Construction method for environment-friendly light concrete cushion

A light-weight concrete and construction method technology, applied in infrastructure engineering, construction, etc., can solve problems such as environmental pollution, and achieve the effects of no radioactive pollution, reduced investment, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0030] The construction method of the environment-friendly light concrete cushion of the present invention is suitable for the filling layer of the ground and roof slopes of civil buildings, outdoor water distribution, open ditches, sidewalks and other ancillary projects.

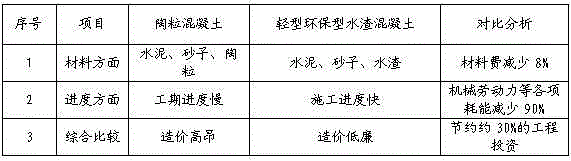

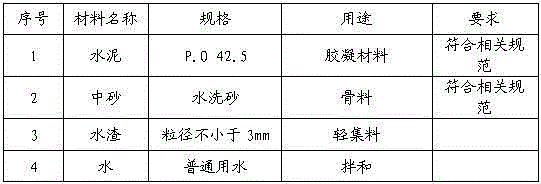

[0031] The raw materials used in the examples of the present invention are shown in Table 1 below.

[0032] Table 1 Construction materials

[0033]

[0034] Note: Water slag industrial waste, without other impurities, the particle size should not be less than 3mm, and the bulk density is 490kg / m 3 .

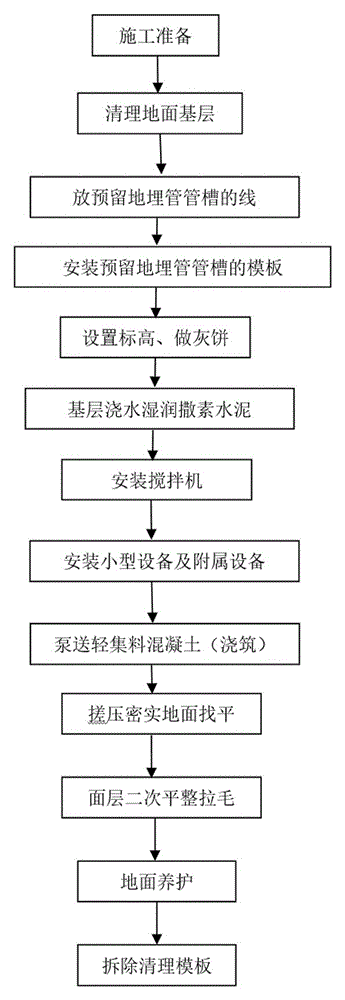

[0035] Such as figure 1 As shown, the flow chart of the construction method of the environmental protection lightweight concrete cushion of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com