Square-sleeve-round steel tube ultra-high performance concrete column with T-shaped section stiffening ribs

An ultra-high performance, concrete technology, applied in the field of concrete columns, can solve the problems of high brittleness, low ductility, brittle failure due to restraint, and achieve the effect of improving ductility, improving flexural bearing capacity and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

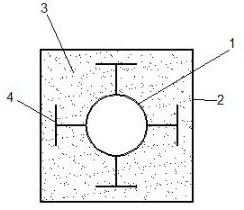

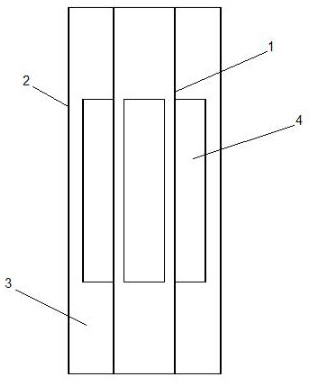

[0016] A steel pipe concrete column, as attached Figure 1-2 As shown, the inner steel pipe 1 is included, and the diameter and length of the outer steel pipe 2 are selected according to the construction needs. The inner steel pipe 1 is arranged at the axis of the outer steel pipe 2, and the T-shaped section stiffener 4 is welded on the inner steel pipe 1. The inner steel pipe 1 The space between the steel pipe 2 and the outer steel pipe 2 is filled with ultra-high performance concrete.

[0017] During construction, insert the steel pipe structure in the pit at the construction site, fix it, and then pour concrete into the gap between the outer steel pipe 2 and the inner steel pipe 1 from the upper port.

[0018] Preferably, the hollow ratio of the hollow interlayer concrete filled steel pipe column is 0.3-0.5.

[0019] Pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com