Non-pressed pipeline reinforcing structure for road surface and construction method for non-pressed pipeline reinforcing structure

A technology for pipelines and pavements, which is applied in the field of non-compressed reinforced pipeline structures and their construction, can solve problems such as pipeline compression, and achieve the effects of satisfying firmness, good deformation characteristics, and convenient construction and manufacturing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

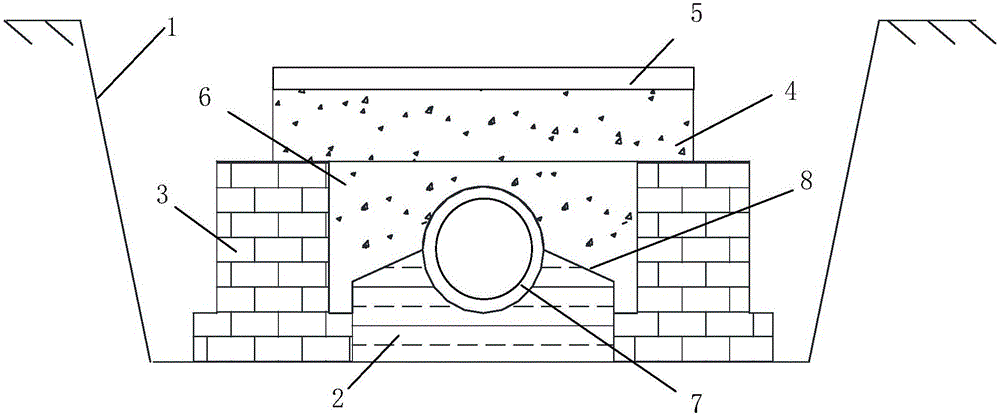

[0084] The non-pressure reinforced pipeline structure suitable for the road surface includes a road surface embedded groove 1, and a base layer 2 is arranged in the road surface embedded groove 1, and its special feature is that there are symmetrically distributed The shield assembly 3 is connected with a cover plate 4 at the top end of the shield assembly 3 . Meanwhile, a partition assembly 5 is provided on the cover plate 4 . Moreover, a filling layer 6 is distributed in the protection space, and a pipeline reinforcement component 7 is also arranged on the base layer 2 .

[0085] Further, the shielding component 3 used includes a bottom base material layer, on which a lateral reinforcing wall is arranged. Considering the convenience of actual construction, both the bottom base material layer and the lateral reinforcement wall are constructed of brick walls, and the width of the bottom base material layer is greater than that of the lateral reinforcement wall.

[0086] At t...

Embodiment 2

[0091] The non-pressure reinforced pipeline structure suitable for the road surface includes a road surface embedded groove 1, and a base layer 2 is arranged in the road surface embedded groove 1, and its special feature is that there are symmetrically distributed Blocking component 3. A cover plate 4 is connected to the top of the shielding assembly 3 . Meanwhile, a partition assembly 5 is provided on the cover plate 4 . Moreover, a filling layer 6 is distributed in the protection space, and a pipeline reinforcement component 7 is also arranged on the base layer 2 .

[0092] Further, the shielding component 3 used includes a bottom base material layer, on which a lateral reinforcing wall is arranged. Considering the convenience of actual construction, both the bottom base material layer and the lateral reinforcement wall are constructed of brick walls, and the width of the bottom base material layer is greater than that of the lateral reinforcement wall.

[0093] At the sa...

Embodiment 3

[0098] The non-pressure reinforced pipeline structure suitable for the road surface includes a road surface embedded groove 1, and the road surface embedded groove 1 is provided with a base layer 2. The feature of the present invention is that: for both sides of the base layer 2, there are Symmetrically distributed occlusion components3. At the same time, a cover plate 4 is connected to the top of the shielding component 3 , and a partition component 5 is arranged on the cover plate 4 . Moreover, a filling layer 6 is distributed in the protection space, and a pipeline reinforcement component 7 is also arranged on the base layer 2 .

[0099] Further, the shielding component 3 used includes a bottom base material layer, on which a lateral reinforcing wall is arranged. Considering the convenience of actual construction, both the bottom base material layer and the lateral reinforcement wall are constructed of brick walls, and the width of the bottom base material layer is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com