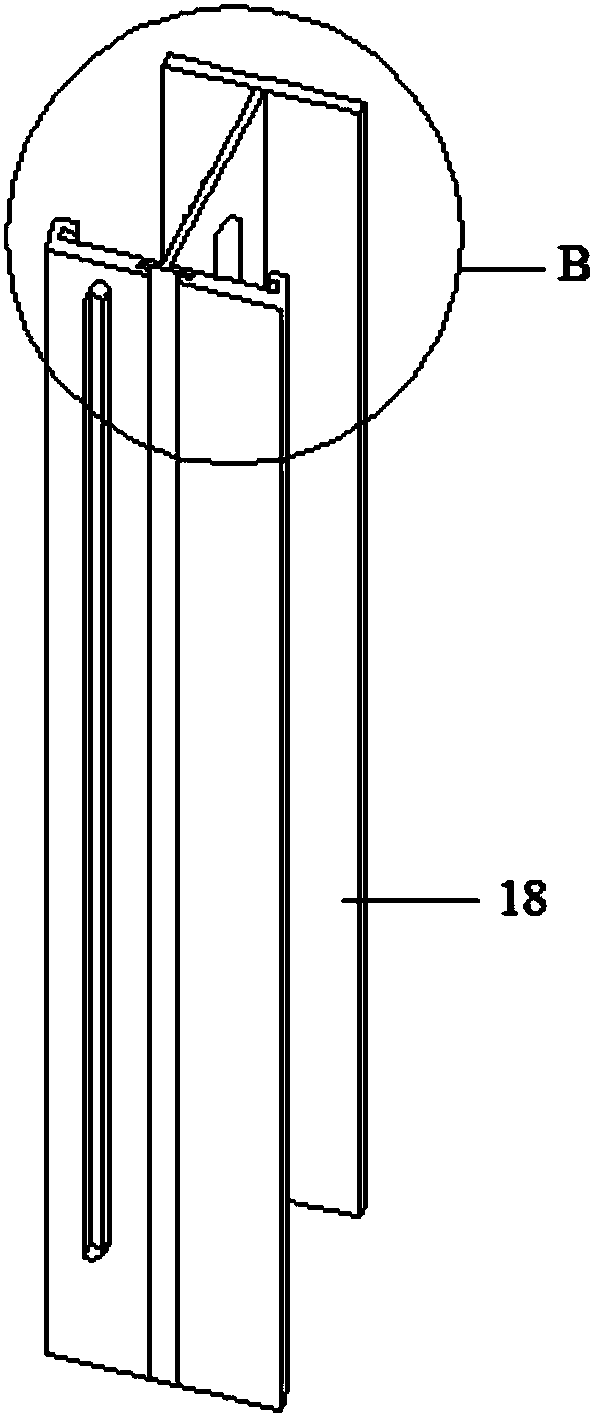

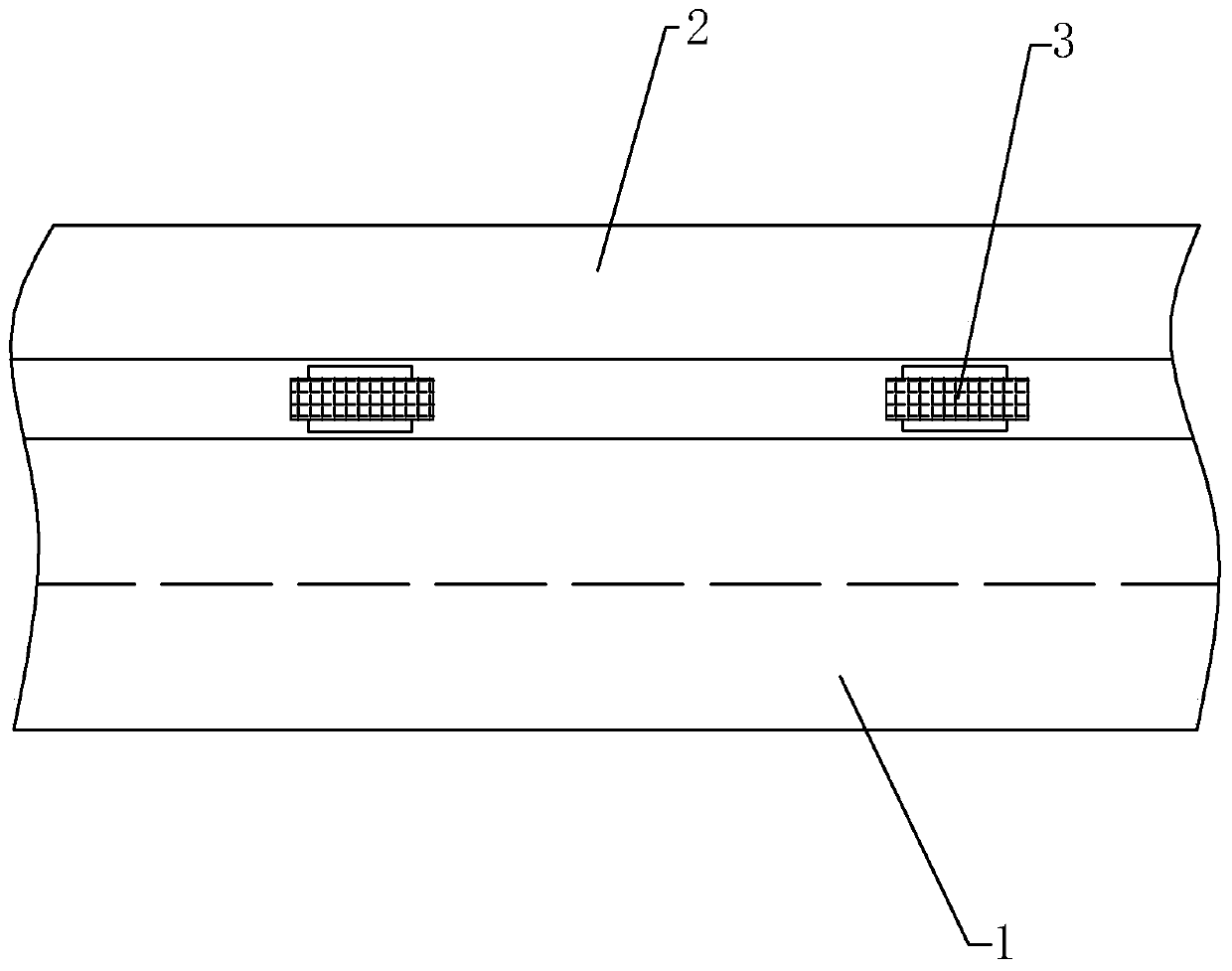

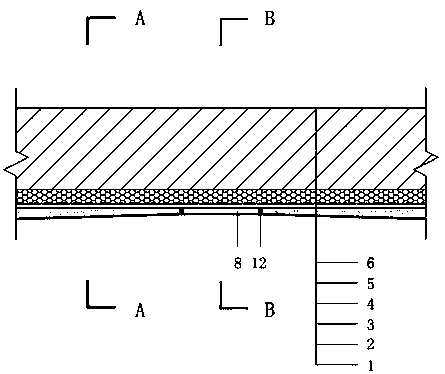

Pre-buried pipeline suitable for pavement shallow layers

ActiveCN105113354ANot affectedPrevent penetration corrosionTemporary pavingsPaving detailsRoad surfaceMechanical engineering

The invention relates to a pre-buried pipeline suitable for pavement shallow layers. The pre-buried pipeline comprises a pavement pre-buried groove, wherein a foundation layer is arranged in the pavement pre-buried groove. The pre-buried pipeline is characterized in that a pipeline strengthening assembly is arranged on the foundation layer; supporting channels are distributed in the pipeline strengthening assembly; auxiliary supporting rods are arranged in each of the supporting channels; besides, partition assemblies are distributed at the periphery of each of the supporting channels; a filling layer is arranged between the partition assemblies and the periphery of each of the supporting channels; a back-filling layer is distributed in the pavement pre-buried groove, and a blocking layer is distributed on the back-filling layer. Therefore, the laying requirement of multiple pipelines is met, and besides, the pre-buried pipeline can effectively bear external stress, so that an internal pipeline can be protected from being stricken, and underground water can be prevented from permeating into the pipeline and eroding the pipeline; in addition, the pipeline can bear downward longitudinal stress from the ground, so that the longitudinal extrusion for a subsequent pipeline is avoided.

Owner:苏州同尚工程设计咨询有限公司

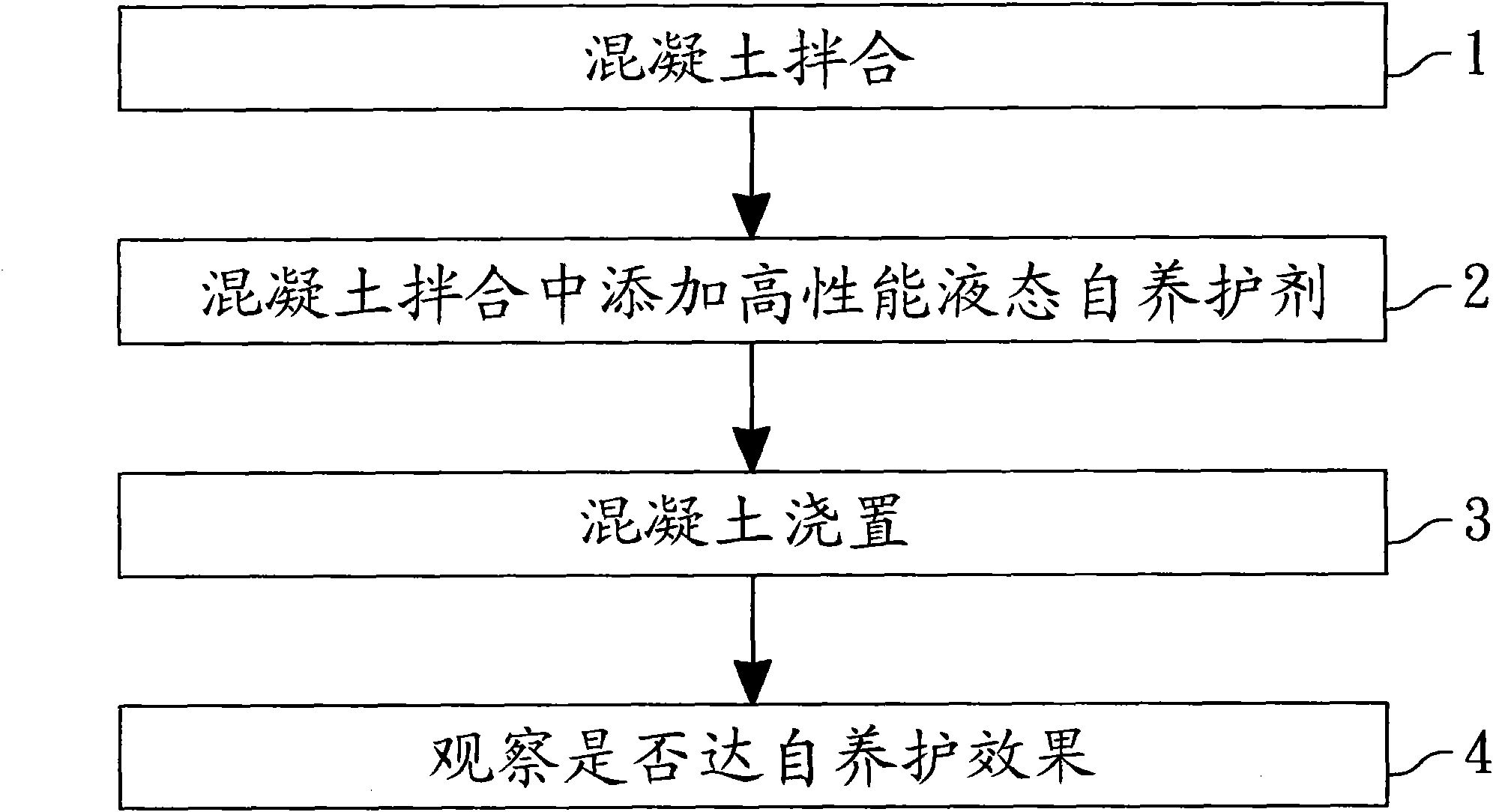

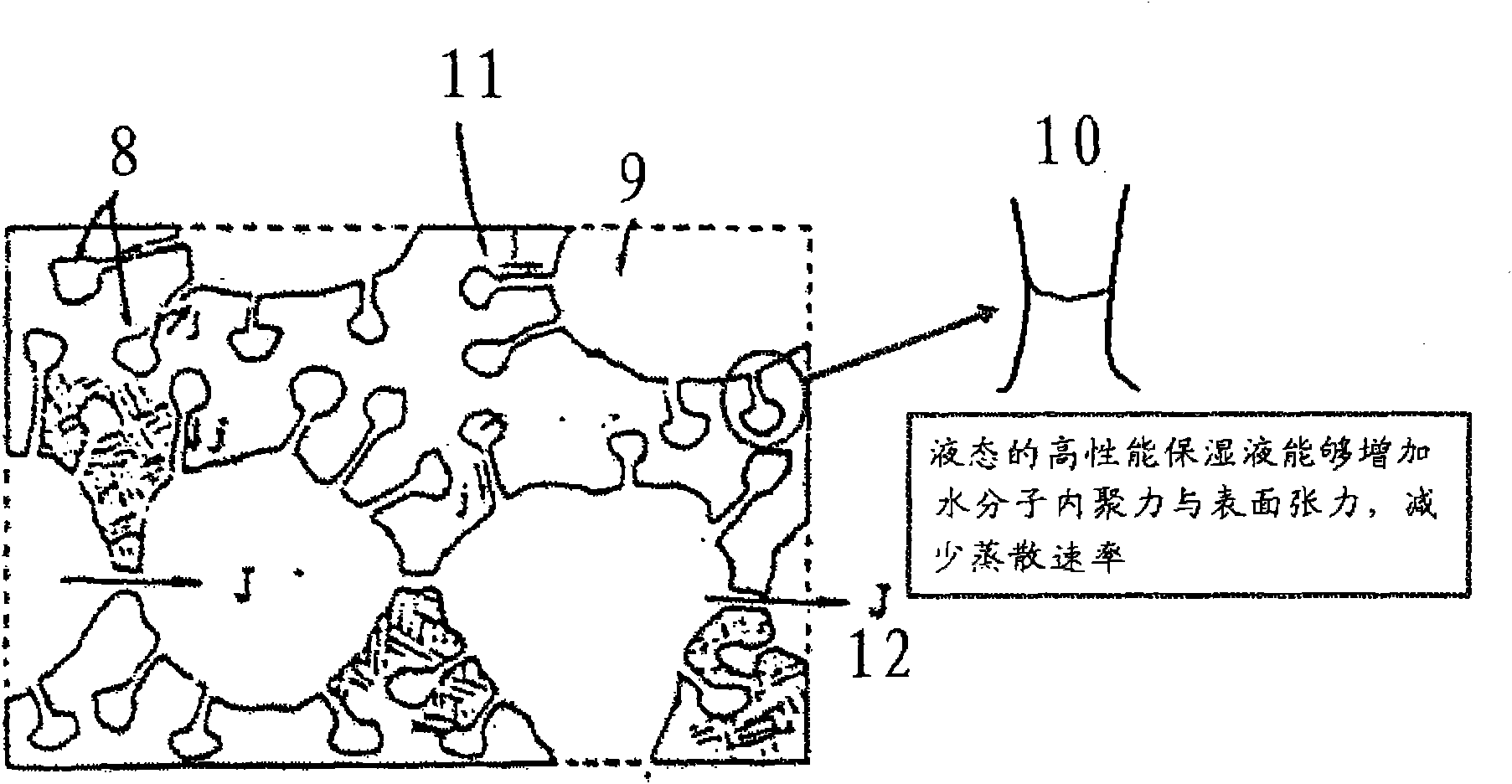

Self-curing concrete

The invention relates to self-curing concrete capable of preventing moisture from being excessively evapotranspired on the surface of concrete so as to solve the problem that the development of concrete does not meet the requirement due to incomplete cement hydration caused by curing failure in the prior art. A high-performance liquid self-curing agent is added into blended concrete, and the using amount of the high-performance liquid self-curing agent is 0.01 to 10 weight percent of powder in the concrete; and the high-performance liquid self-curing agent can absorb aqueous vapor in the air and release moisture to the concrete, so that after the concrete is poured, the concrete does not need extra moisture or any external curing to fulfill the self-curing aim.

Owner:赵文成

Secondary circuit conductor straightener

ActiveCN103600007ATowards a glanceTowards a beautiful and tidyCable installation apparatusVertical planeSecondary loop

A secondary circuit conductor straightener is characterized in that the straightener comprises a housing, the housing is composed of upper and lower housings folded and closed through hinges, two pairs of rolls in a same vertical plane are disposed inside the housing, each pair of rolls includes upper and lower rolls fixed inside the upper and lower housings through rotating shafts respectively, the upper and lower rolls fit peripherally and are provided with a plurality of corresponding slots, and the housing is provided with a conductor inlet and a conductor outlet corresponding to the slots. The secondary circuit conductor straighter is simple in structure and convenient to use, maintenance efficiency can be improved significantly, and no damage is caused to the outer insulating layer of each conductor.

Owner:STATE GRID CORP OF CHINA +1

Porous concrete vegetation brick, preparation method thereof and application

InactiveCN106278345ALow costFast greening effectBuilding componentsReceptacle cultivationVegetationBrick

The invention provides a porous concrete vegetation brick, a preparation method thereof and application. The product is excellent in breathability, has a certain nutritional ingredients and appropriate pH conditions and is filled with nutrient soil to plant plants. The plants completely cover a brick base frame, root systems of the plants go deep into the porous concrete brick base frame, and a decoration building material similar to a tile or cultured stone is formed. According to three-dimensional greening environmental characteristics, the prefabricated vegetation brick which can be applied to wall greening construction can be manufactured, and a convenient, quick and low-cost construction mode is provided for wall greening. In sum, the porous concrete vegetation brick is simple and practical, does not need to be fixed through a welding steel frame and is cheap in cost, economical, quick in greening effect and long in service life, the convenient, quick and low-cost construction mode can be provided for wall greening, and the porous concrete vegetation brick has an excellent popularization prospect.

