Self-maintenance concrete

A concrete and self-curing technology, applied in the field of concrete, can solve the problems of inconvenience, the film reduces the surface friction coefficient, and there is no maintenance, etc., and achieves the effect of extensive use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the self-curing concrete proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Details are as follows.

[0035] In order to make the maintenance of concrete more convenient and effective, the present invention uses high-efficiency moisturizing powder (humectation powder) with moisturizing and water-absorbing properties to add to the concrete during mixing, so that the concrete can achieve "self-curing" after pouring. Curing)" purpose and efficacy. The so-called "self-curing concrete" means that it does not need to provide additional concrete moisture manually, and even can achieve the purpose of self-curing without any external maintenance after pouring.

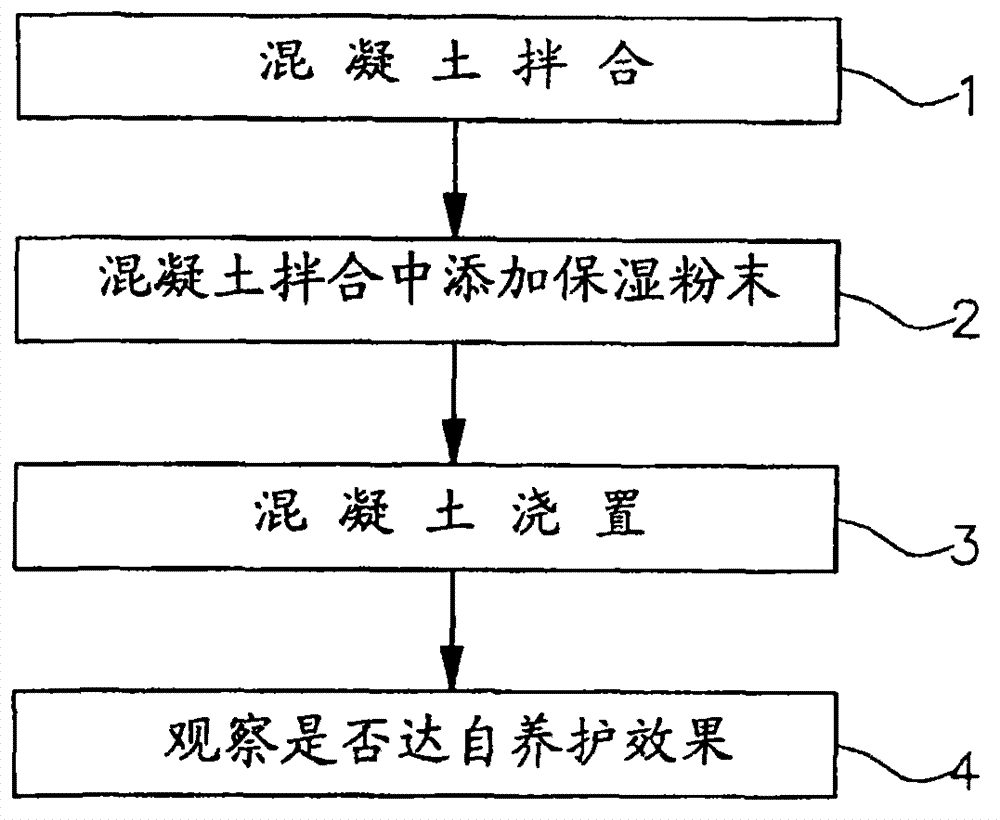

[0036] seefigure 1 Shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com