Large-section flood discharge ditch for mountainous terrain and construction method thereof

A construction method and large-section technology, applied in waterway systems, sewer pipe systems, water supply devices, etc., can solve threats to the safety of slopes and buildings on site, high-intensity impacts in downstream reservoir areas, steep mountains and large height differences, etc. problems, to achieve the effect of ensuring the quality and safety of flood discharge, low safety risk level, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

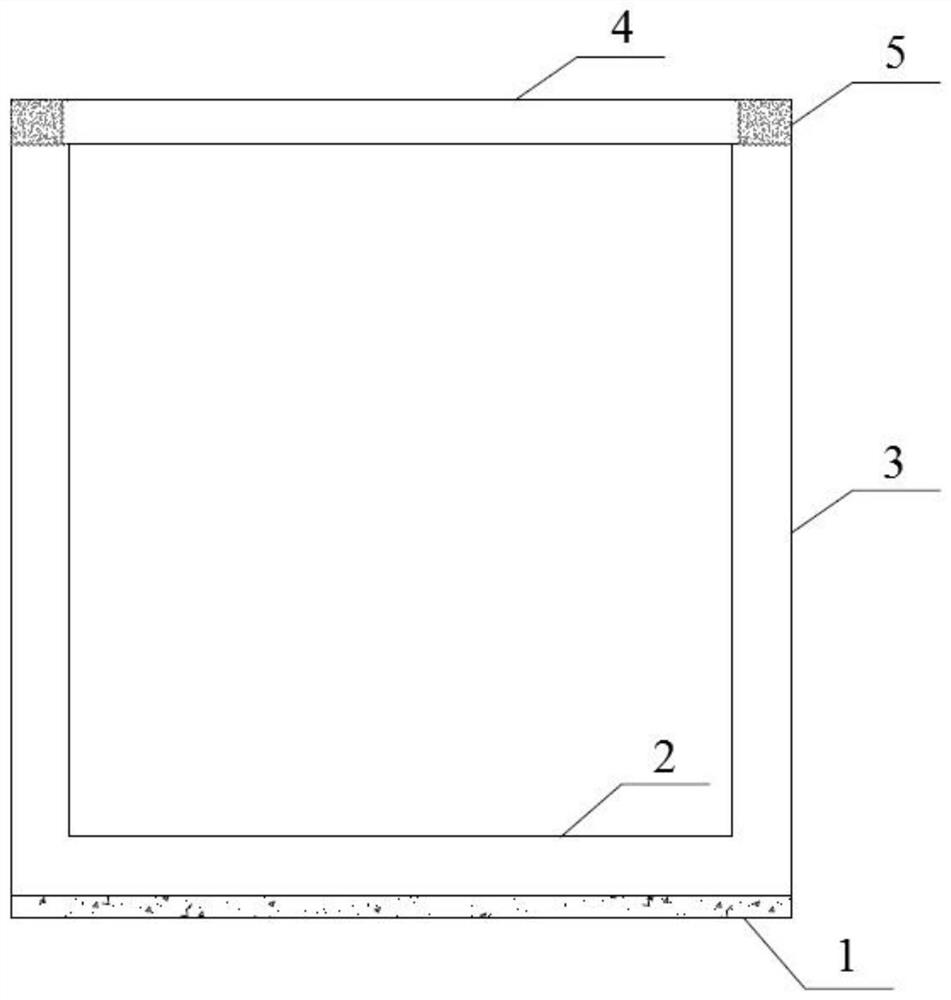

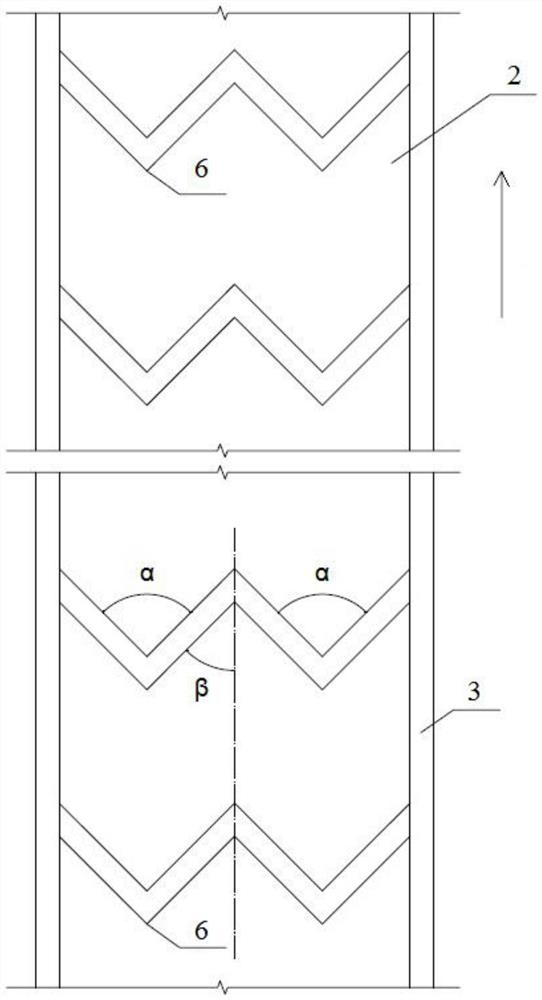

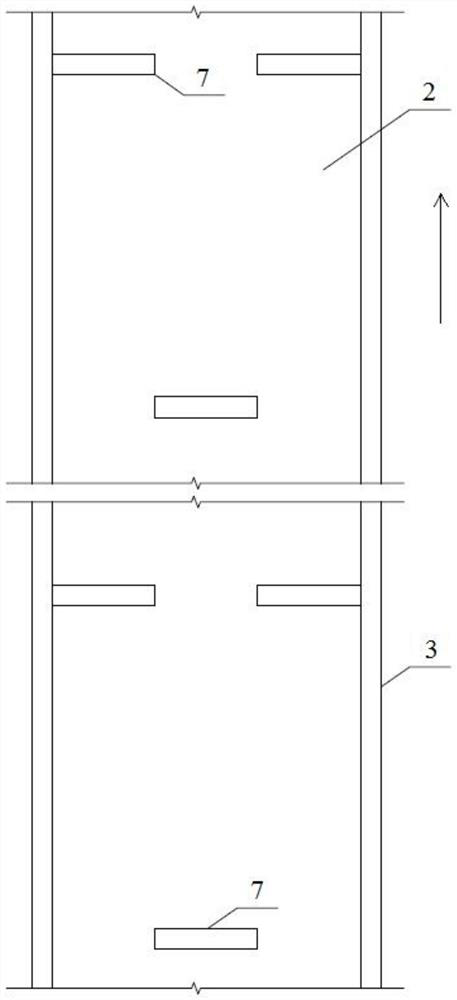

[0050] Such as Figure 1-Figure 4 As shown, a large-section flood drainage ditch for mountainous terrain includes a flood drainage ditch body, and the flood drainage ditch body includes a flood drainage ditch bottom plate 2 and flood drainage ditches arranged on both sides of the flood drainage ditch bottom plate 2 The side wall 3, the bottom plate 2 of the flood drainage ditch is provided with a falling water energy dissipation structure, the bottom plate 2 of the flood drainage ditch is provided with a concrete cushion 1, and the side wall 3 of the flood drainage ditch is also provided with a plurality of ditches Top beams 4, all of the trench top beams 4 are arranged at intervals along the length direction of the flood discharge ditch body, and a concrete post-casting belt 5 is also provided between the flood discharge ditch side walls 3 and the trench top beams 4 .

[0051] Wherein, the bottom plate 2 of the flood discharge ditch is 40 cm thick, and the side wall 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com