Owner:广州市绿风生物技术有限公司

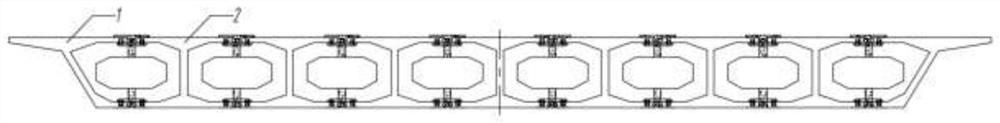

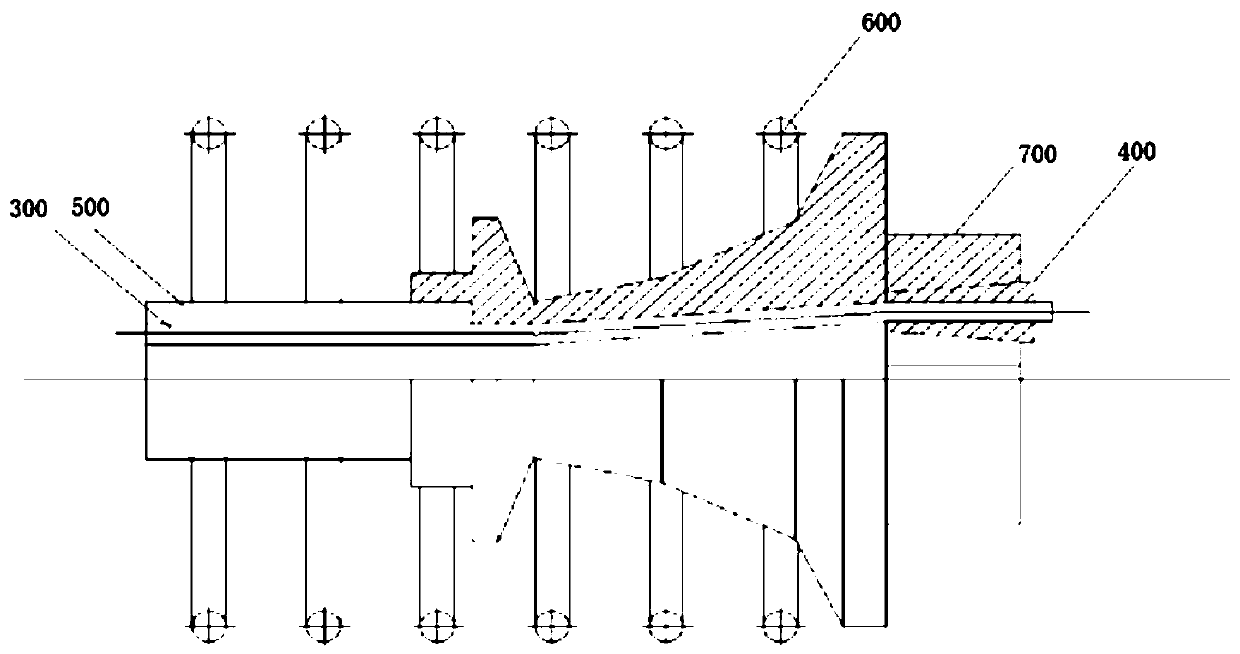

Novel construction method for upper structure of multi-chamber continuous UHPC box girder bridge

ActiveCN111877182AReasonable designImprove mechanical performanceBridge erection/assemblyBridge materialsSupporting systemArchitectural engineering

The invention discloses a novel construction method for an upper structure of a multi-chamber continuous UHPC box girder bridge. The method invloves UHPC prefabricated longitudinal block middle beams,UHPC prefabricated longitudinal block boundary beams, cast-in-place UHPC joints, prefabricated steel connecting pieces, shear nails, embedded steel base plates, embedded bolts, temporary supports, permanent supports, stiffening cross beams, cast-in-place UHPC bottom plates, cast-in-place UHPC webs, cast-in-place UHPC top plates, thickening areas, simply supported system main beams, stiffening cross beam bottom plates and main beam webs. The method has the beneficial effects that multi-chamber UHPC box girders are longitudinally partitioned for prefabrication and are spliced and connected through the specially-made connecting pieces on site, a plurality of multi-chamber simply-supported box girders are formed firstly, and then the box girder structure is changed from a simply-supported mode to a continuous mode through a special pouring mode on the pier. The structure is excellent in quality, reliable in splicing, good in stress performance and durability, convenient to construct, capable of greatly shortening the construction period and saving the under-bridge space, and very suitable for the requirements of construction and development.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

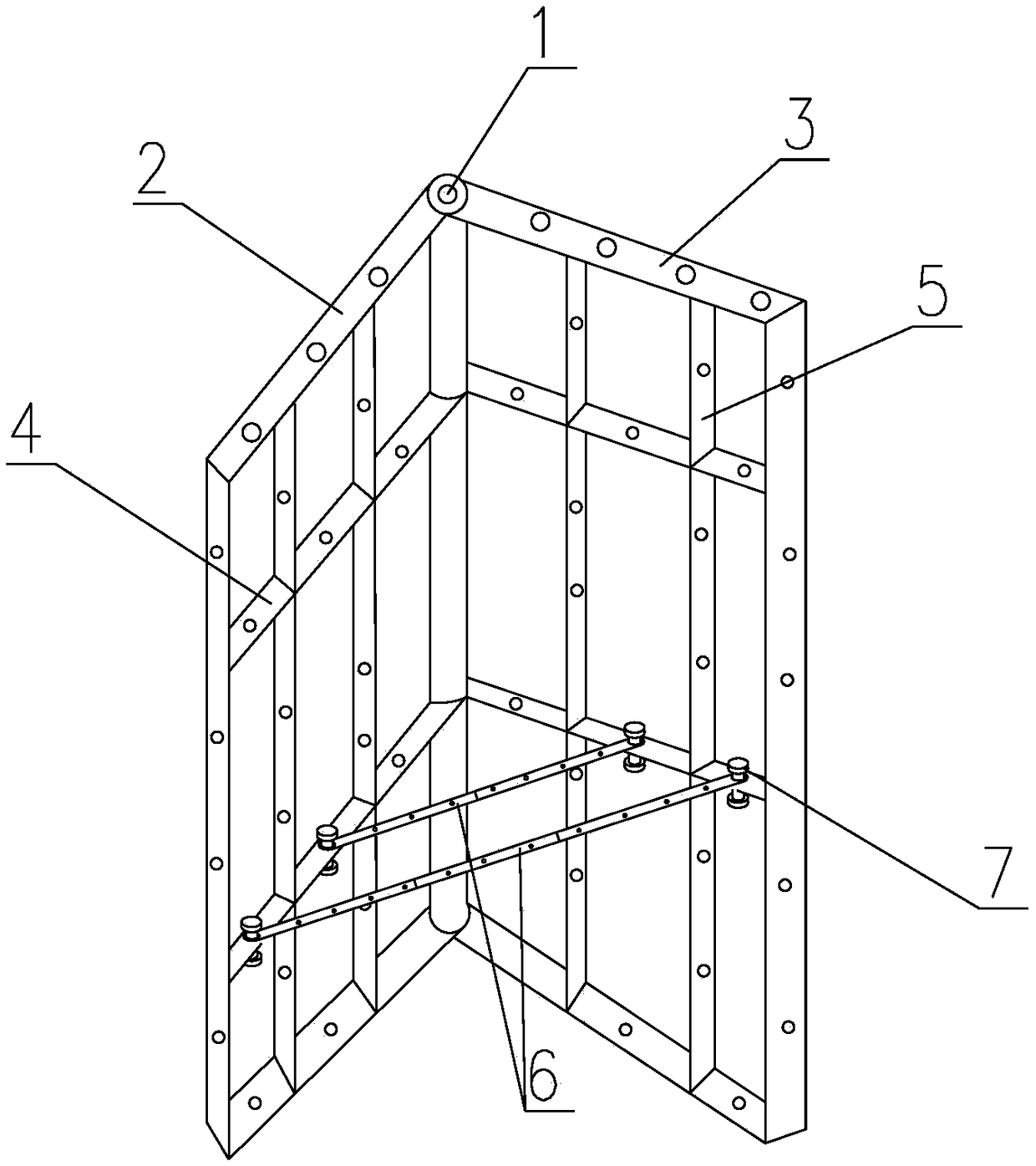

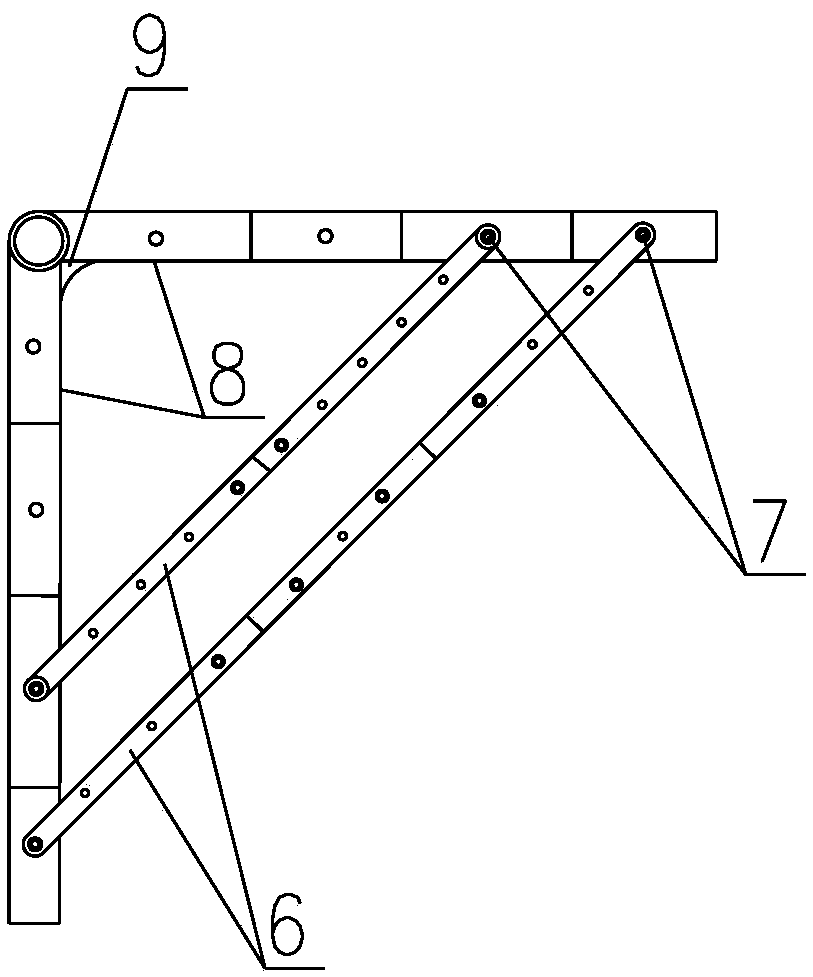

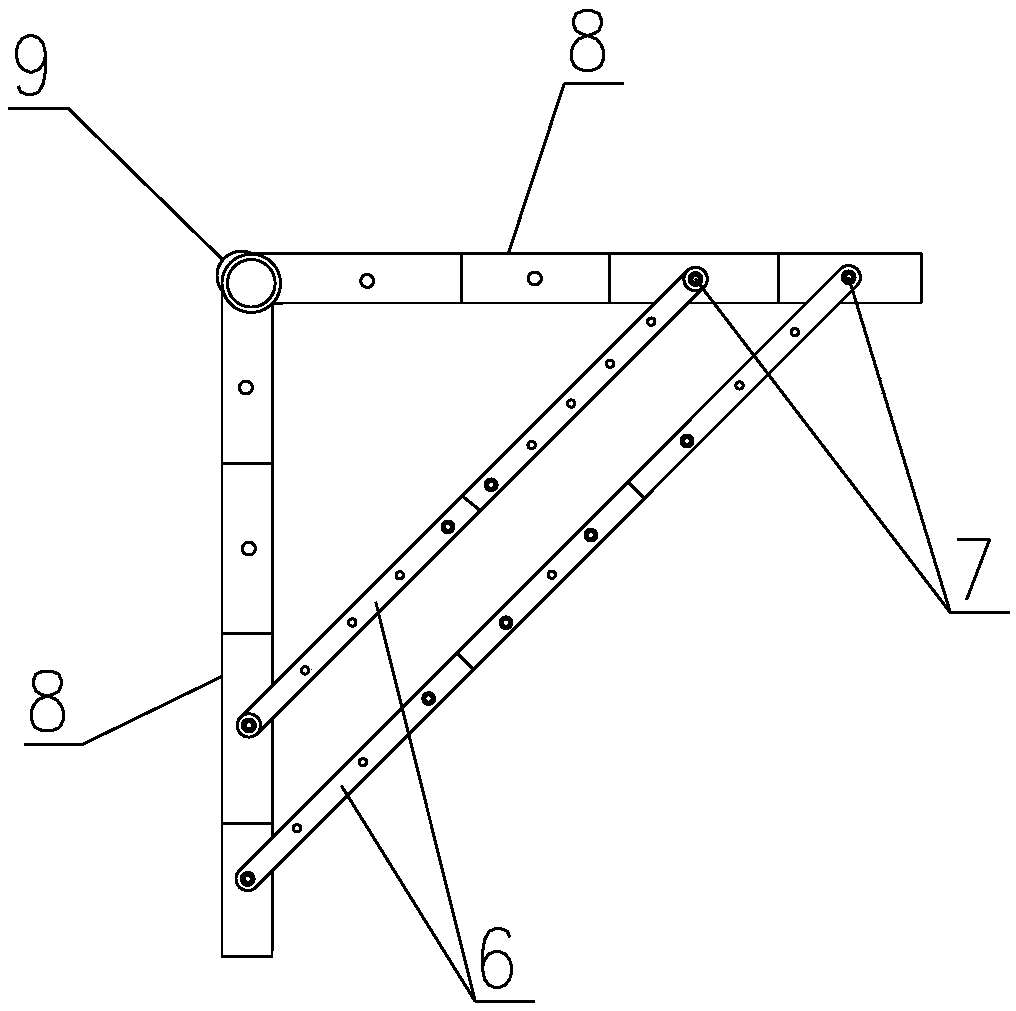

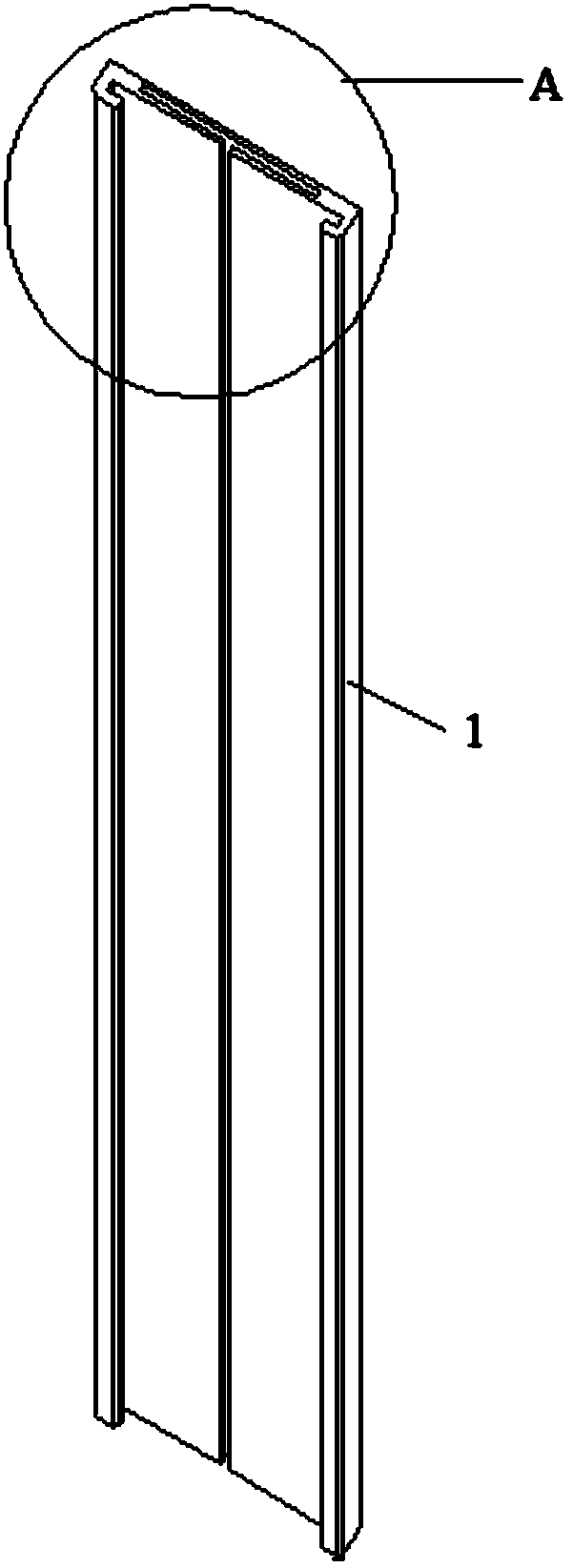

Frame structure system and construction method thereof

ActiveCN108343148AHigh strengthImprove stress resistanceProtective buildings/sheltersShock proofingConcrete beamsLap joint

The invention provides a frame structure system and a construction method thereof. The frame structure system comprises a plurality of composite columns and composite beams. Each composite column comprises a prefabricated column mold shell and a cast-in-situ concrete column inner core. Each composite beam comprises a prefabricated beam mold shell and a cast-in-situ concrete beam inner core. The top side of each prefabricated beam mold shell is provided with a grouting hole and an exhaust hole. 1-20cm of the end head of each composite beam is in lap joint with the edge of the top side of the corresponding composite column. The composite beams and the composite columns are connected through cast-in-situ concrete to form beam-column joints. The end heads of beam rebars of the composite beamsextend out of the ends of prefabricated beam mold shells and are anchored in the cast-in-situ concrete of the beam-column joints. The construction method comprises the following steps that prefabricated column mold shells are hoisted to the predetermined positions; the cast-in-situ concrete beam inner cores of the composite columns are formed through grouting; the prefabricated beam mold shells are hoisted, and 1-20cm of the end heads of the prefabricated beam mold shells are in lap joint with the edges of the top sides of the prefabricated column mold shells; templates at the beam-column joints are erected; the cast-in-situ concrete beam inner cores of the composite beams are formed through grouting; the concrete at the beam-column joints is grouted; and the steps are repeated until construction of the building frame is completed.

Owner:江苏千禧杭萧装配式建筑科技有限公司

Connecting mould plate for inside corner and outside corner and with adjustable angle

Owner:CHINA THIRD METALLURGICAL GRP

A lightweight assembled anti-collision fence assembly and an installation method thereof

InactiveCN109162202AImprove toughnessAvoid secondary damageBridge structural detailsEngineeringRebar

A lightweight assembled anti-collision guardrail assembly and an installation method thereof are disclosed. The lightweight assembled anti-collision guardrail assembly comprises prefabricated guardrails, a vertical bolt, a horizontal bolt, a steel bar and bridge flange panels, the bridge flange plate is provided with a vertical bolt hole and a horizontal bolt hole, the vertical bolt is installed at the bottom of the prefabricated guardrail, inserted into the vertical bolt hole, the horizontal bolt is inserted into a horizontal bolt hole through a prefabricated guardrail, and the prefabricatedguardrail is welded together after the prefabricated guardrail is just joined with the reinforcing bars of the bridge flange plate, and the prefabricated guardrail is prefabricated in segments, and the bottom part is formed into an inverted shape, and is sequentially installed on the bridge flange plate. The prefabricated guardrail is connected with the reinforcing bars of the bridge flange plate,and the reinforcing bars are arranged in a vertical bolt staggered manner. The invention provides a lightweight assembled anti-collision guardrail with good mechanical performance, strong anti-collision ability, durability, good toughness, light dead weight, short construction period and easy guarantee of construction quality.

Owner:HUNAN UNIV

Phosphate wear-resistant paint and spraying method thereof

The invention discloses a phosphate wear-resistant paint which comprises the following components in parts by mass: 12-16 parts of 3-5mm high bauxite, 18-25 parts of 1-3mm high bauxite, 10-15 parts of 0-1mm high bauxite, 6-12 parts of 0-1mm silicon carbide, 16-28 parts of high bauxite powder, 8-12 parts of aluminum hydroxide powder, 5-10 parts of Suzhou sludge, 8-15 parts of calcined alumina powder, 2-5 parts of silicon micropowder, 1-3 parts of oxalic acid and 1-2 parts of high-alumina cement. The spraying method comprises the following steps: uniformly mixing the raw materials, adding the mixture into a spraying machine, adding a phosphoric acid solution, uniformly mixing, adding the phosphoric acid solution at the spray gun outflow, and carrying out spraying construction. The phosphate wear-resistant paint product has the advantages of favorable binding strength, high adhesive rate, high setting rate, high medium / high-temperature strength, favorable wear resistance, favorable thermal shock stability, favorable mechanical wear resistance and favorable erosion resistance, is convenient for construction, and can be widely used in discharge hoods, grate coolers, kiln tail smoke-box moon gates, cyclone burners, tertiary air pipes and other irregular positions.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

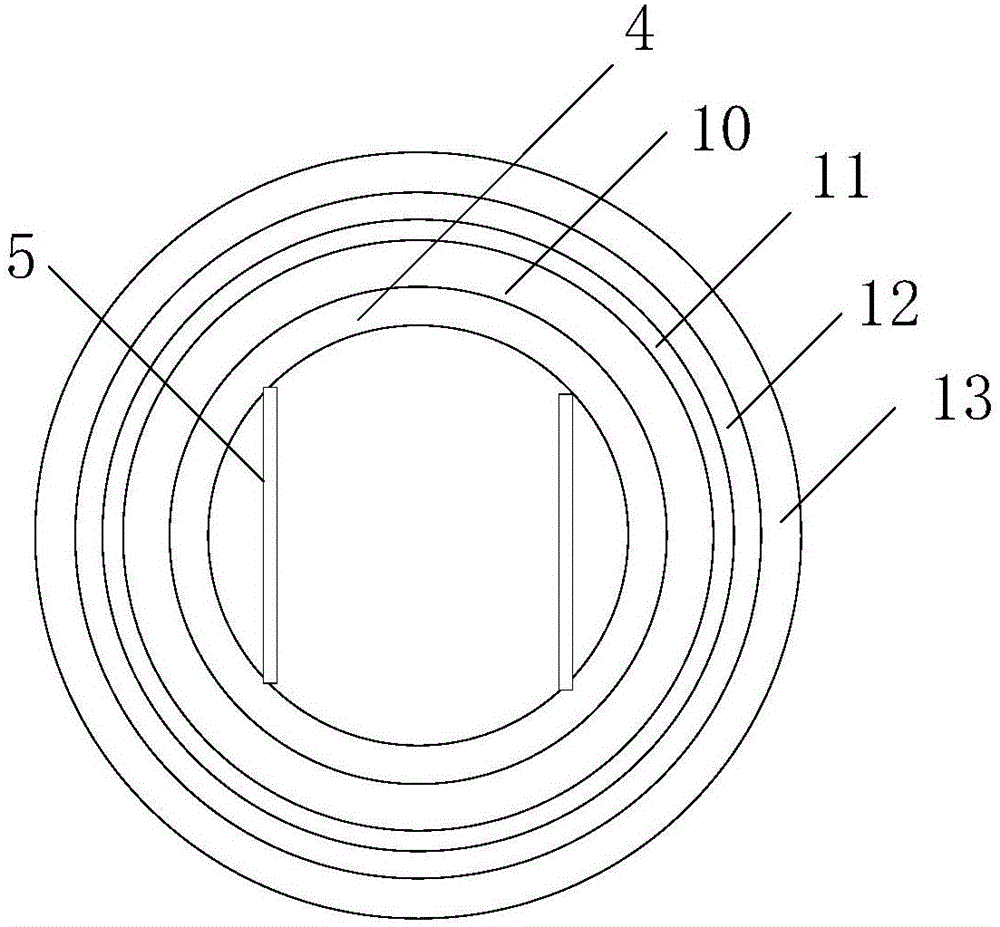

Novel prestressed cable structure based on shape memory alloy

InactiveCN110387805AReduce the loss of prestressImprove leaping abilityCable-stayed bridgeBridge structural detailsRebarPre stress

The invention discloses a novel prestressed cable structure based on shape memory alloy. The structure comprises a shape memory alloy intelligent anchor cable, a shape memory alloy intelligent anchormainly comprises a shape memory alloy spiral cable, a shape memory alloy pipe joint, a prestressed reinforcement, a shape memory alloy clamp and spiral reinforcements, and the shape memory alloy clampis mainly composed of a shape memory alloy anchoring clamping sheet; the shape memory alloy anchoring clamping sheet is inserted in an anchoring hole, and the prestressed reinforcement penetrates through the shape memory alloy spiral cable and is connected with the shape memory alloy spiral cable through the shape memory alloy pipe joint. According to the novel prestressed cable structure, by adopting the shape memory alloy clamp, the shape memory alloy pipe joint and the shape memory alloy spiral cable, the loss of prestress is lowered, the spanning capability of the structure is improved, the mechanical property, crack resistant property and durability of the structure are improved, so that the prestressed reinforcement in the structure is beneficial to maintenance of the structure in the operation period, and the service life of the structure is prolonged.

