A lightweight assembled anti-collision fence assembly and an installation method thereof

An anti-collision guardrail and assembled technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as high cost, substandard concrete quality, cumbersome construction procedures, etc., achieve high durability and stability, and easily guarantee construction quality , Fast and convenient construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

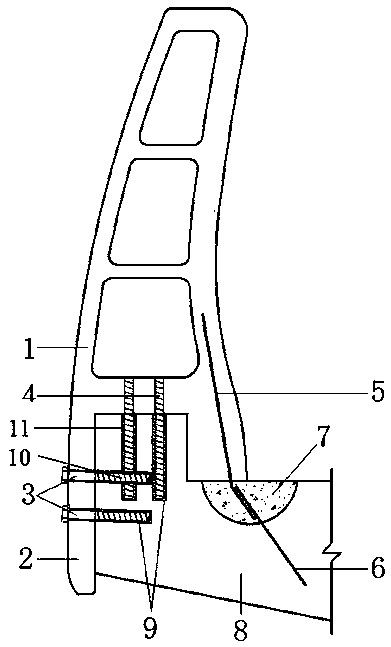

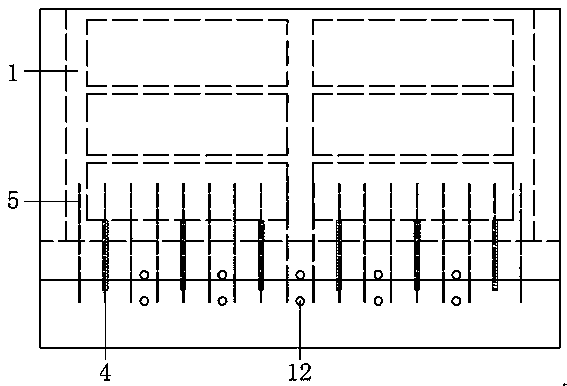

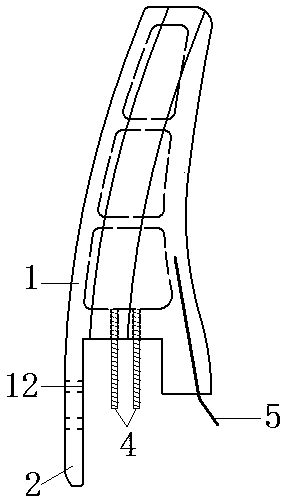

[0034] refer to Figure 1~5 : A light assembled anti-collision guardrail assembly, including prefabricated guardrail 1, vertical bolt 4, horizontal bolt 3, steel bars and bridge flange plate 8, bridge flange plate 8 is provided with vertical bolt hole 11 and horizontal bolt hole 10 , the vertical bolts 4 are installed at the bottom of the prefabricated guardrail 1 and inserted into the vertical bolt holes 11, the horizontal bolts 3 are inserted into the horizontal bolt holes 10 through the prefabricated guardrail 1, and are interlaced with the vertical bolts 11, and the reinforcing bars include the prefabricated guardrail steel bars 5 and bridge flange steel bar 6, after docking, weld the two together, then pour ultra-high performance concrete to form anchor belt 7, prefabricated guardrail 1 is prefabricated in sections, the bottom is made into an inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com