Forming method for amorphous alloy component

A technology for amorphous alloys and components, which is applied in metal processing equipment, equipment for feeding molten metal into casting molds, and casting molten material containers, etc. It can solve the strict requirements of temperature control and deformation time, and can not meet the requirements of product use. , The product is prone to crystallization and other problems, and achieves the effect of low solidification shrinkage coefficient, high production efficiency and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The forming process of this embodiment is specifically as follows:

[0024] 1. Master alloy composition: Ti32.8Zr30.2Ni5.3Cu9Be22.7 (atomic percentage).

[0025] 2. Master alloy smelting: the alloy is prepared according to the design composition, then placed in the crucible, and vacuumed to 5×10- 1 ~5×10 -3 Pa (can also be filled with inert protective gas), use induction melting or arc melting technology to obtain master alloy with uniform composition, and cast into regular master alloy ingot (such as rod, plate or sheet, etc.).

[0026] 3. Master alloy cutting: According to the quality of amorphous alloy components, cutting equipment is used to cut the cast alloy ingot into the required size.

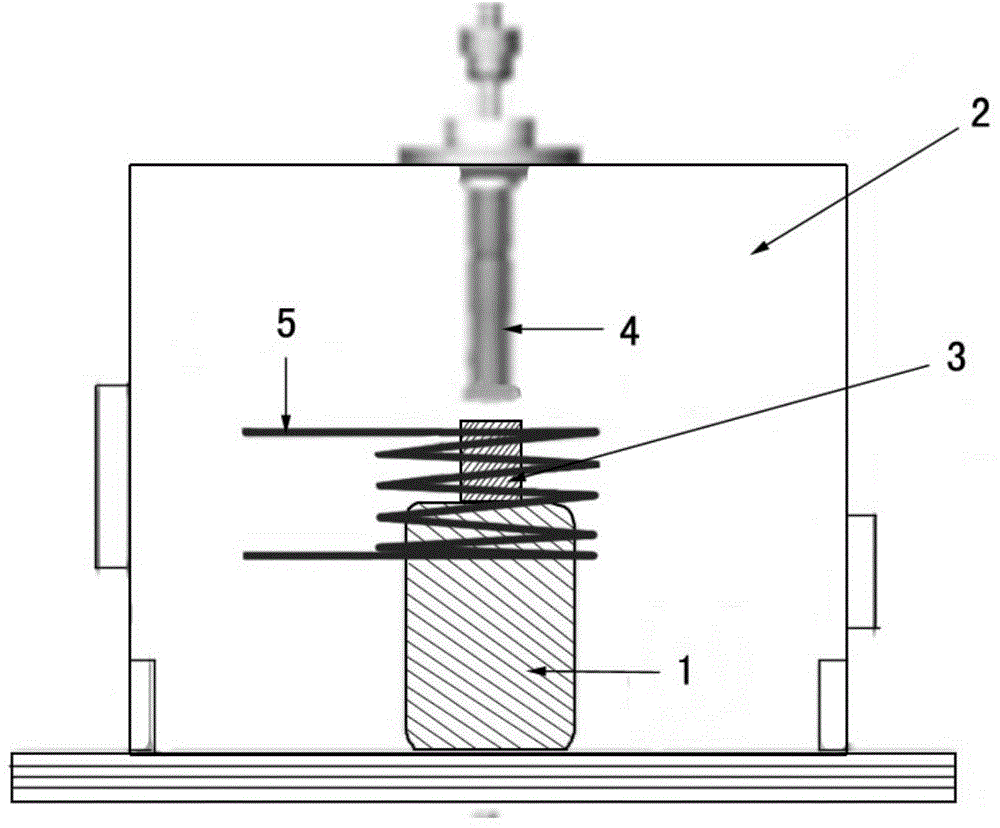

[0027] 4. Forming and processing of amorphous alloy components: place the cut master alloy on the melting platform and vacuumize to 1×10 -1 ~1×10 -3 Pa (can also be filled with inert protective gas), use induction heating (arc heating or laser heating and other heating metho...

Embodiment 2

[0029] The difference from Example 1 is that the selected master alloy composition is Zr54.73Cu29.75Ni4.97Al9.95Ag0.1Y0.5 (atomic percentage), and the components of pure amorphous structure are obtained such as image 3 shown.

[0030] Depend on Figure 2-3 It can be seen that the surface finish of the amorphous alloy component prepared by the present invention is good and the dimensional accuracy is high, and by SEM observation and analysis, the component interior is dense and free of defects such as shrinkage cavities ( Figure 4 ).

[0031] The alloy components of the present invention can be all amorphous alloy systems, such as Ti-based amorphous alloys, Zr-based amorphous alloys, Fe-based amorphous alloys, Ni-based amorphous alloys, Mg-based amorphous alloys, Pd-based amorphous alloys, Ag-based amorphous alloy, Hf-based amorphous alloy, Pt-based amorphous alloy and other amorphous alloy components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com