Owner:BEIJING JIAOTONG UNIV

Art flexible face brick and construction method thereof

InactiveCN104727500ASolve all hidden dangersHigh bonding strengthCovering/liningsBrickArchitectural engineering

The invention relates to an art flexible brick and a construction method thereof. The art flexible brick comprises a caulking leveling course which is arranged on the external surface of a base layer; the external surface of the caulking leveling course is provided with a base enamel layer; the external surface of the base enamel layer is provided with a face brick sizing layer; the external surface of the face brick is provided with a waterproof enamel layer. The construction method of the art flexible brick comprises the following steps of base layer processing, caulking leveling course preparation, base enamel layer preparation, caulking, shape arrangement, face brick sizing layer preparation, face brick sizing layer shaping, cleaning and polishing and waterproof enamel layer preparation. The art flexible brick has the advantages that the materials of the arc flexible face brick and materials of an insulating layer of a construction wall are same flexible materials; the technical index is similar, compatible and well matched, the bonding strength is high, the material is light, the construction is simple, the costs are low, the unit area load is light, the safety coefficient is high, and the construction method is simple; compared with a traditional pasting tile, the construction efficiency can be improved by 50% and the construction costs can be reduced by 10% to 20%; the construction is simple, costs are low, the bonding strength is high, flexible anti-crack and weather fastness performances are strong, the waterproof air permeability is strong, and fade is not easy.

Owner:PINGDINGSHAN UNIVERSITY

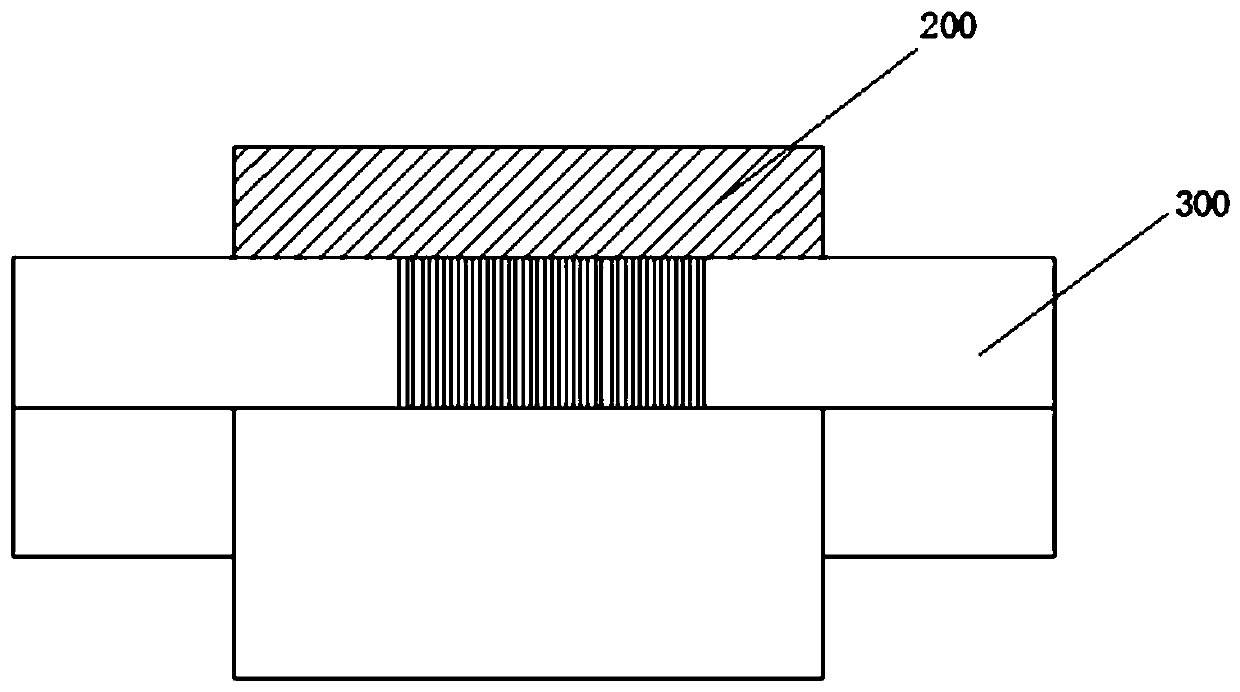

Beam column joint and construction method thereof

ActiveCN108301510AHigh strengthImprove stress resistanceBuilding constructionsConcrete beamsLap joint

The invention provides a beam column joint and a construction method thereof. The beam column joint comprises a composite column and a composite beam. The composite column comprises a prefabricated column mould shell and a cast-in-place concrete column inner core, the composite beam comprises a prefabricated beam mould shell and a cast-in-place concrete beam inner core, and a grouting hole and anexhaust hole are formed in the top side of the prefabricated beam mould shell. The portion, within 1-20cm, of the end of the composite beam is in lap joint to the edge of the top side of the compositecolumn, and the composite beam and the composite column are connected through cast-in-place concrete to form the beam column joint. The end of a beam reinforcing steel bar of the composite beam extends out of the end of the prefabricated beam mould shell and is anchored in the cast-in-place concrete of the beam column joint. The length of the beam reinforcing steel bar anchored in the beam columnjoint is 35 to 40 times the diameter of the beam reinforcing steel bar. The construction method comprises the following steps that the prefabricated column mould shell is hoisted to a predetermined position; the cast-in-place concrete column inner core of the composite column is poured and formed; the prefabricated column mould shell is hoisted and the portion, within 1-20cm, of the end is in lapjoint to the edge of the top side of the prefabricated column mould shell; a formwork is arranged at the beam column joint; the cast-in-place concrete beam inner core of the composite beam is pouredand formed; and concrete at the beam column joint is poured.

Owner:河南三禾建筑工程有限公司

Steel plate pile and support construction method for foundation pit

ActiveCN109235445AAvoid deformationEasy to reuseExcavationsBulkheads/pilesSheet steelArchitectural engineering

The invention discloses a steel plate pile and a support construction method for a foundation pit, wherein the steel plate pile comprises a steel plate, the steel plate is a strip-shaped and both endsof the steel plate are provided with a lock catch matching part, the steel plate is sunken inwards in the middle part of the vertical side face near the lock catch matching part to form a first groove along the height of the steel plate, which is vertical through, and whose cross section is T-shaped; an H-shaped steel, which comprises a web plate and a pair of wing plates which are vertically fixed on two sides of the H-shaped steel, the H-shaped steel includes a first wing plate and a second wing plate that are equal in width to the steel plate, and the H-shaped steel is matched with the inner side portion of the first groove, and the first wing plate is provided with a lock catch matching part at both ends, the vertical side of the outer side of the first wing plates sunken inwards to form a second groove, which is vertical through, and whose cross section is T-shaped; the second wing plate is clamped in the first groove, and the steel plate and the H-shaped steel are spliced to form an H-shaped steel sheet pile. The steel plate pile has the advantages of convenient construction, stable structure, and the like, and the steel plate pile can be widely applied to the technical field of steel sheet pile and foundation pit support construction method.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

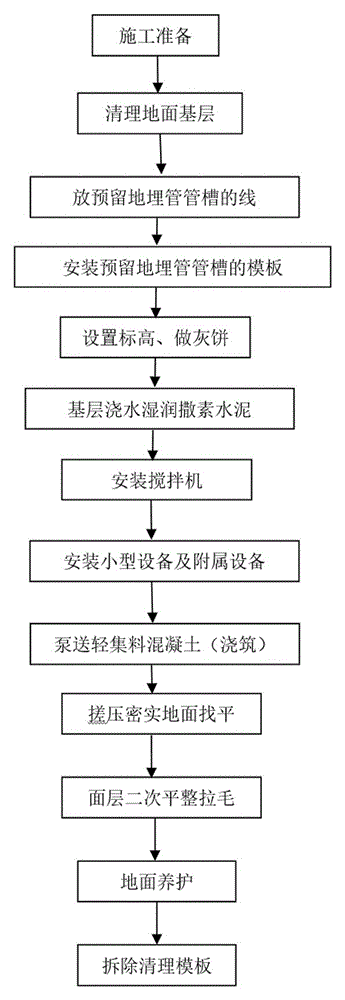

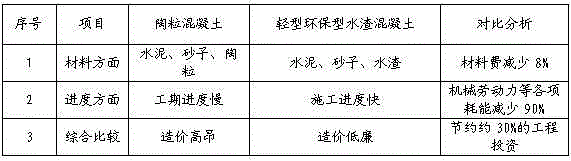

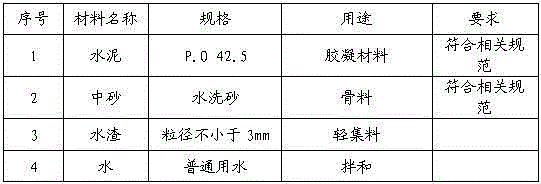

Construction method for environment-friendly light concrete cushion

ActiveCN105002918AEasy constructionGuarantee the construction qualityFoundation engineeringSlagExpanded clay aggregate

The invention relates to a construction method for an environment-friendly light concrete cushion. The construction method includes the following steps that a ground base layer is cleaned; an elevation is set, ash plates are manufactured according to the set elevation, and the distance of the ash plates is not larger than 2 m; water is spread on the ground base layer for moistening, and plain cement mortar is swept to form a combination layer; environment-friendly light concrete is poured on the ground base layer, and the environment-friendly light concrete is formed by stirring cementing materials, aggregate, light aggregate and water; the light aggregate is water granulated slag; rubbing, pressing, compacting and leveling are conducted; the poured environment-friendly light concrete is rubbed, pressed and compacted, leveling is conducted through a scraping lever, and flat rubbing is conducted through a float; secondary flattening is conducted before the environment-friendly light concrete is finally set, and roughening is conducted; the environment-friendly light concrete is maintained. According to the construction method, a series of construction problems that a traditional ceramsite concrete ground technology is complex, particles float, and compactness is poor are solved; in addition, environmental friendliness is achieved, construction is convenient, time and labor are saved, the construction quality can be ensured, a construction period can be shortened, and investment can be reduced.

Owner:中东基建科技集团有限公司

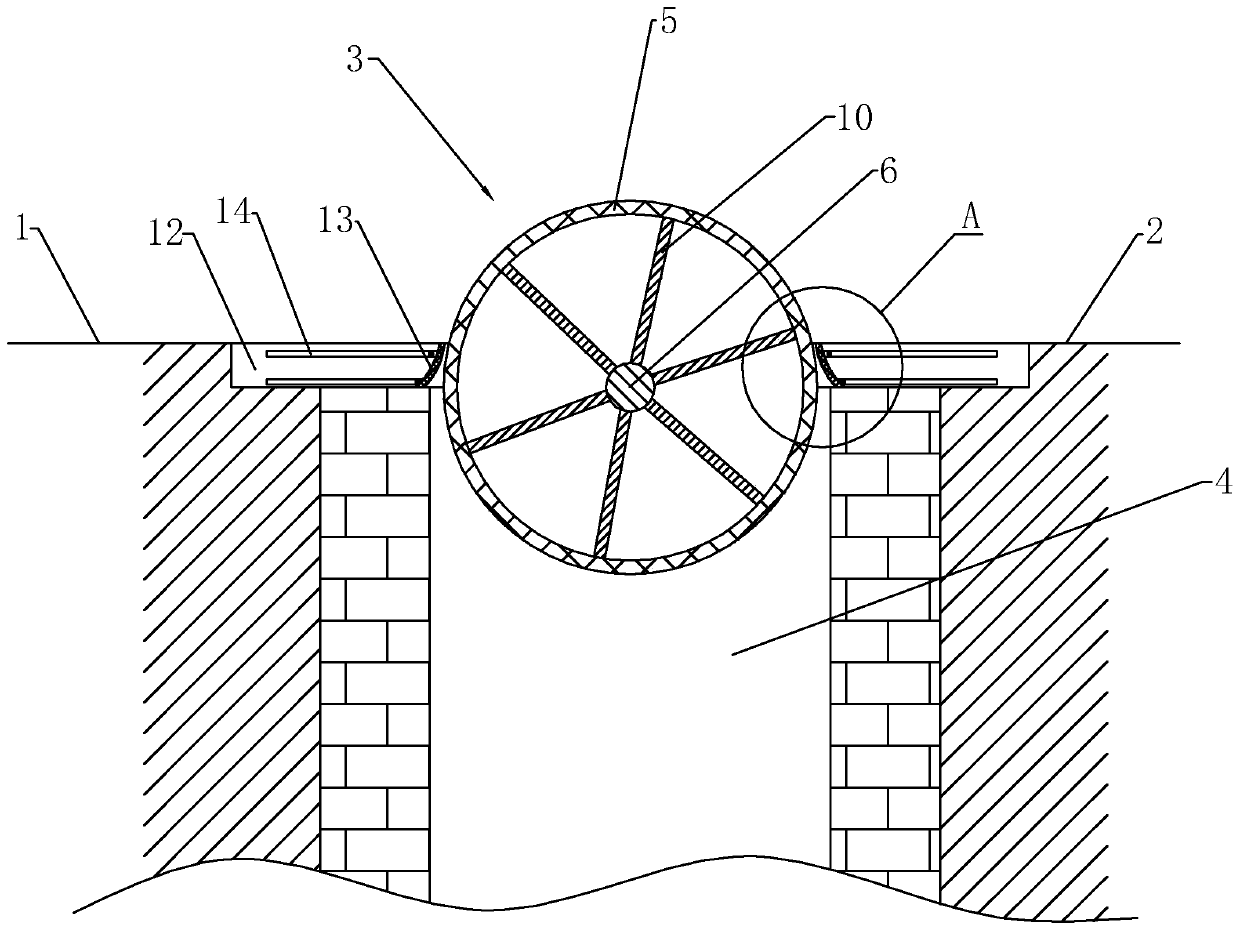

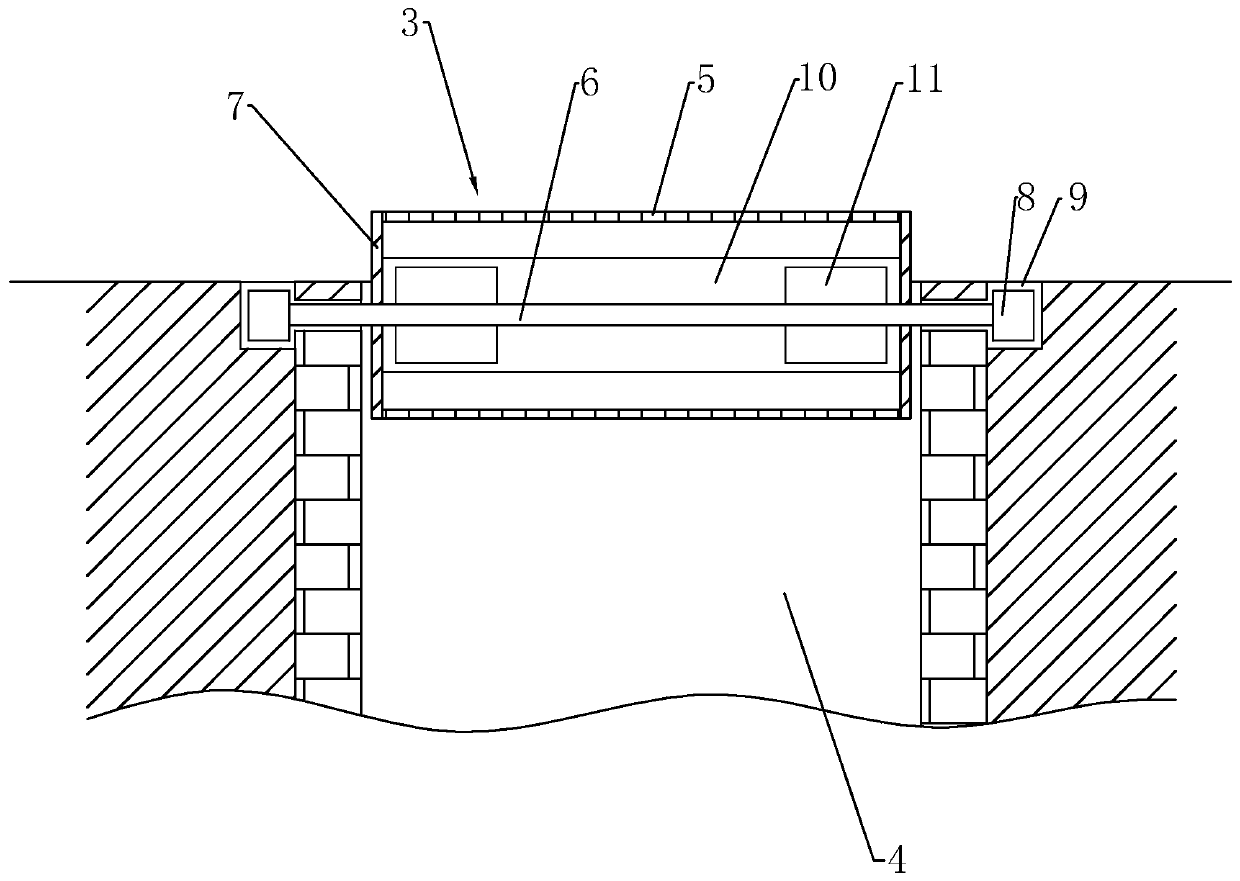

A drainage structure for municipal roads

The invention discloses a drainage structure of a municipal road and a construction method of the drainage structure. The drainage structure comprises a drainage well which is arranged between a motor way and a non-motorized vehicle lane, wherein a grating component is arranged at the well mouth of the drainage well; the grating component is of a cylindrical structure and the latticed component (the grating component) is transversely arranged at the well mouth of the drainage well; the grating component is arranged in a mode of being partially higher than the well mouth of the drainage well; the sides, close to the motor way and the non-motor way, of the edge of the well mouth of the drainage well are provided with concave accommodating grooves, and the sides, facing the well mouth, of the accommodating grooves are connected to the well mouth; the parts, connected to the well mouth, of the accommodating grooves are provided with filter screen frames; the filter screen frames are in clearance fit with the surface of the grating component; the grating component comprises a central shaft and blades which are connected between the outer circle of the grating component and the central shaft; the central shaft is rotatably connected to the inner wall of the drainage well; and two ends, in an axial direction of the grating component, of the blades are provided with hollowed-out parts. The drainage structure provided by the invention has the characteristics of being not easy to block and stable in drainage effect.

