Capacitive flexible tensile sensor based on S-shaped micro-channel liquid metal composite dielectric layer

A liquid metal and composite medium technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of restricting the application and popularization of liquid metal, the high requirements of Cu plate mold processing technology, etc., achieve excellent deformation characteristics, improve anti-interference, The effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

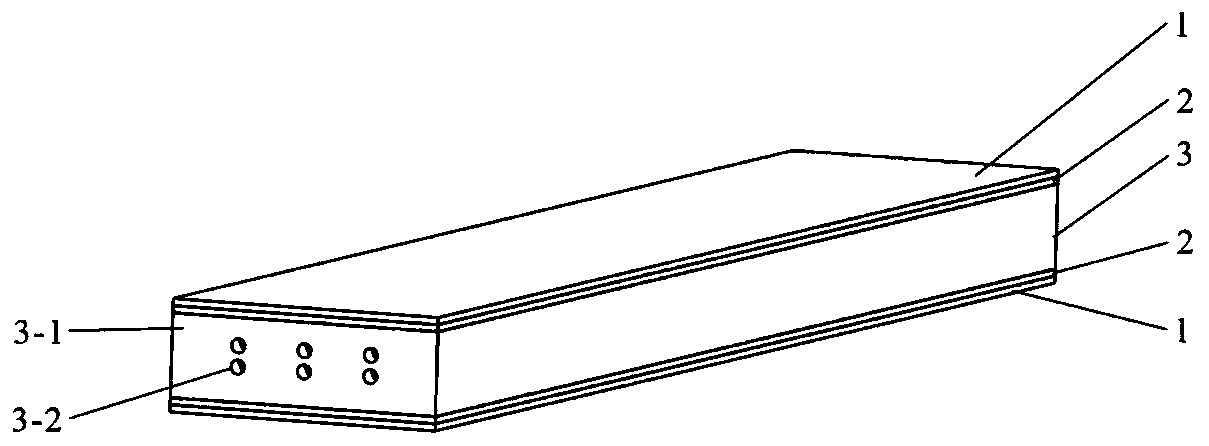

[0032] like figure 1 and figure 2 As shown, in this embodiment, the capacitive flexible tensile sensor based on the S-type micro-channel liquid metal composite medium layer is mainly composed of a flexible packaging layer 1, a flexible electrode 2 and an S-type micro-channel liquid metal composite medium layer 3;

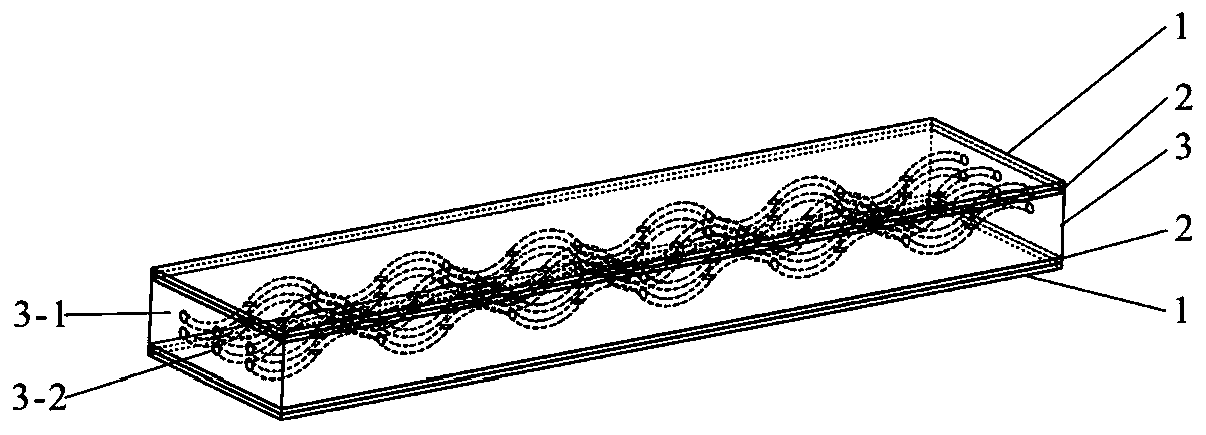

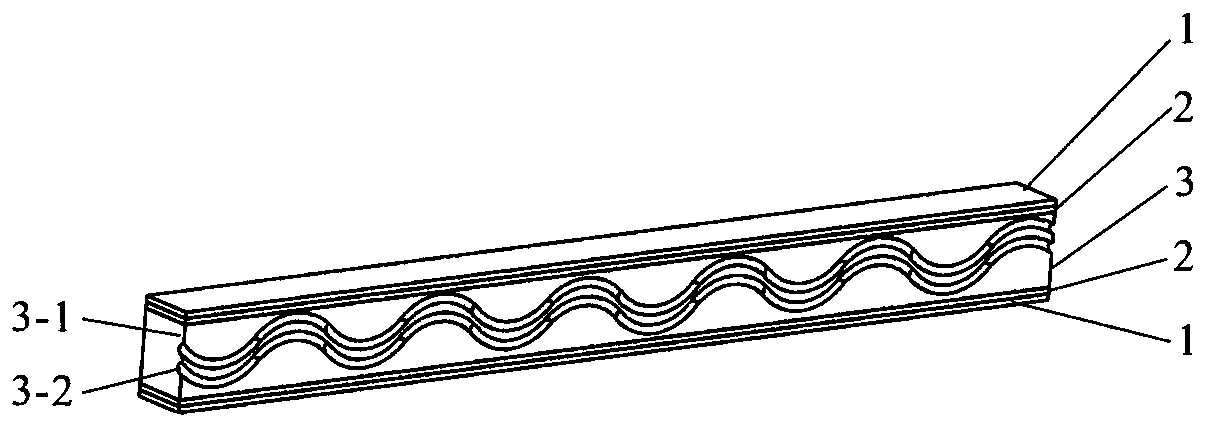

[0033] Among them, the S-shaped micro-channel liquid metal composite medium layer 3 is provided with an S-shaped micro-channel cavity 3-2 in a rectangular flexible substrate 3-1 and filled with a liquid state in the S-shaped micro-channel cavity 3-2. metal, and sealed at the opening; the S-shaped micro-channel cavities 3-2 are distributed along the radial direction of the rectangular flexible substrate, and the shape is continuous S-shaped (such as image 3 shown);

[0034] A flexible electrode 2 and a flexible encapsulation layer 3 are sequentially arranged on the upper and lower surfaces of the S-shaped microchannel liquid metal composite dielectric layer 3 to ...

Embodiment 2

[0038] like Figure 4 to Figure 6 As shown, the S-shaped microchannel cavity has a bionic structure similar to plant rhizomes, and its structural parameters include microchannel radius, microchannel bending amplitude, microchannel bending frequency, number of single-layer microchannels, microchannel The number of layers and the cross-sectional shape of the channel will affect the spatial distribution of the S-shaped microchannel cavity in the rectangular flexible matrix.

[0039] The microchannel radius, microchannel bending amplitude, microchannel bending frequency and channel cross-sectional shape of the S-shaped microchannel cavity, wherein the microchannel bending amplitude is the ratio of the transverse length to the radial length of a single S-shaped structure, The bending frequency of the microchannel is the number of complete S-shaped structures in the tensile strain sensor under the condition that the bending amplitude of the microchannel is determined. Usually, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com