Owner:WENZHOU XINGHAI MUNICIPAL CONSTR

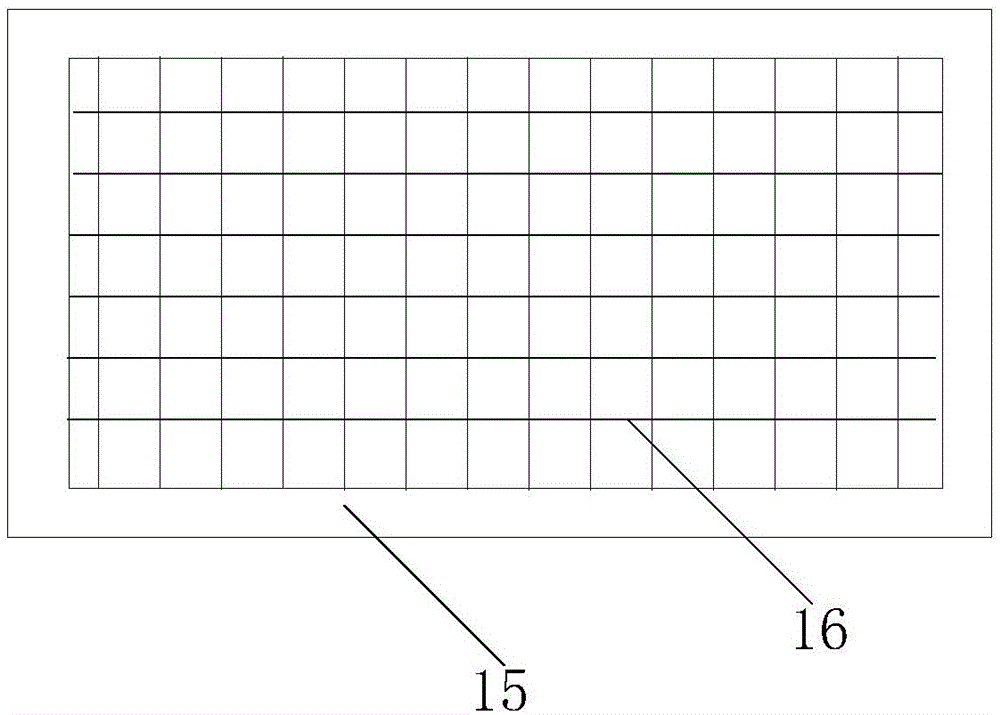

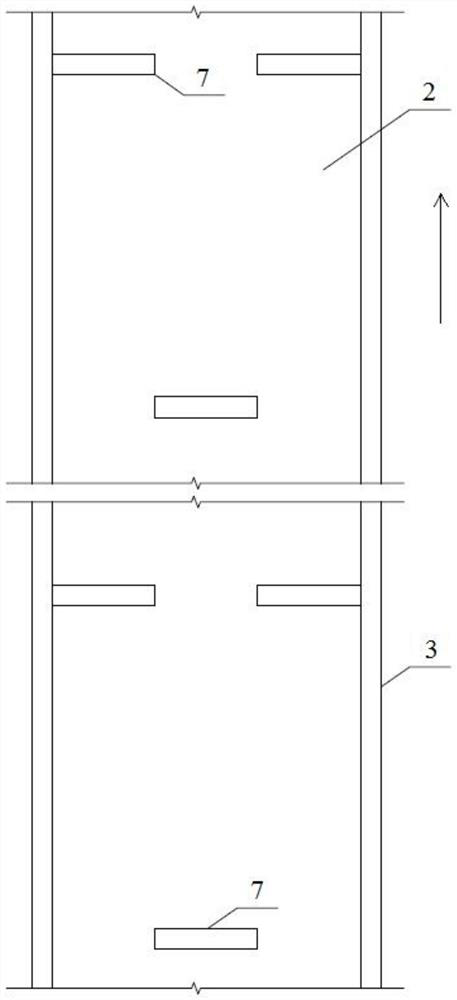

Dry and wet combined connection structure with prefabricated concrete floor slabs and construction method

ActiveCN113482208ASimple preparation processReliable power transmissionFloorsCeramic shaping apparatusFloor slabArchitectural engineering

The invention provides a dry and wet combined connecting structure with prefabricated concrete floor slabs and a construction method. The dry and wet combined connecting structure comprises the prefabricated concrete floor slabs, a connecting assembly and post-pouring concrete, a plurality of groups of first slotted holes and second slotted holes are arranged in the connecting side of the prefabricated concrete floor slab in a reserved mode the connecting assembly comprises steel plates and a connecting piece, the steel plates are fixed to the junctions of the first slotted holes and the second slotted holes, the connecting piece is used for connecting and fixing the two corresponding steel plates; and the post-pouring concrete is poured in the first slotted holes and the second slotted holes. According to the dry and wet combined connecting structure, the two adjacent prefabricated concrete floor slabs are firmly connected together, the integrity of the spliced prefabricated concrete floor slabs is guaranteed, the in-plane shear resistance, tensile strength, flexural rigidity and bearing capacity of the floor slabs are remarkably improved, deformation coordination when uneven loads are borne is achieved, and the using effect equal to that of cast-in-place floor slabs is achieved; and the manufacturing process is simple, industrialized production is achieved, on-site assembly construction is achieved, the construction speed is high, greenness and environment friendliness are achieved, the manufacturing cost is saved, force transmission is reliable, and integrity is good.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Microorganism reefing method of near-sea sand bank slope

The invention discloses a microorganism reefing method of a near-sea sand bank slope. The microorganism reefing method of the near-sea sand bank slope is characterized by comprising the steps of constructing an appropriate microorganism carrier, artificially introducing mineralizable microorganisms into an original sand bank so as to form specified conditions, and promoting the microorganisms in the sand bank to induce metal cations in sea water so as to generate precipitates or form a biological film sandy reefing protection bank. According to the microorganism reefing method of the near-seasand bank slope provided by the invention, the characteristic that mineralized products or extracellular secretion polymers of organisms can be cemented with loose particles is utilized, a nature coral reef building process is simulated through a manual intervention manner, and bionic controlled reefing layers or blocks are formed, so that the usage of a traditional cement and other cementing materials is reduced and even abandoned; the microorganism reefing method of the near-sea sand bank slope is suitable for amplifying far-sea island reefs and reinforcing the near-sea sand bank slopes; anda construction method is simple, convenient to implement, and helpful to form a micro-ecological system.

Owner:CHONGQING UNIV

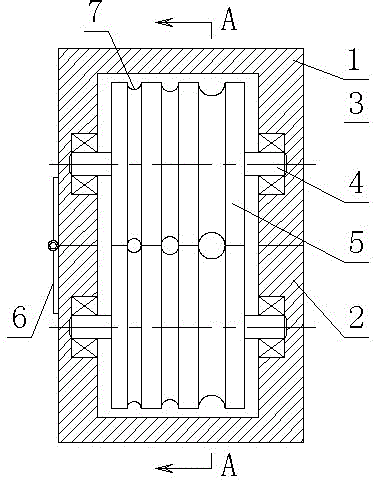

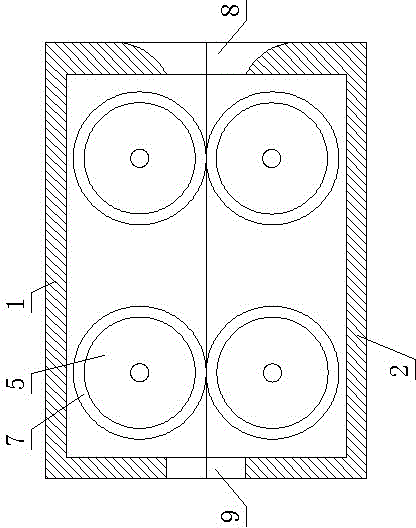

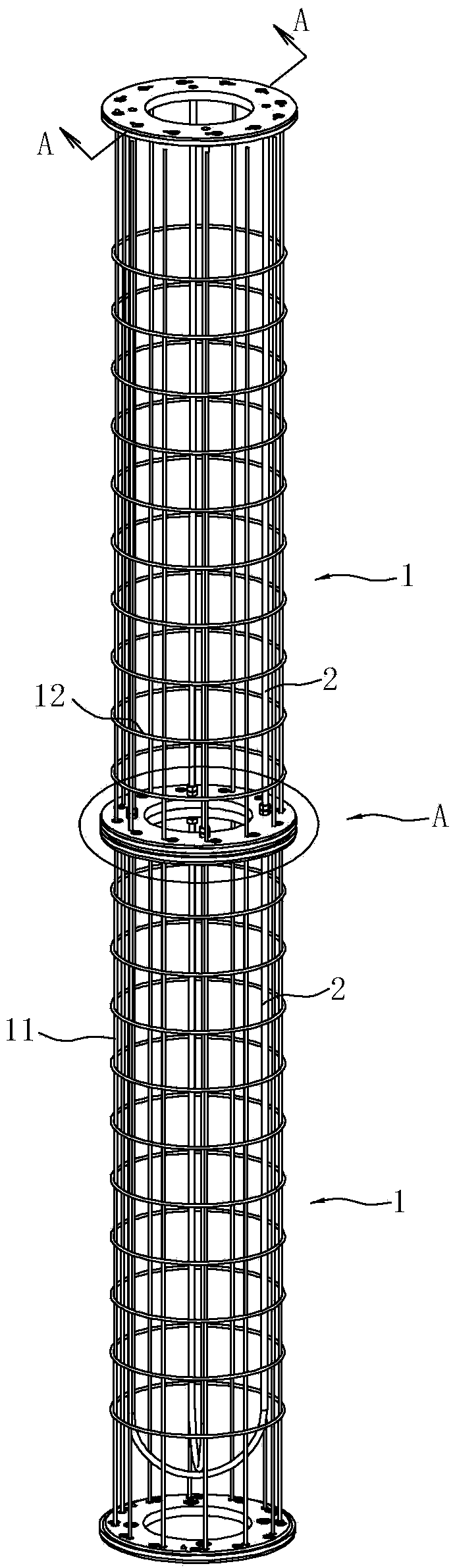

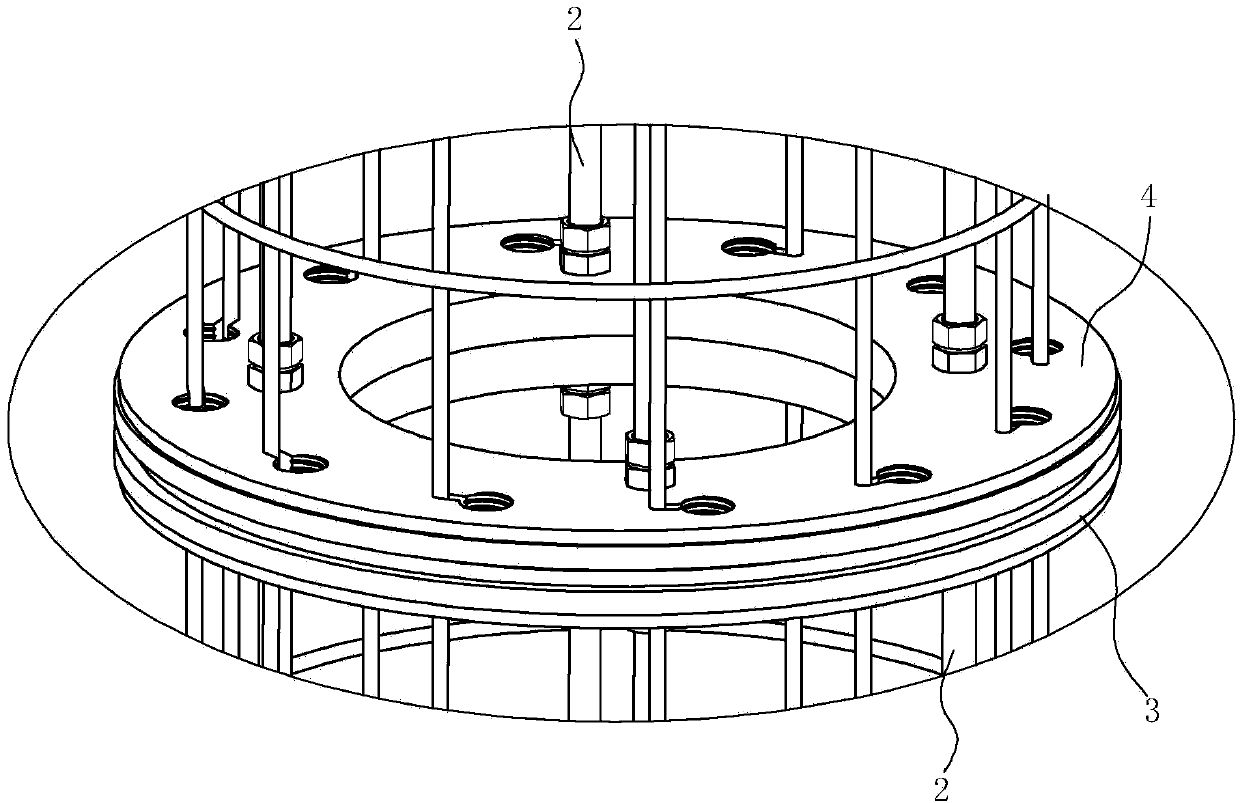

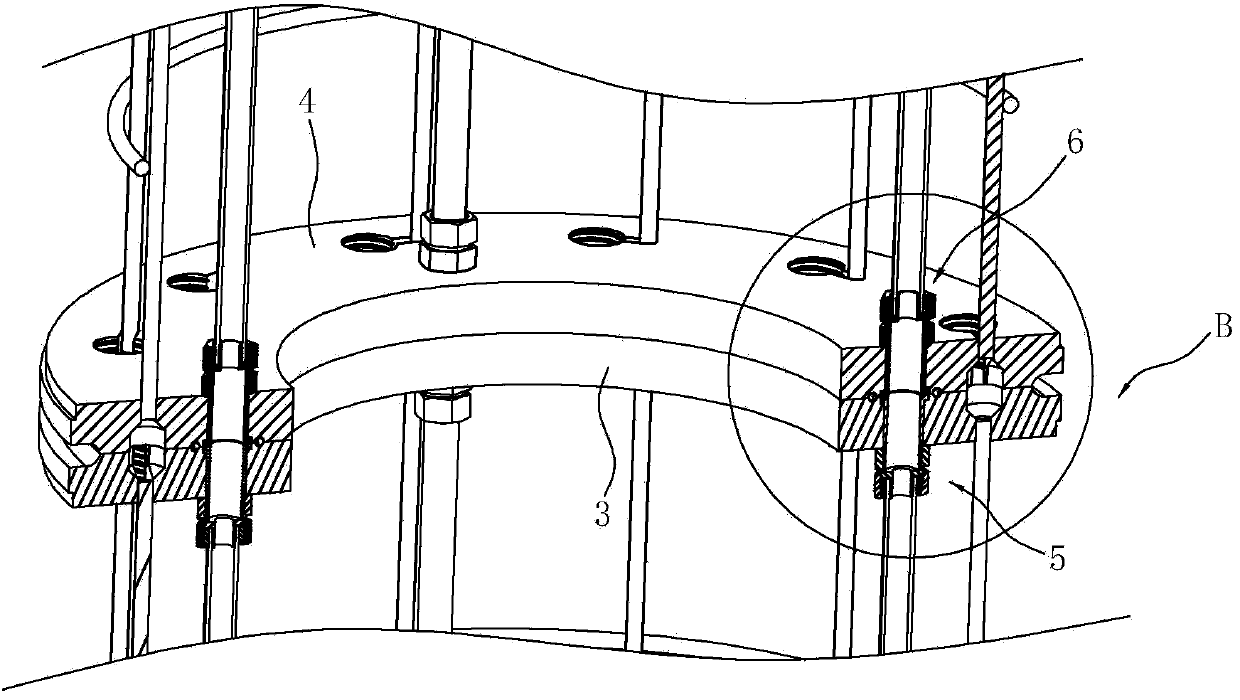

Energy column for saving energy of ground source heat pump

InactiveCN103741676AMeet specification requirementsSo as not to damageHeat pumpsBulkheads/pilesEngineeringAir source heat pumps

The invention discloses an energy column for saving energy of a ground source heat pump. The energy column comprises a plurality of tube piles which are connected in sequence from bottom to top, and a heat exchanger tube positioned in each tube pile, wherein two adjacent tube piles are connected with each other through a group of blind plates; each group of blind plates comprises an upper blind plate positioned on the upper portion of a next tube pile and a lower blind plate positioned on the lower portion of an adjacent previous tube pile; each upper blind plate is provided with a plurality of upper mounting holes; each lower blind plate is provided with a plurality of lower mounting holes; the upper end of each heat exchanger tube positioned in each next tube pile is arranged in each upper mounting hole through an upper connecting mechanism; the lower end of each heat exchanger tube positioned in each adjacent previous tube pile is arranged in each lower mounting hole through a lower connecting mechanism; in a state the upper blind plates and the lower blind plates are connected together, the lower mounting holes and the upper mounting holes are aligned one by one in order to correspondingly communicating the heat exchanger tubes in next tube piles with the heat exchange tubes in adjacent previous tube piles one by one. The energy column has a good stabilizing effect on the heat exchanger tubes. Meanwhile, the sealing property is ensured, and convenience is brought to construction.

Owner:ZHEJIANG YINQIAO ENERGY TECH DEV

Anti-corrosion and waterproof emulsified asphalt and preparation method thereof

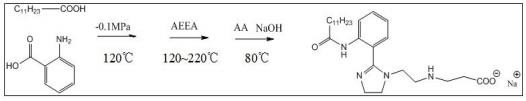

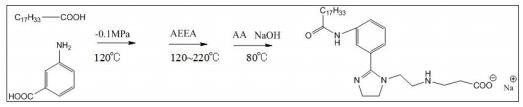

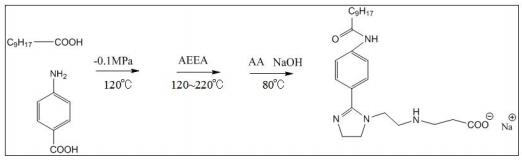

PendingCN113307986AGood emulsifying effectPromote chelationOrganic chemistryTransportation and packagingEpoxyBitumen emulsion

The invention discloses anti-corrosion and waterproof emulsified asphalt which is prepared from the following raw materials in parts by weight: 550 parts of matrix asphalt, 1-30 parts of an emulsifier, 2-50 parts of a modifier, 5-100 parts of a single-component waterborne epoxy emulsion, 0.1-5 parts of a stabilizer and a proper amount of distilled water. The invention provides high-performance emulsified asphalt. A high-performance water-based single-component epoxy emulsion and an imidazole asphalt emulsifier are adopted as raw materials and are matched with auxiliaries (such as a defoaming agent, a thickening agent, a dispersing agent, a stabilizer and the like) to obtain a water-based epoxy asphalt mortar product with efficient corrosion resistance and excellent waterproof and anti-seepage performance. The emulsified asphalt can be widely applied to water prevention and corrosion prevention of sewage pools and pipelines, can replace toxic and harmful products such as epoxy coal pitch and the like, is also widely applied to building waterproof engineering such as water prevention of toilets, roofs and basements, and is matched with hot-melt or self-adhesive asphalt coiled materials to be applied to coating and coiling composite waterproof engineering.

Owner:湖南林特科技有限公司

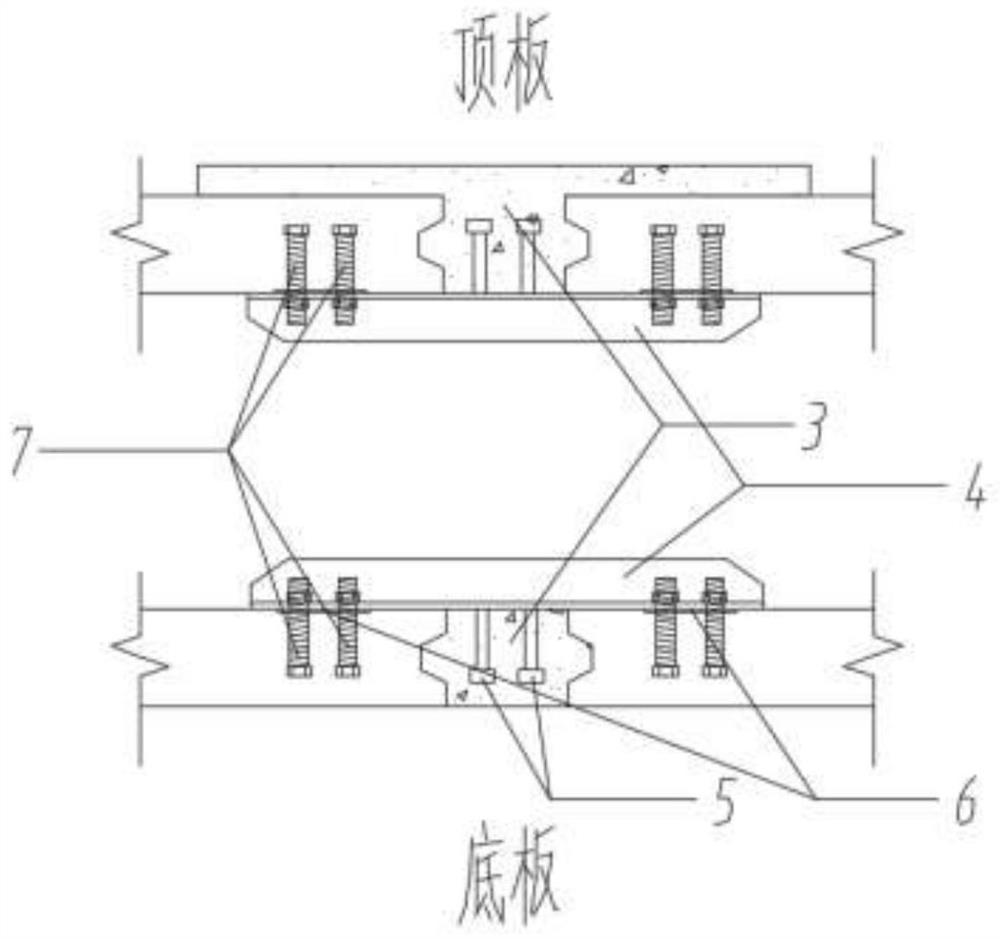

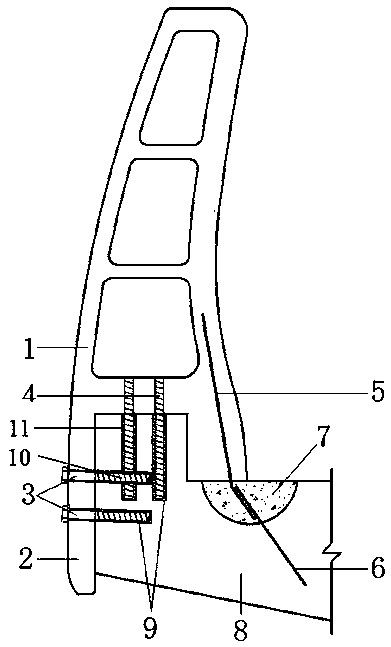

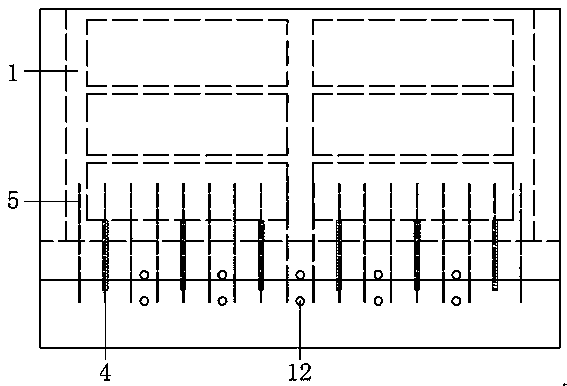

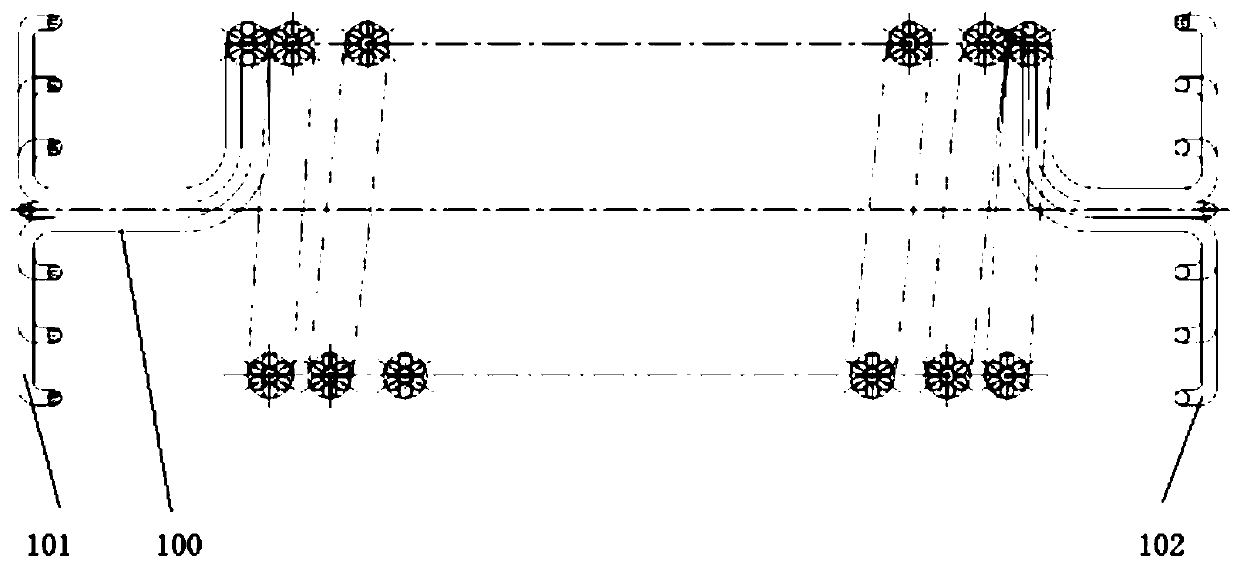

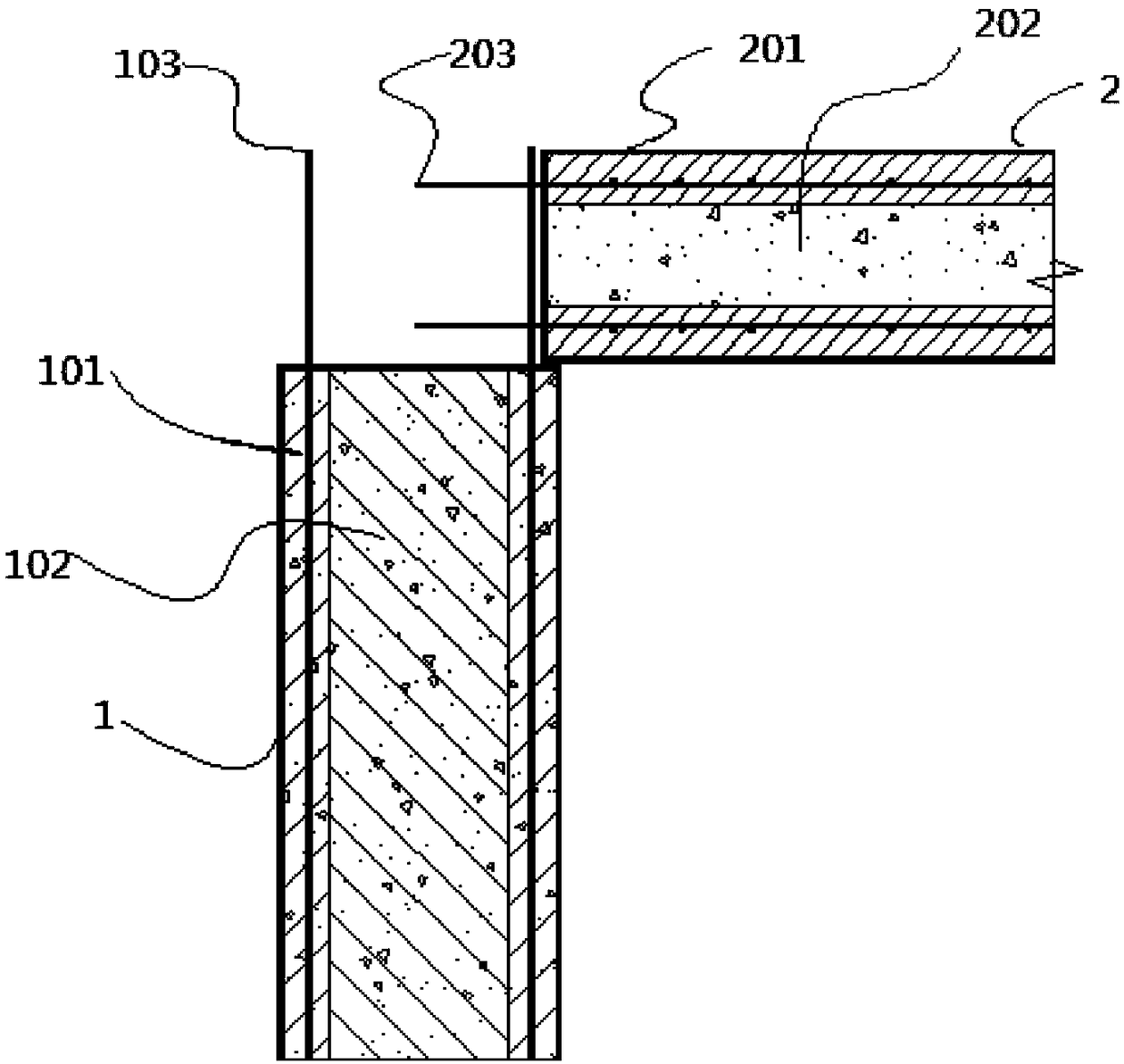

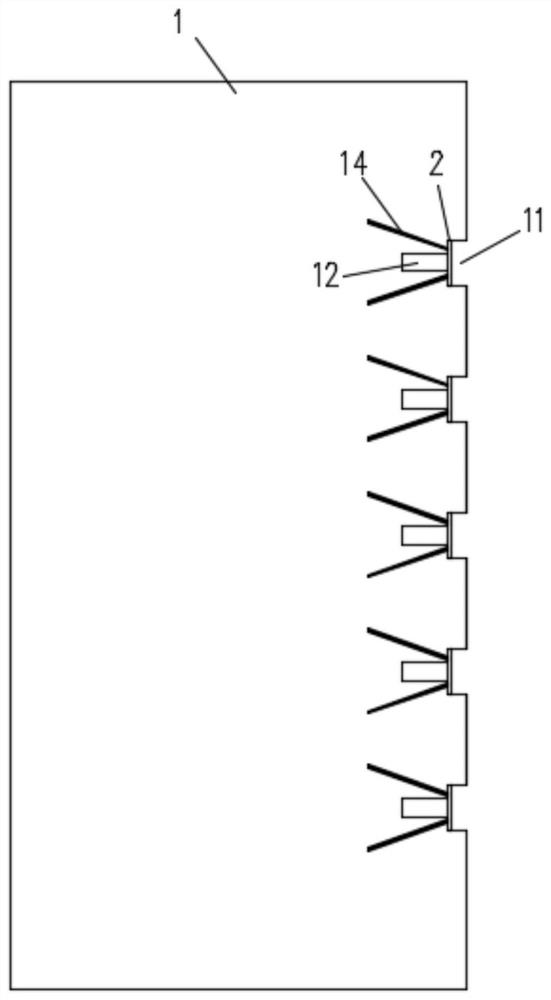

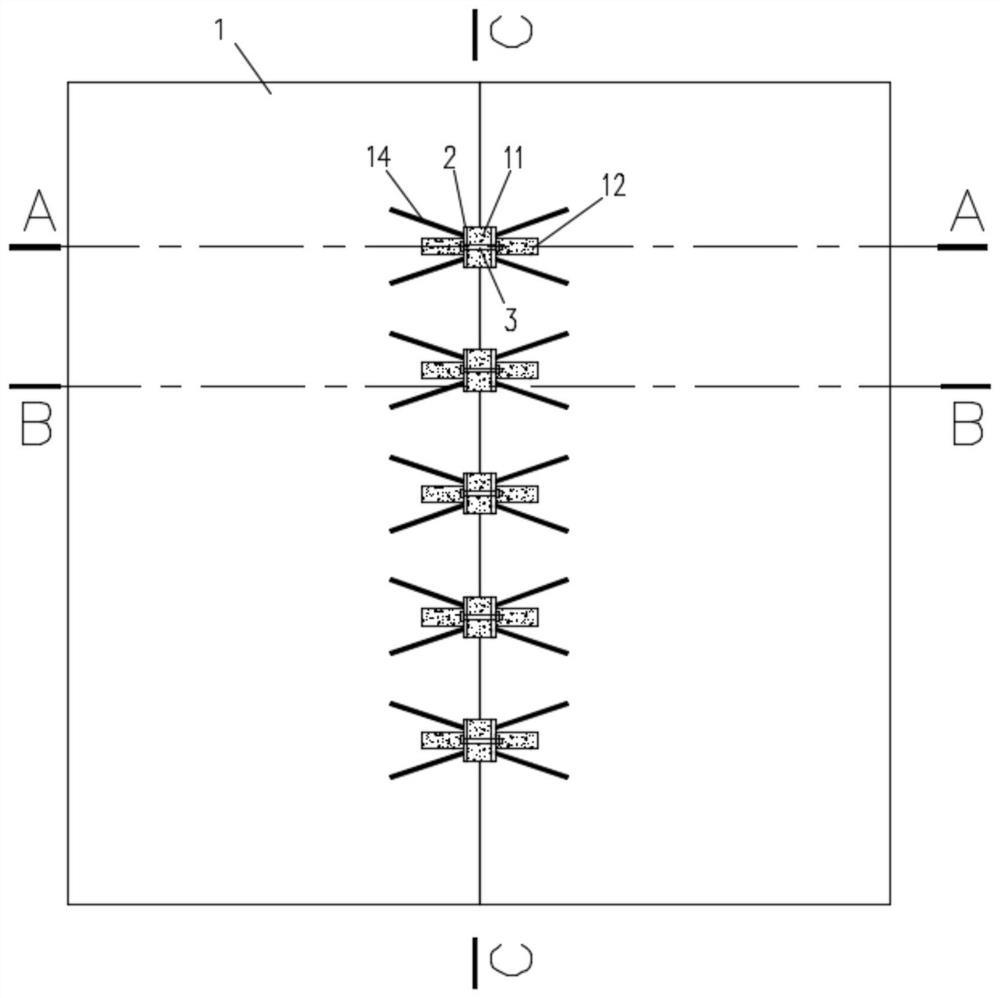

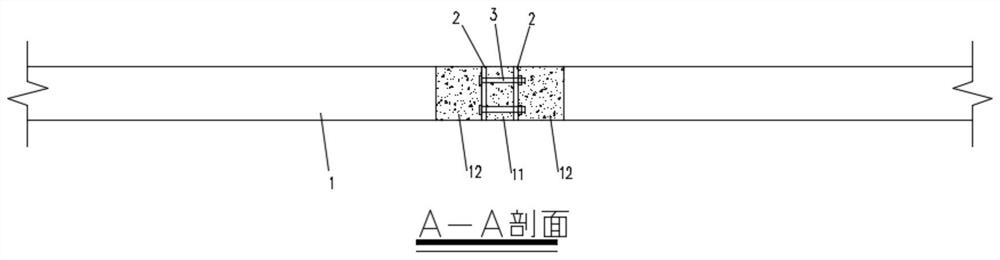

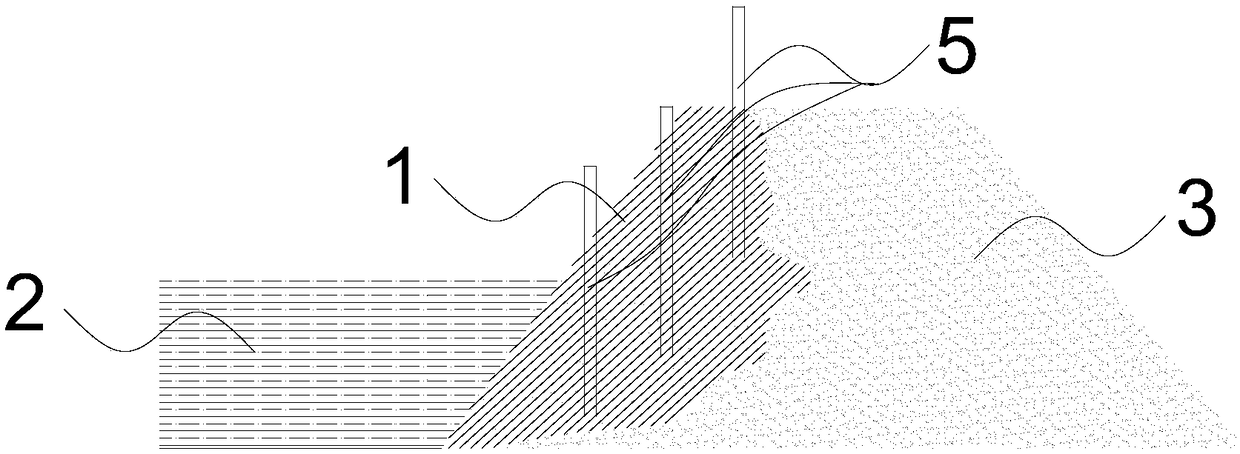

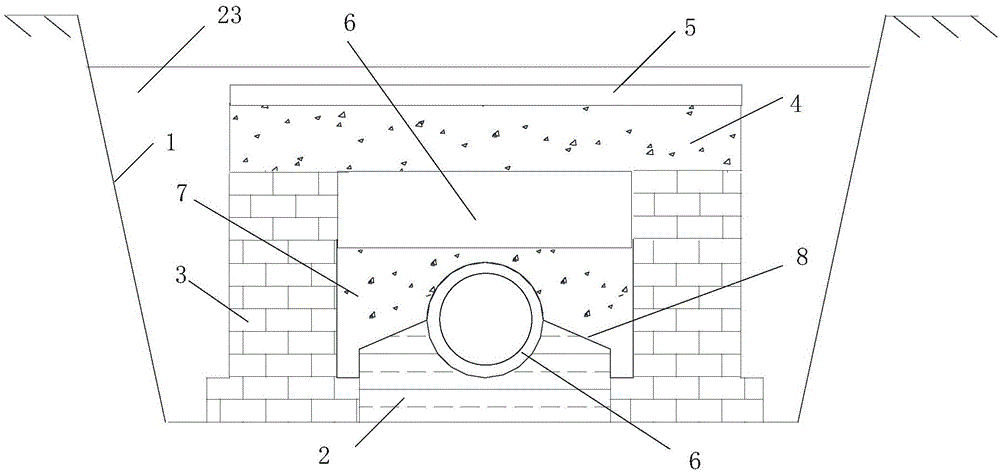

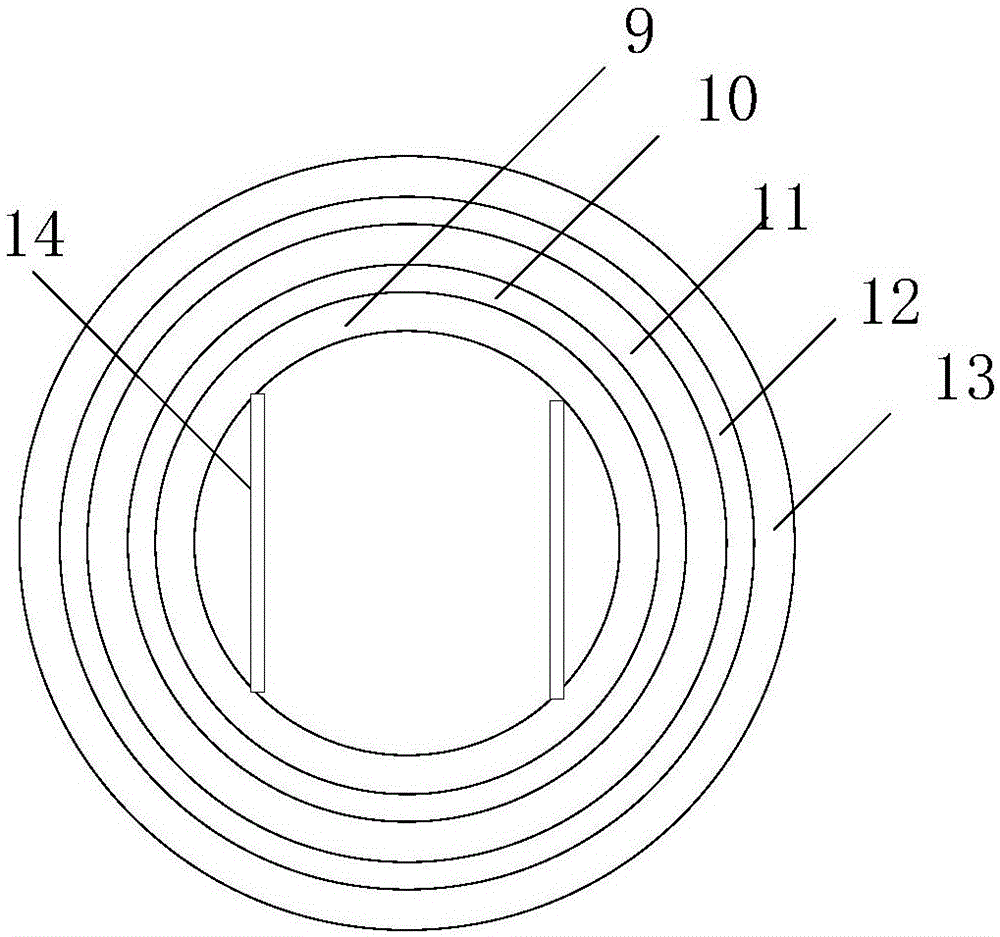

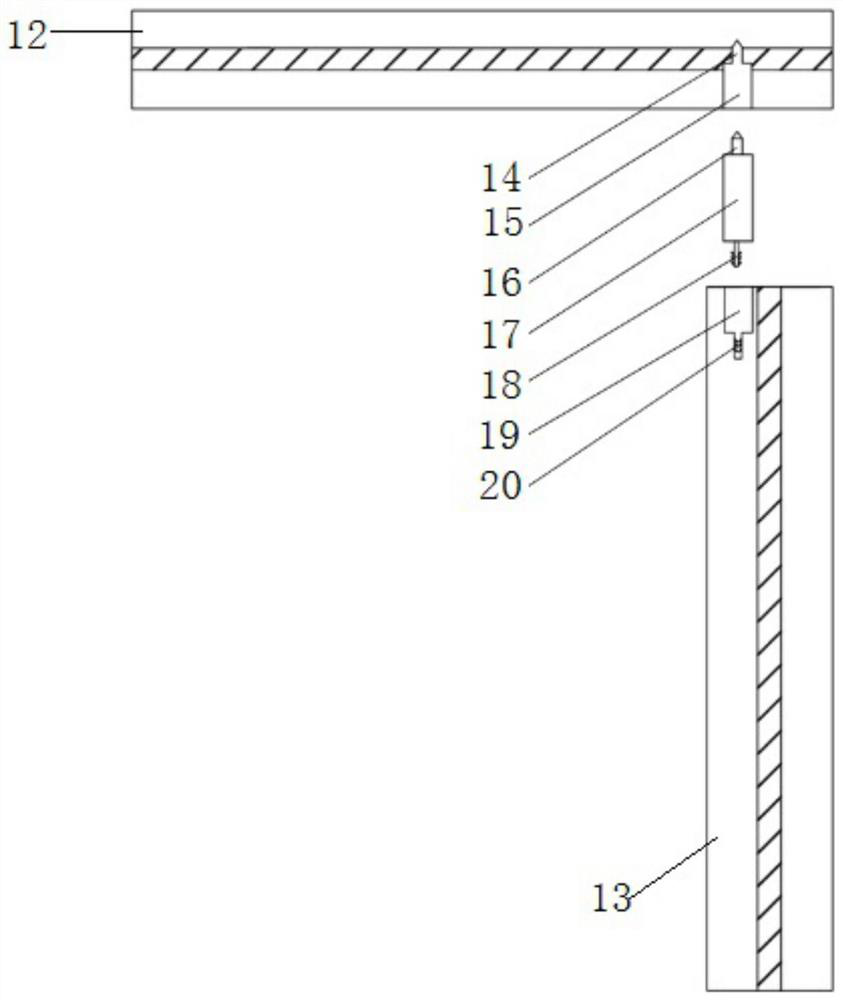

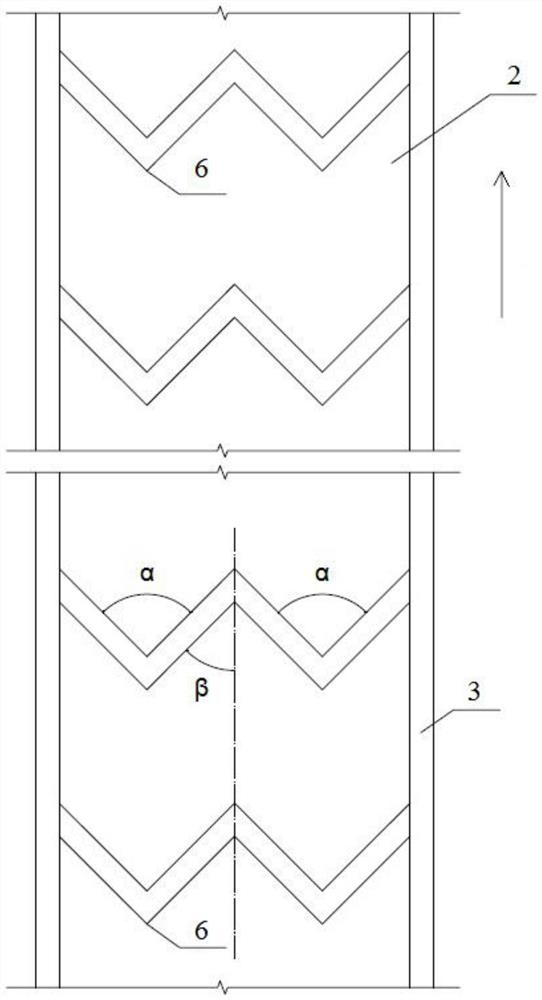

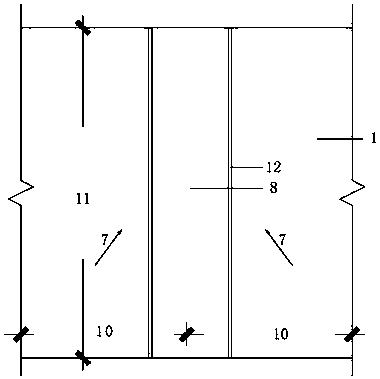

Road pipeline crossing node protection structure

ActiveCN105088916ASatisfy the articulation positioningAchieve protectionTemporary pavingsArchitectural engineeringStructural engineering

The invention relates to a road pipeline crossing node protection structure, comprising a road pre-embedded groove, which is internally provided with a bearing base course. The road pipeline crossing node protection structure is characterized in that symmetric support assemblies are arranged at two sides of the bearing base course, and corresponding pipeline through holes are formed in the support assemblies; a cover plate is connected to the top ends of the support assemblies and is provided with a separation assembly; the bearing base course is provided with pipeline reinforcing assemblies crossed up and down in a non-horizontal manner, two ends of pipeline reinforcing assembly at the upper layer are connected with the pipeline through holes, and a fill layer is distributed between the pipeline reinforcing assemblies. Therefore, the connection positioning of the pipeline reinforcing assembly at the upper layer can be guaranteed, and crossed pipelines can be protected. Furthermore, external stress from all directions can be absorbed effectively, corrosion caused by underwater infiltration can be prevented, and road pipeline pre-embedding with crossed pipeline layout can be available.

Owner:苏州同尚工程设计咨询有限公司

Method for cultivating vallisneria natans seedlings

ActiveCN103053310BImprove survival rateReduce pollutionCultivating equipmentsHorticulture methodsVallisneria natansRhizome

The invention discloses a method for cultivating bitter weed seedlings, which comprises the following steps: digging the seedbed to a depth of 8 to 10 centimeters, breaking the soil blocks, adding 0.3 to 0.5 kilograms of humus per square meter of the seedbed, stirring evenly, and then feeding the seedlings Add water to the field, and add bleaching powder to the water for disinfection; choose bitter grass with a plant height of 15 to 20 cm as seedlings, put them in the disinfection pool and soak them for 6 to 10 minutes; The seedlings are one-pot, spray the hormone combination solution on the seedbed, and then cover the seedlings with a film; control the water temperature in the nursery field to be 15 to 30 degrees, and when the seedlings are transplanted into the nursery field for 48 to 52 days, the new growth formed by the rhizomes will form. The bitter grass seedlings will grow to a plant height of 10 cm; remove the film covering the bitter grass seedlings, add water to the seedbed, keep it for 9 to 11 days, and move the seedlings out of the nursery field to obtain the bitter grass seedlings. The method of the invention breaks the season limitation of Erytheria galerica planting, and overcomes the disadvantages of high cost, long period and high operation requirements in its tissue culture technology.

Owner:CHENGDU HUADU AGRI DEV

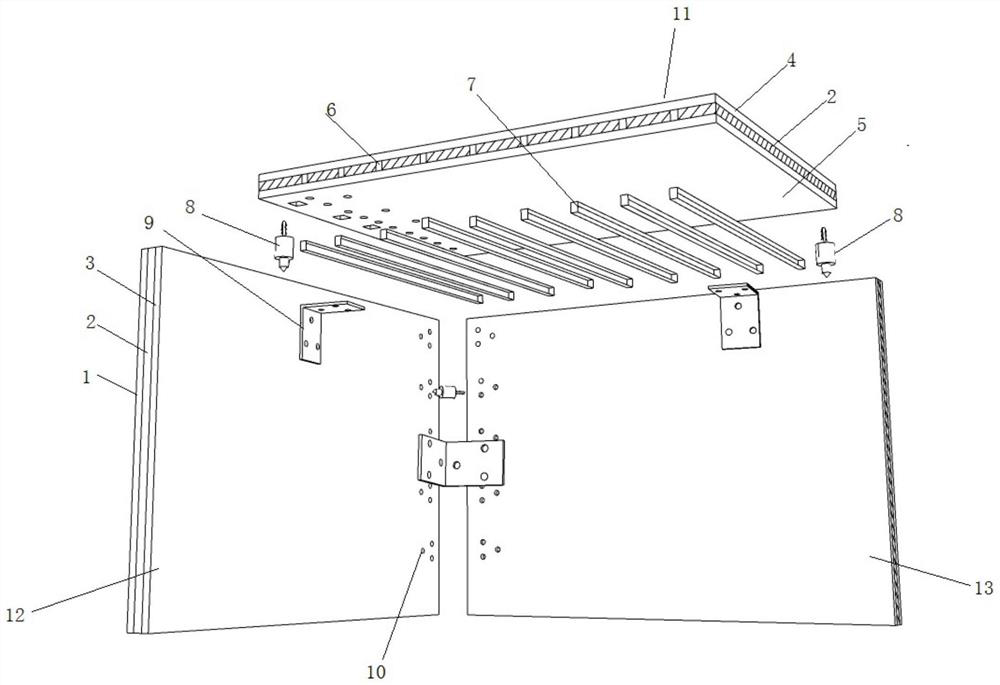

Energy saving integrated engineering bamboo assembly building system with low cost structure

PendingCN111733967AIncrease profitImprove machining accuracyBuilding constructionsArchitectural engineeringWall plate

The invention discloses an energy saving integrated engineering bamboo assembly building system with a low cost structure. The energy saving integrated engineering bamboo assembly building system withthe low cost structure comprises a main wall board, a side wall board and a building roof board; the main wall board and the side wall board are all bonded by inner side engineering bamboo boards, straw boards and outer side engineering bamboo boards in sequence; the building roof board includes an upper side engineering bamboo board, the straw boards, a lower side engineering bamboo board and stiffening ribs; the multiple straw boards are bonded between the upper side engineering bamboo board and the lower side engineering bamboo board, rib slots are formed between the adjacent straw boards,and each rib slot is bonded with the stiffening ribs; and the main wall board and the building roof board are connected through metal connectors and L-shaped angle steel connectors, the side wall board and the building roof board are connected through the metal connectors and the L-shaped angle steel connectors, and the main wall board and the side wall board are connected through the metal connectors and the L-shaped angle steel connectors. The energy saving integrated engineering bamboo assembly building system with the low cost structure simplifies the complex connection mode, the field assembly is simple and fast, the construction efficiency is effectively improved, and the advantages of factory reservation system, stable quality, small space occupation, convenient transportation, lowtransportation cost, environmental protection and the like are realized.

Owner:南京森工生物质材料研究院有限公司

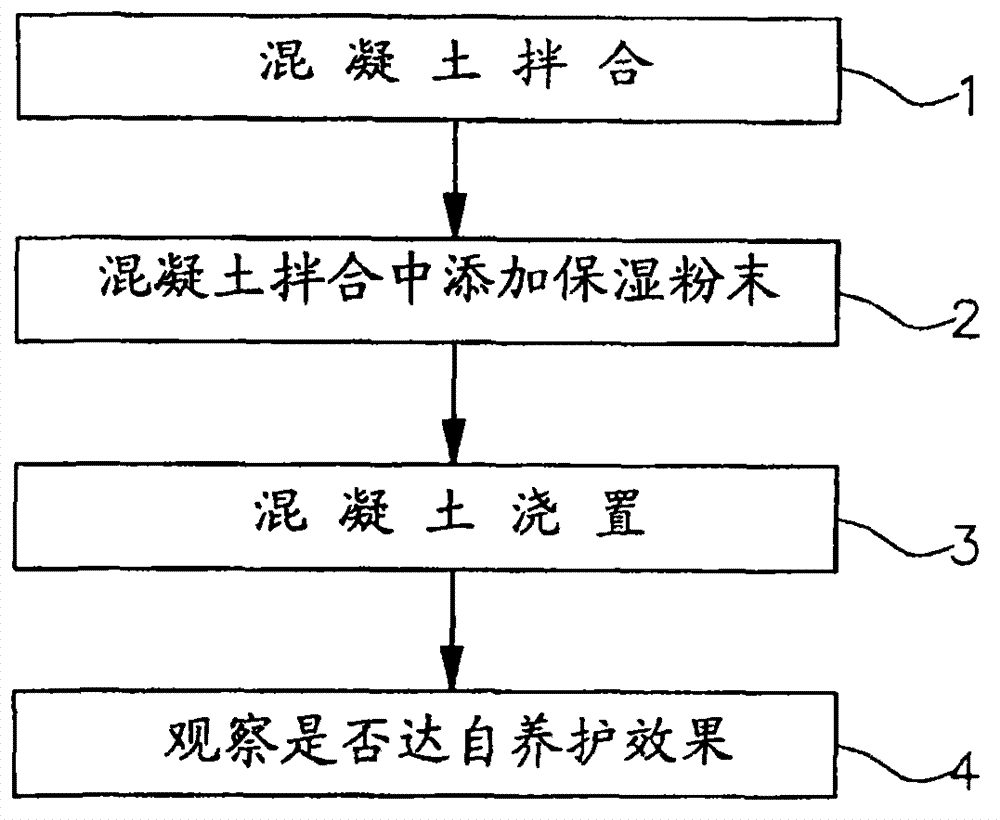

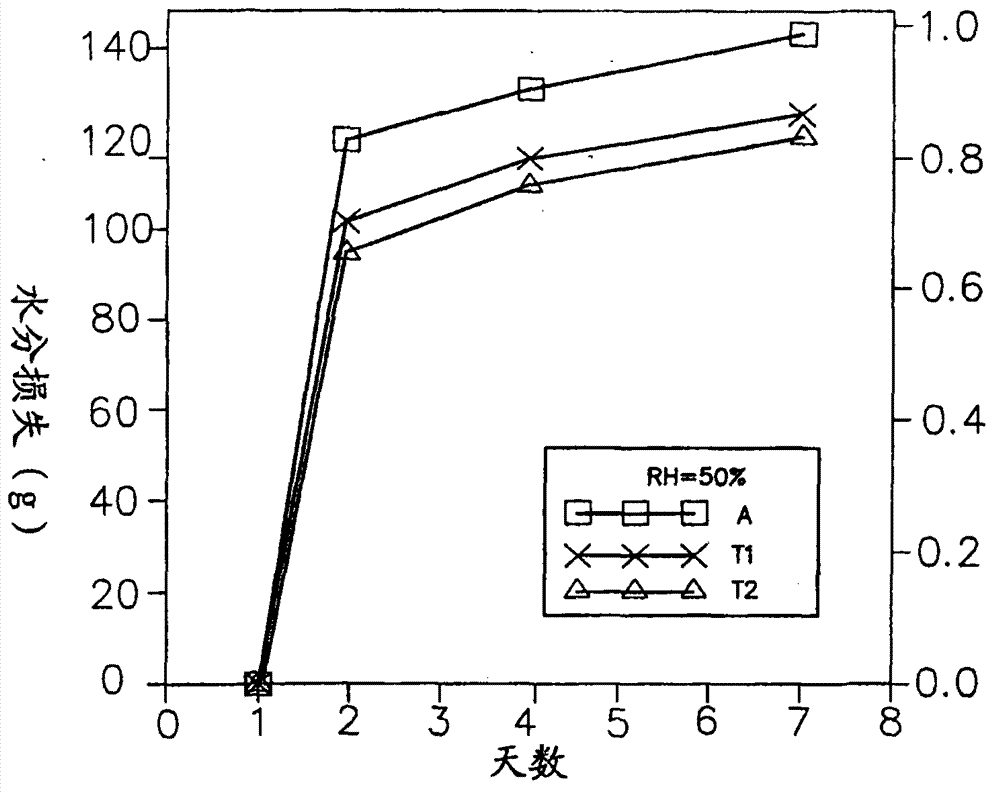

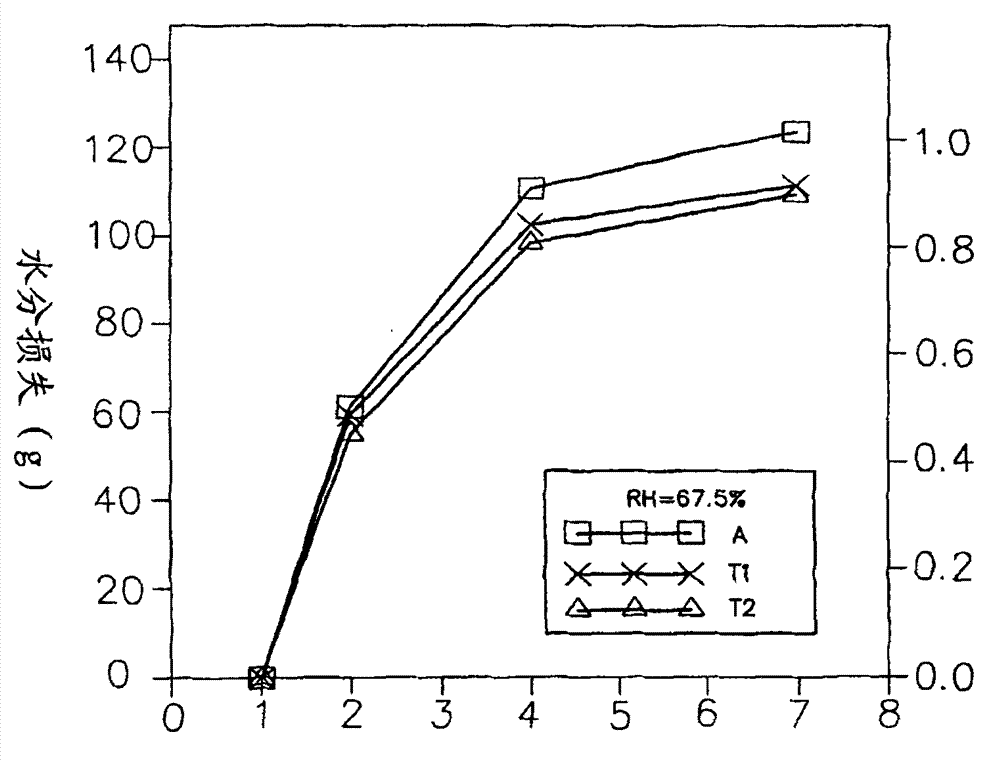

Self-maintenance concrete

InactiveCN102731013AHigh compressive strengthConservation economySelf maintenanceCompressive strength

The invention relates to self-maintenance concrete. High-performance moisture retention powder is added to mixed concrete, the amount of the moisture retention powder is 0.5-5wt% of cement in the concrete, and the moisture retention powder which can absorb a water steam in air and release water to the concrete enables the self-maintenance efficacy of the concrete to be reached without extra water or any external maintenance after watering the concrete. The self-maintenance concrete can avoid the excess evapotranspiration of water on the surface of the concrete, and can solve known problems of incomplete cement hydration and concrete requirement unsatisfying caused by failure concrete maintenance. The self-maintenance concrete allows the high-performance moisture retention powder to be added to the mixed concrete, and the moisture retention powder which can absorb the water steam in the air and release water to the concrete enables the self-maintenance efficacy of the concrete to be reached without extra water or any external maintenance after watering the concrete; and compared with self-filling concrete subjected to wet maintenance, the self-maintenance concrete of the invention has the advantages of no need of long-time manpower wet maintenance, manpower cost saving, and good compressive strength.

Owner:赵文成

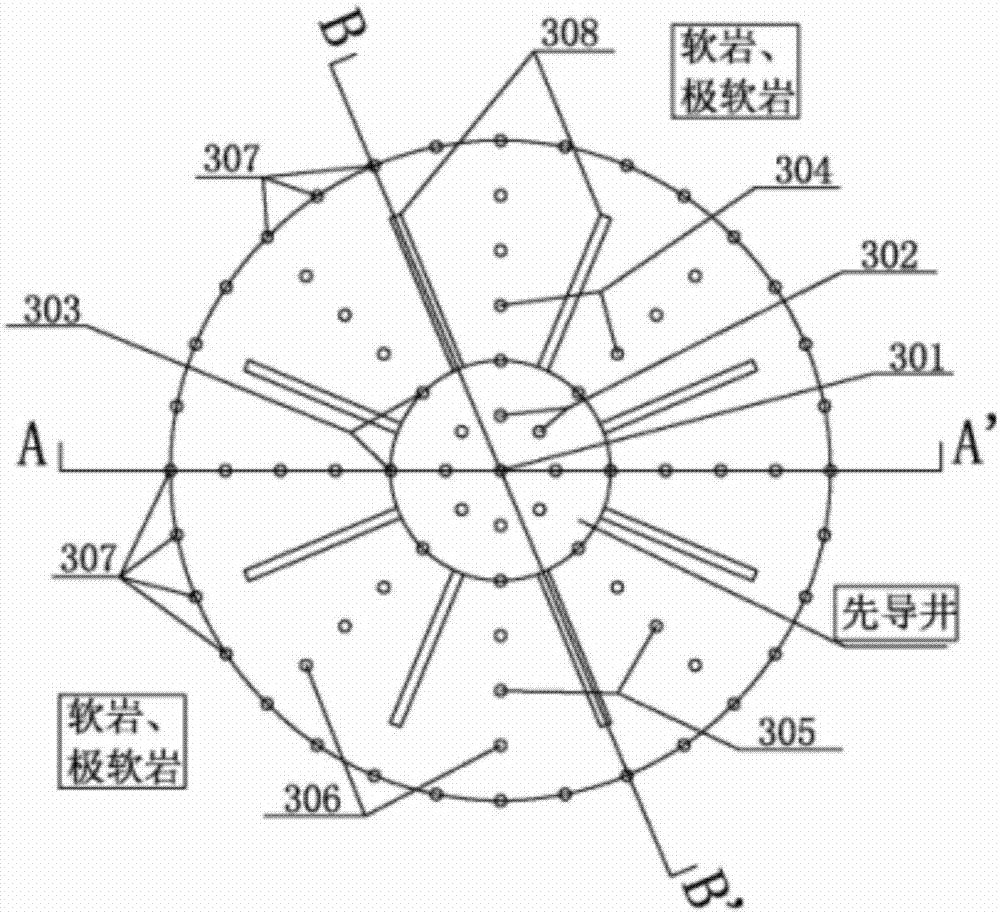

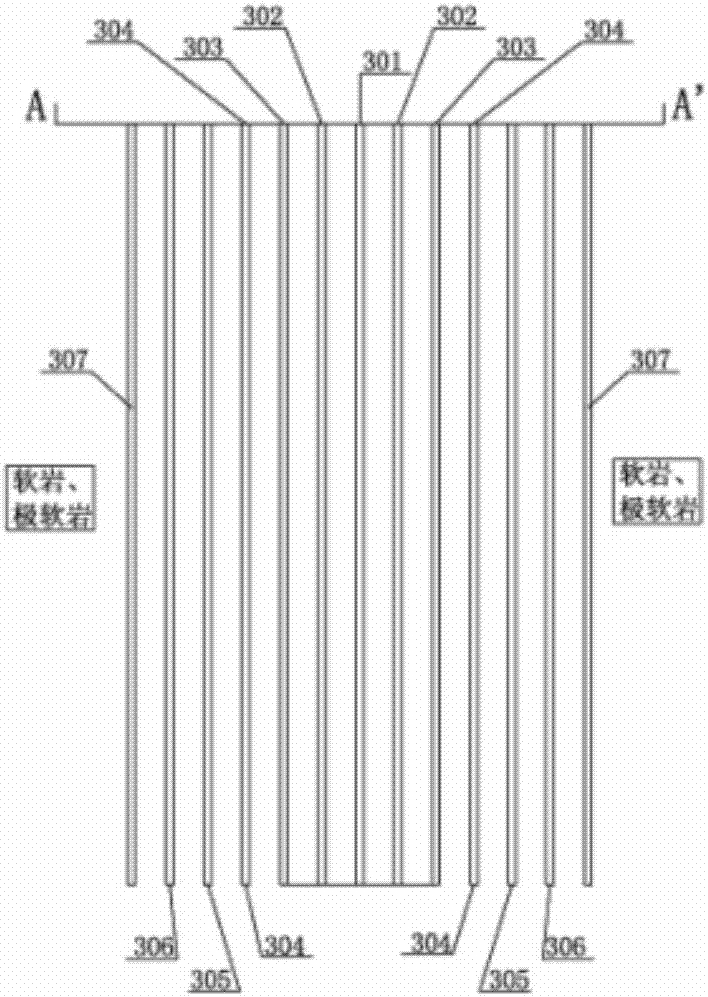

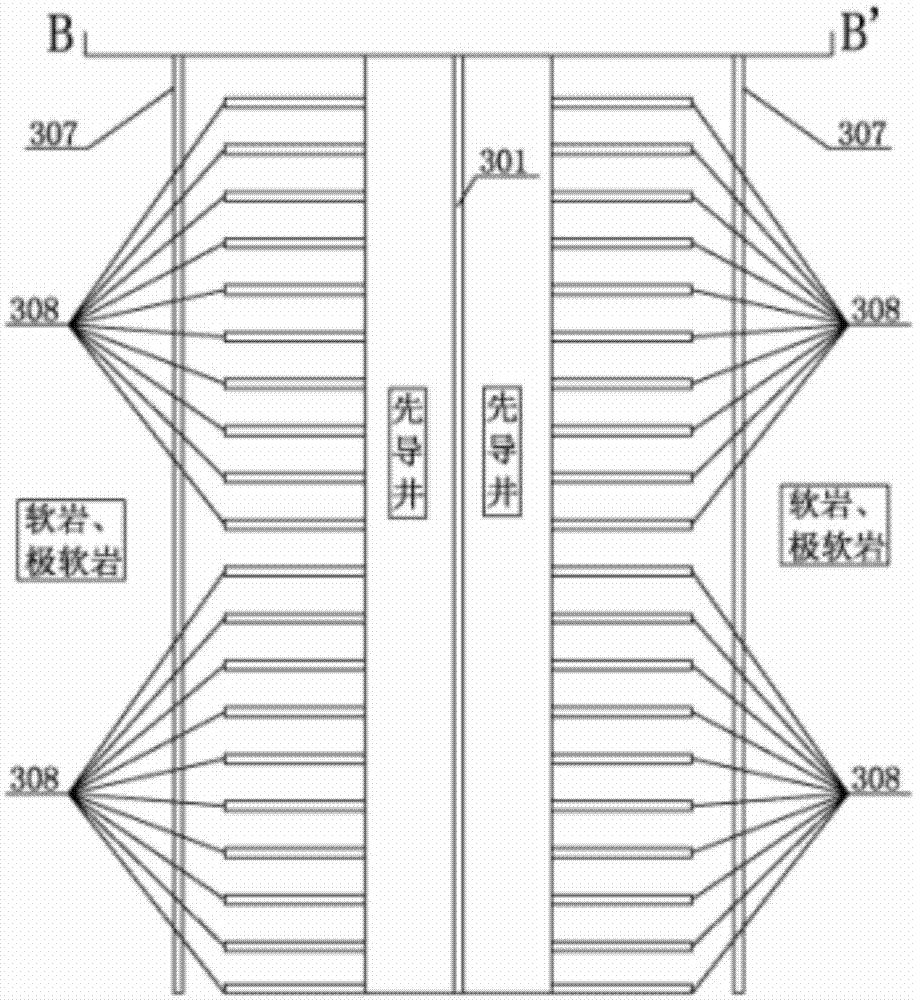

Method for smooth blasting excavation of large-diameter surge shaft and long-footage pilot well in soft-rock and extremely-soft-rock area

The invention provides a method for smooth blasting excavation of a large-diameter surge shaft and a long-footage pilot well in a soft-rock and extremely-soft-rock area. The method comprises the steps of (A) excavation of the long-footage pilot well and (B) excavation of the surge shaft. (A) comprises the steps that I, blast holes of the pilot well are distributed; II, detonation is conducted on the pilot well; III, deslagging is conducted on the pilot well; and IV, a small step that horizontal blast holes are distributed is conducted. (B) comprises the steps that V, blast holes of a surge shaft are distributed; VI, surge hole detonation is conducted; and VII, a small step of surge shaft deslagging is conducted. Through a mode that the pilot well and the blast hole positions of the surge shaft are arranged, the detonating order is set, the hole depth, the hole diameter and the blasting strength of each blast hole is designed, the problems of peeling off, cracking and chip off-falling of a surrounding rock and a concrete lining caused by previous repeated blasting and excavation are solved, the smooth blasting effect is achieved, one-time excavation forming is achieved, and deslagging from top to bottom is achieved; and the construction mode is improved, the working efficiency is improved, the tunneling schedule is effectively guaranteed, the construction period is shortened, and further the safety of the personnel and equipment are guaranteed.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Method for cultivating vallisneria natans seedlings

ActiveCN103053310AImprove survival rateReduce pollutionCultivating equipmentsHorticulture methodsVallisneria natansHumus

The invention discloses a method for cultivating vallisneria natans seedlings. The method includes steps of digging a seedling bed with the depth ranging from 8 centimeters to 10 centimeters, smashing soil blocks, adding from 0.3 to 0.5 kilogram of humus soil to each square meter of seeding bed, uniformly stirring the humus soil in the seedling bed, adding water into a seedling culture field and adding bleaching powder into the water for disinfection; selecting vallisneria natans with plant heights ranging from 15 centimeters to 20 centimeters as annual seedlings, and placing and soaking the annual seedlings in a disinfection tank for 6 to 10 minutes; transplanting the annual seedlings on the seedling bed, dividing each three to five annual seedlings as a stump, spraying combination hormone liquid on the seedling bed and covering a thin film on the annular seedlings; controlling the temperature of the water of the seedling culture field to range from 15 DEG C to 30 DEG C; and removing the thin film covering the vallisneria natans seedlings, filling water into the seedling bed, keeping the seedlings in the seedling bed for 9 to 11 days and shifting the seedlings out of the seedling culture field to obtain the vallisneria natans seedlings. After the annual seedlings are transplanted in the seedling culture field for 48 to 52 days, plant heights of new vallisneria natans seedlings grown on underground stems can reach 10 centimeters. The method has the advantages that seasonal limitation on plantation of the vallisneria natans can be broken through, and shortcomings of high cost, long period, high operational requirements and the like of a tissue culture technology for the vallisneria natans can be overcome.

Owner:CHENGDU HUADU AGRI DEV

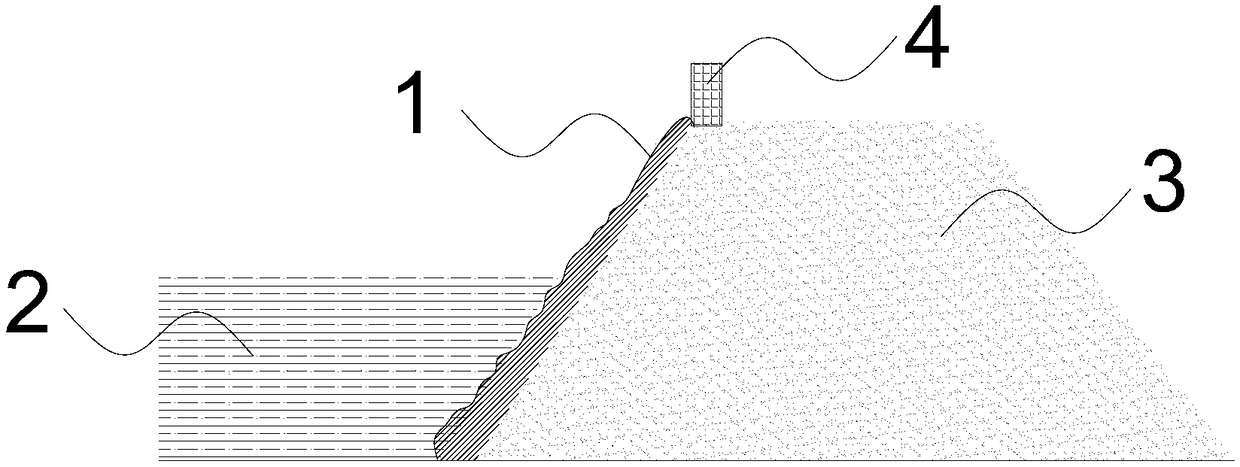

Large-section flood discharge ditch for mountainous terrain and construction method thereof

ActiveCN112031119AAffect securityImprove construction efficiencySewer pipelinesMountainous terrainWater flow

The invention relates to the technical field of mountainous flood discharge, and particularly relates to a large-section flood discharge ditch for mountainous terrain and a construction method thereof. The large-section flood discharge ditch for the mountainous terrain comprises a flood discharge ditch body, wherein the flood discharge ditch body comprises a flood discharge ditch bottom plate andflood discharge ditch side walls arranged on the two sides of the flood discharge ditch bottom plate, and a water drop energy dissipation structure is arranged on the flood discharge ditch bottom plate. The construction method of the large-section flood discharge ditch for the mountainous terrain comprises the following steps that 1, the flood discharge ditch body is constructed, wherein the flooddischarge ditch bottom plate and the flood discharge ditch side walls are constructed; and 2, according to the plane turning angle and the longitudinal slope gradient of the flood discharge ditch body, the water drop energy dissipation structure is correspondingly constructed on the flood discharge ditch bottom plate; when water flow flows through a channel formed by the flood discharge ditch bottom plate and the flood discharge ditch side walls, the energy dissipation effect of the water drop energy dissipation structure is utilized to reduce the kinetic energy of the water flow, so that theimpact effect of the water flow on the flood discharge ditch body and a downstream reservoir area is reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

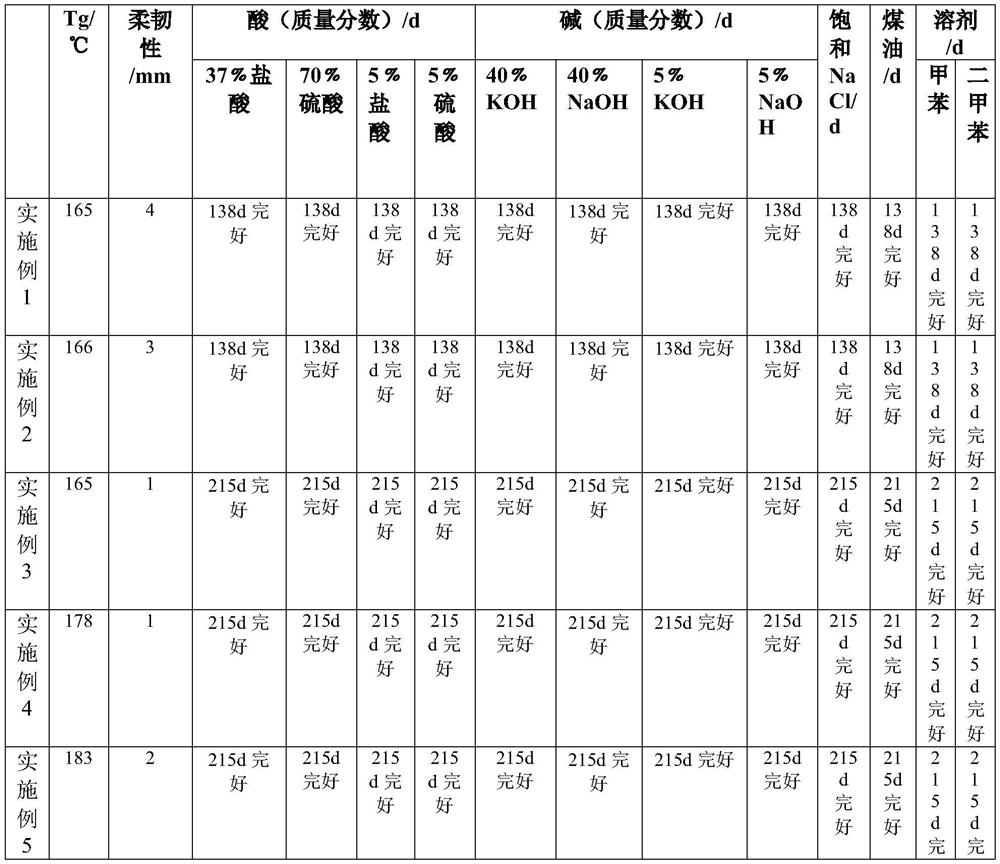

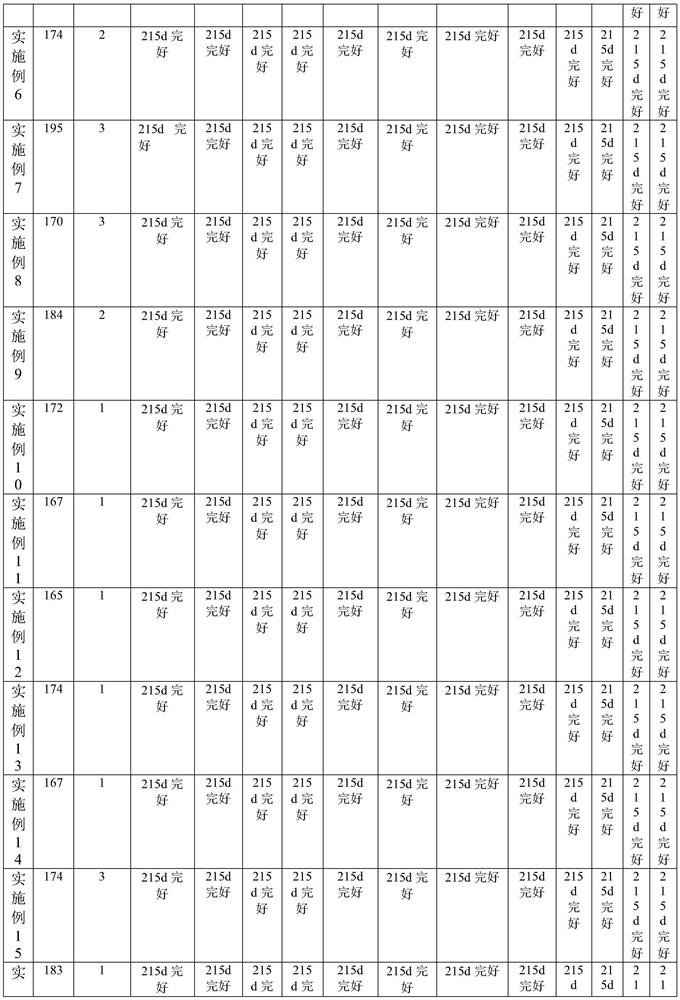

A kind of high glass transition temperature water-based solvent-free polyurea coating material and preparation method thereof

ActiveCN111087905BHigh glass transition temperatureGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemical industryPolymer science

The invention belongs to the field of chemical industry, in particular to a high glass transition temperature water-based solvent-free polyurea coating material and a preparation method thereof. In particular, it relates to a water-based solvent-free polyurea coating material used in the fields of acid and alkali resistance and chemical medium resistance and a preparation method thereof. The coating is composed of oily component A and water-based component B in a mass ratio of (0.5-5): 1; wherein, oily component A is an active ingredient, a pigment filler and an auxiliary agent; the active ingredient is oily Isocyanates and phosphates. The water-based solvent-free polyurea coating involved in the present invention has a higher glass transition temperature, better flexibility and excellent corrosion resistance, and has excellent chemical medium resistance such as acid and alkali resistance, oil resistance, solvent resistance, etc., especially in strong acid resistance. , strong alkali, excellent performance. It can be used in relatively harsh corrosive environments to improve the service life of equipment, especially suitable for chemical anti-corrosion fields, such as corrosion protection in chemical plant sour gas areas, equipment linings, and concentrated waste pools.

Owner:SHENYANG RES INST OF CHEM IND

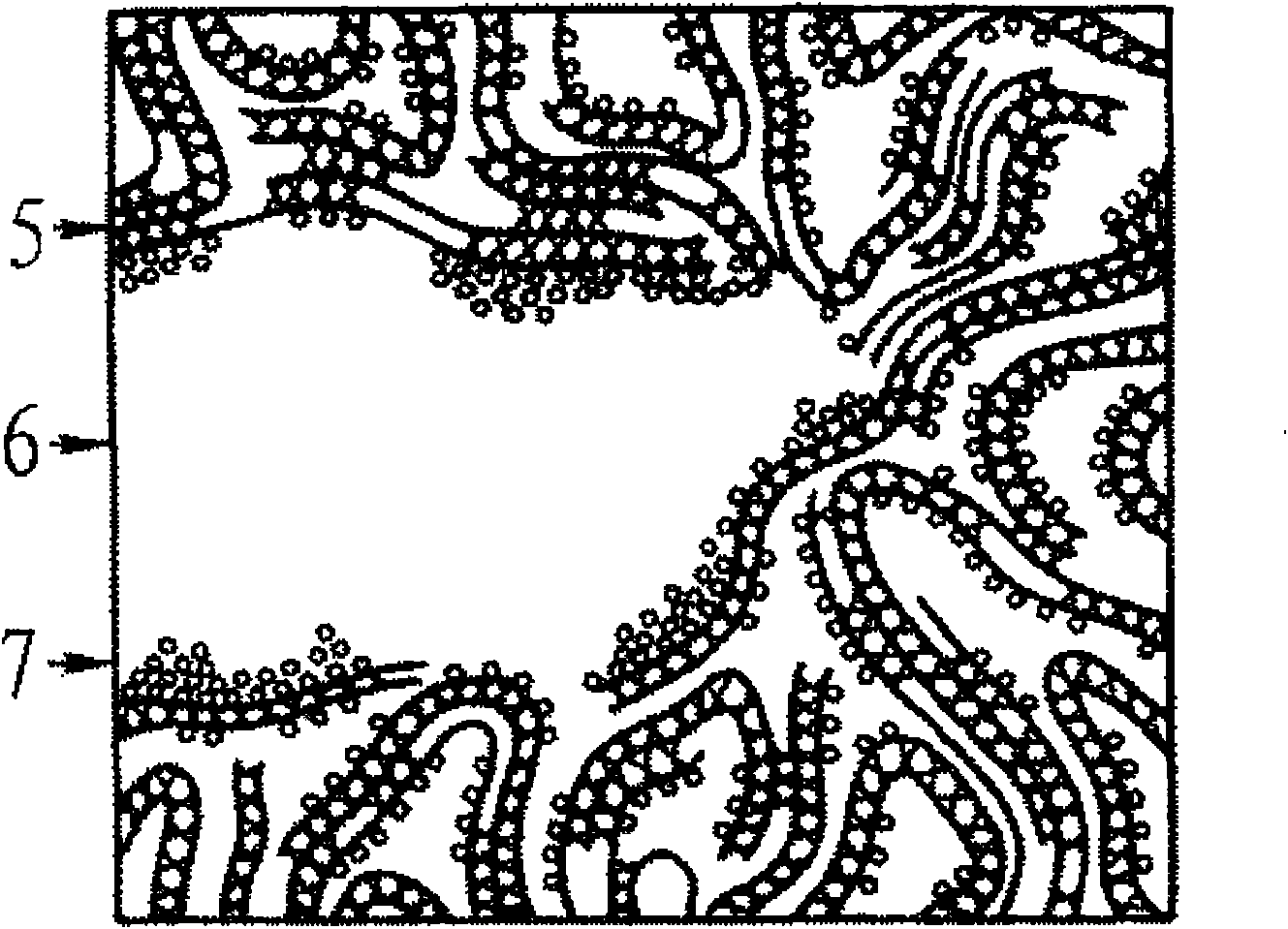

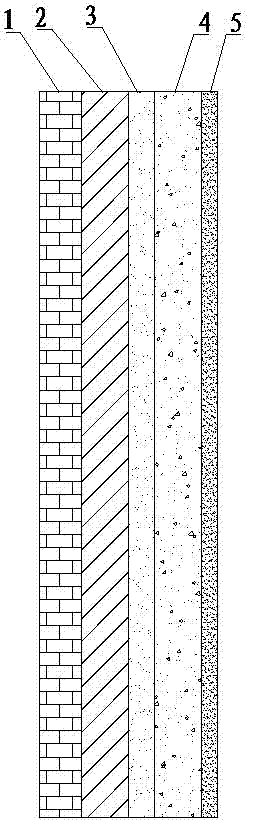

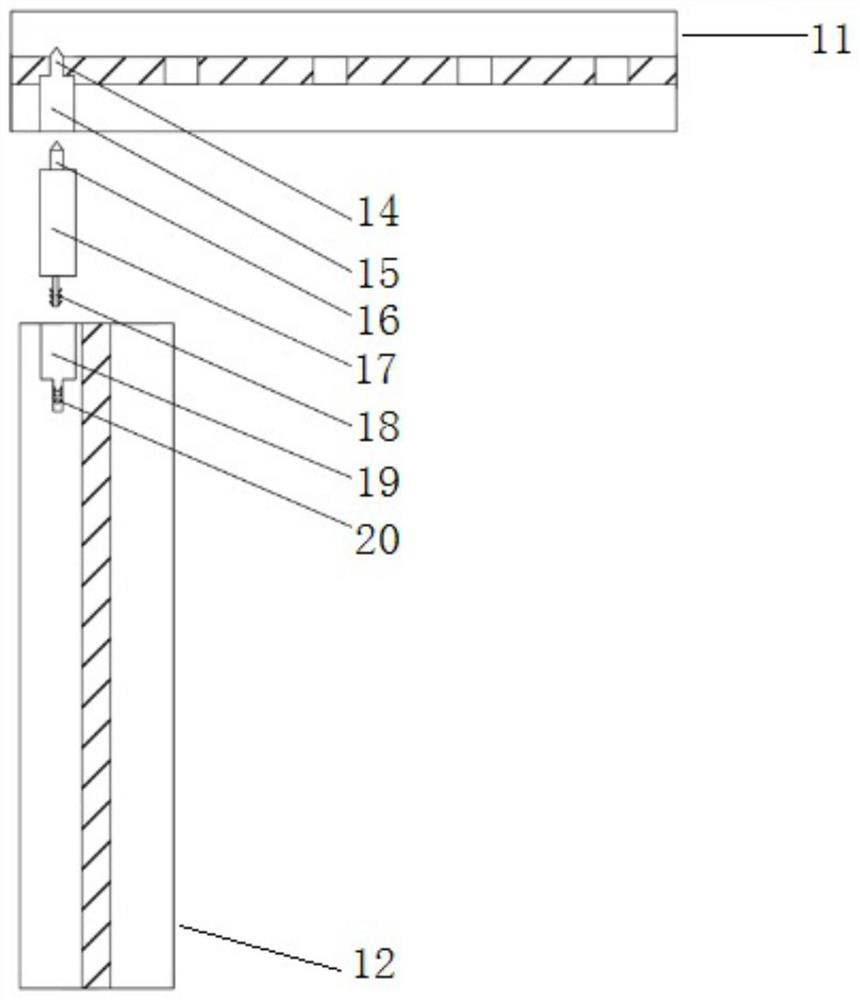

Structure of external wall facing layer

PendingCN108301577ASimple construction methodReduce the cost of improvementCovering/liningsStructural unitEngineering

The invention relates to a structure of an external wall facing layer. The structure of the external wall facing layer is characterized by comprising a plurality of structural units, wherein each structural unit comprises a biological nano-film layer, a paint coating layer, an air interlayer layer, a wire mesh layer, an insulating layer, an external wall of a building, a waterproof material layerand waterproof mortar, wherein structures on both sides of each structural unit are sequentially provided with the insulating layer, the wire mesh layer, the air interlayer layer, the paint coating layer and the biological nano-film layer from the exterior wall of the building to the outside; the structure of the middle part of each structural unit is sequentially provided with the insulating layer, the wire mesh layer, the air interlayer layer and the waterproof material layer from the exterior wall of the building to the outside; the paint coating is used for forming a slope to a waterproofmaterial layer from thick to thin; and the two sides of each waterproof material layer are filled with the waterproof mortar. The construction method is simple, convenient and low in improvement cost;the scope of application is wide. The dust removal effect of the building is good, the maintenance cost of the building is reduced, the service life of the outer wall is prolonged, and the structureof the external wall facing layer can adapt to various building outside facade practices.

Owner:NANCHANG UNIV

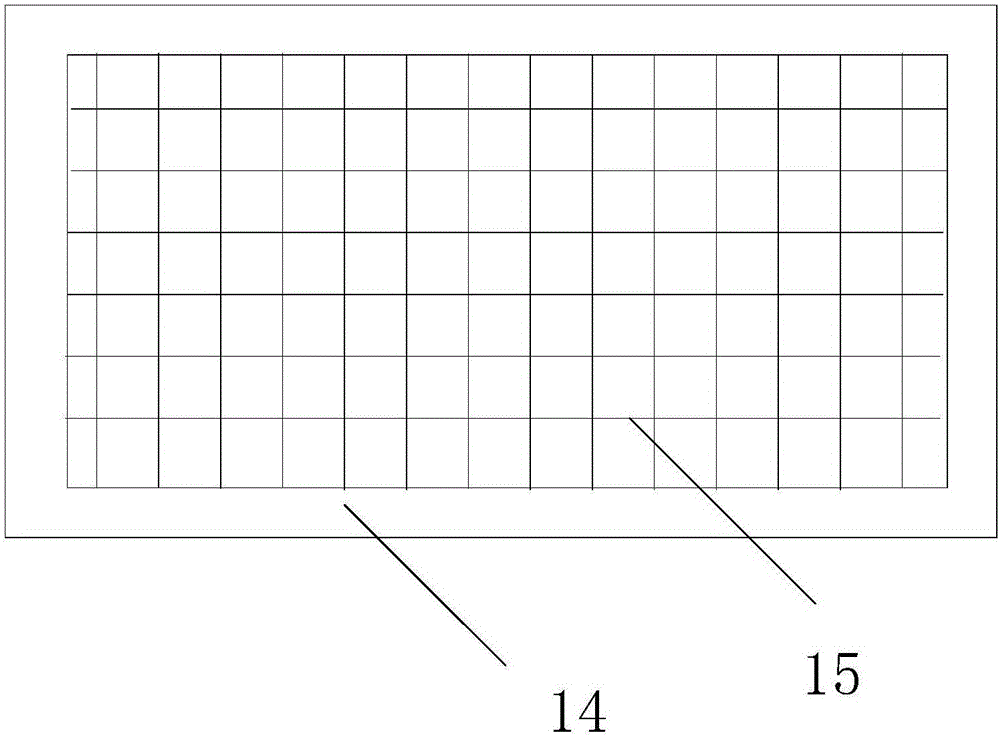

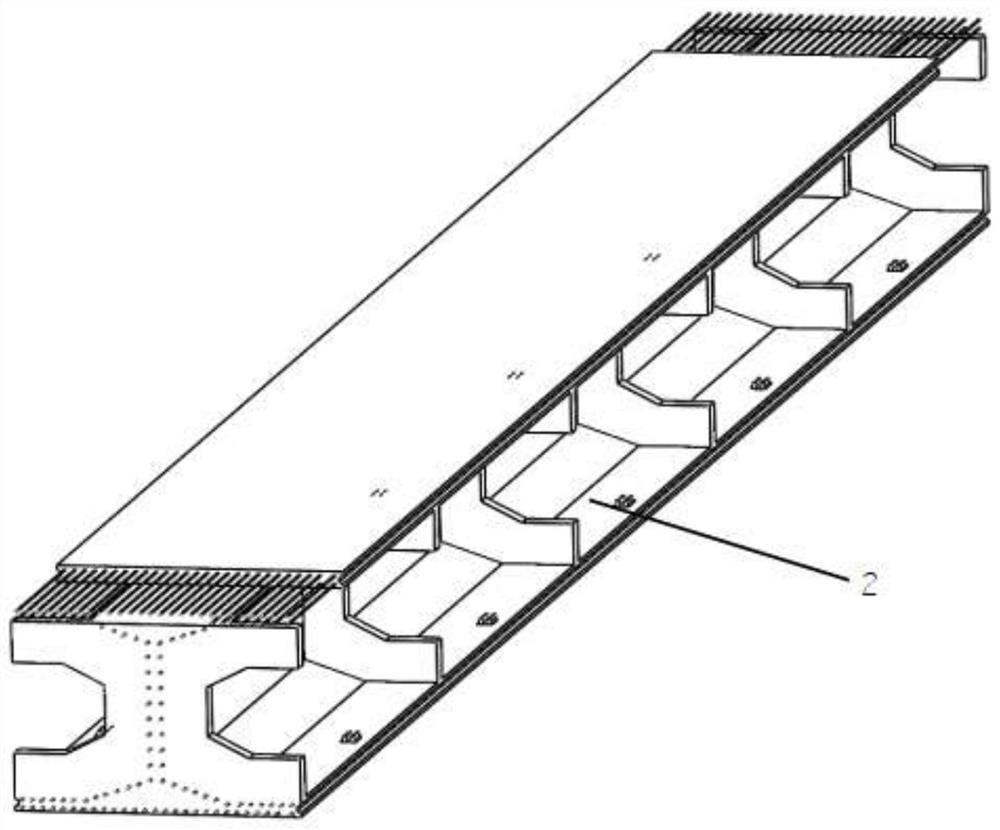

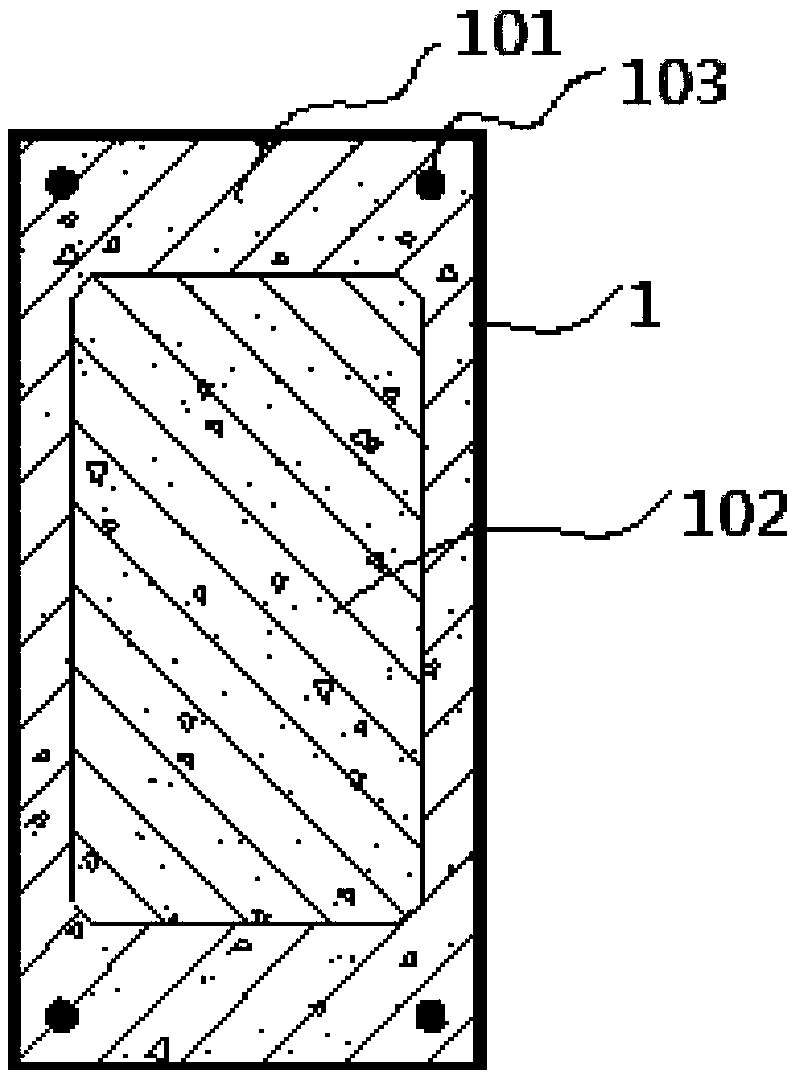

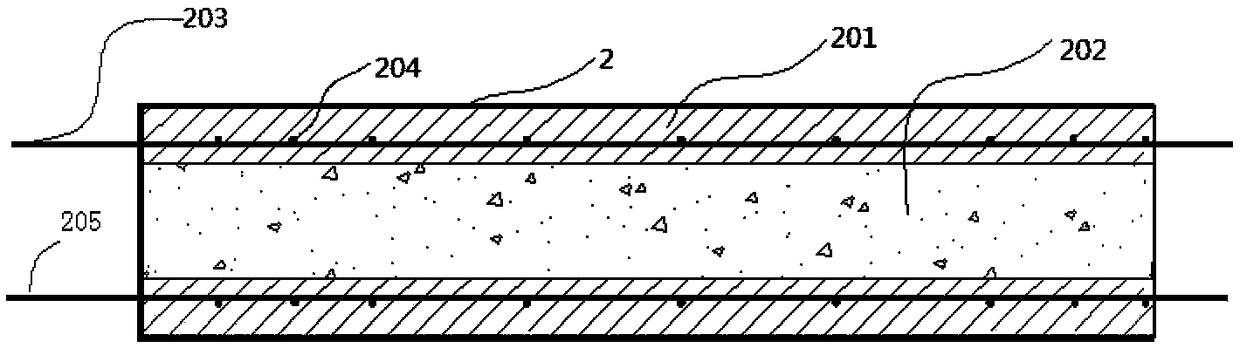

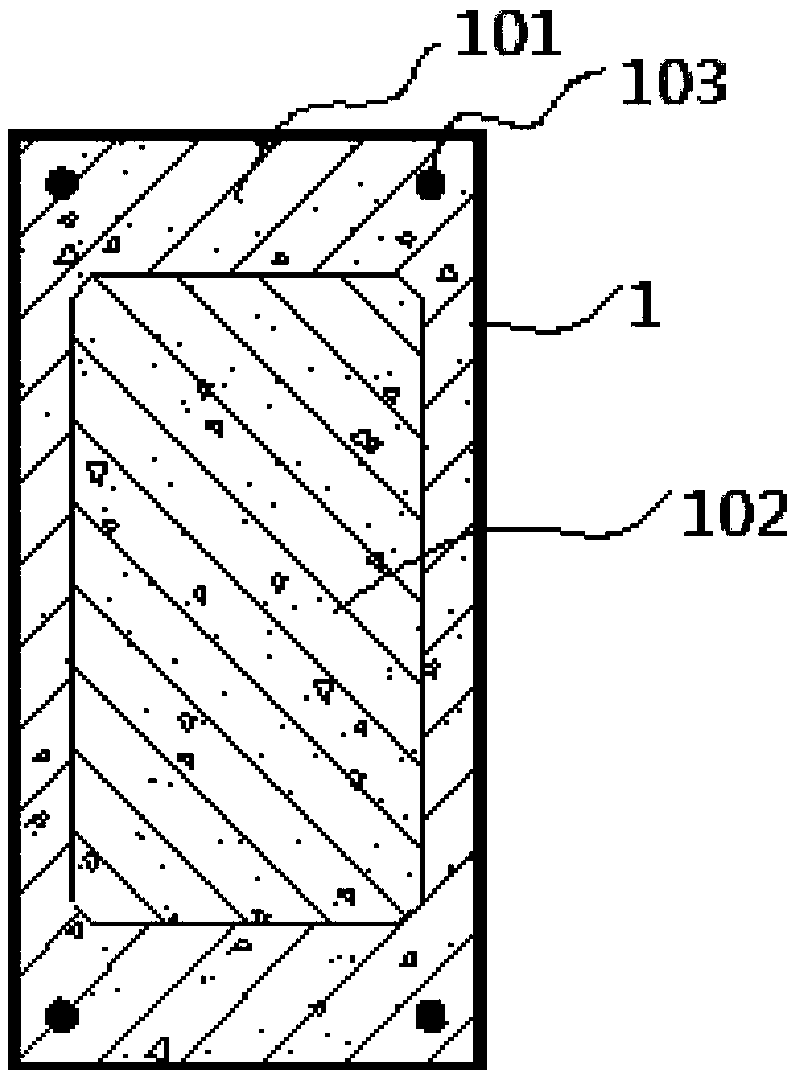

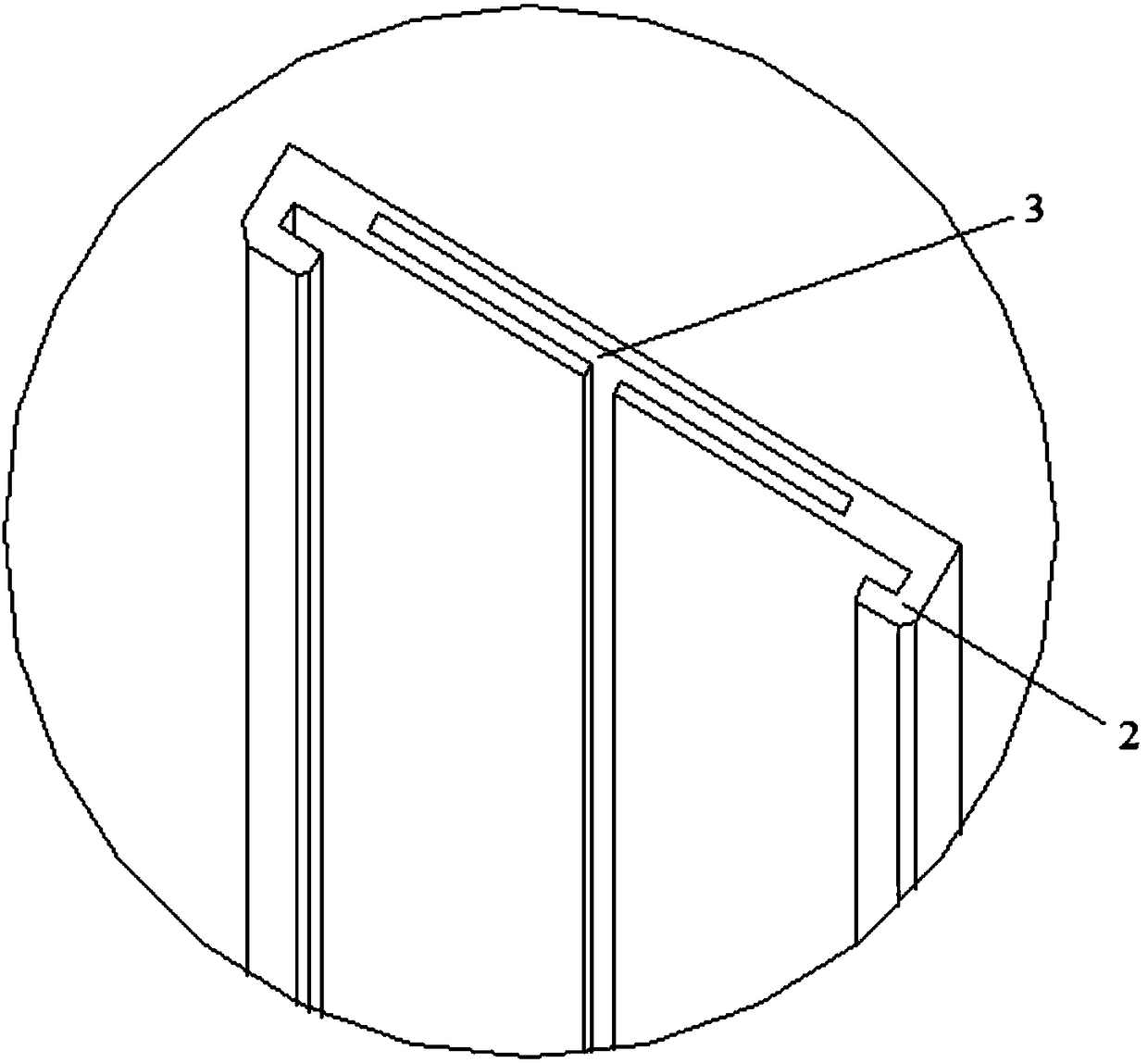

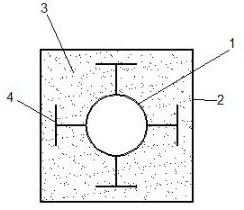

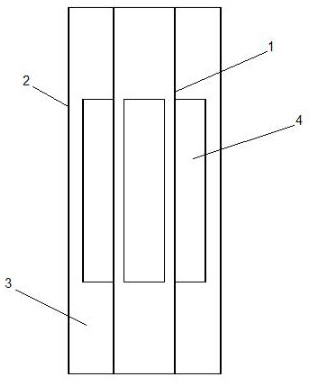

Square-sleeve-round steel tube ultra-high performance concrete column with T-shaped section stiffening ribs

PendingCN113431262AImprove liquidityImprove the compressive capacityStrutsPillarsUltimate tensile strengthSteel tube

The invention discloses a square-sleeve-round steel tube ultra-high performance concrete column with T-shaped section stiffening ribs. The square-sleeve-round steel tube ultra-high performance concrete column is characterized by comprising an inner steel tube 1, an outer steel tube 2, the T-shaped stiffening ribs 3 and ultra-high performance concrete 4. The inner steel tube and the outer steel tube are square-sleeve-round thin-wall steel tubes and are concentrically arranged, the ultra-high performance concrete is added into an interlayer, and the T-shaped ribs are welded to the inner steel tube so as to be arranged in the concrete. Although the ultra-high performance concrete is high in strength, the brittleness is large, and the T-shaped ribs are arranged to assist the square outer steel tube in better restraining the concrete. The member improves the flexural capacity of the concrete filled steel tube column under the bias pressure condition, so that the ductility of the member is improved, and the member has the advantages of reasonable stress, clear force transmission, high construction speed and the like, and is more suitable for being used in practical engineering.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com