Fullerene-based wire cut electrical discharge machining water-soluble composite working solution and preparation method thereof

A water-soluble composite, EDM wire technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of short service life of composite working fluid, high surface roughness of processed workpiece, easy rust of workpiece, etc., to save workpiece processing. Time, improve the processing quality, the effect of excellent anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

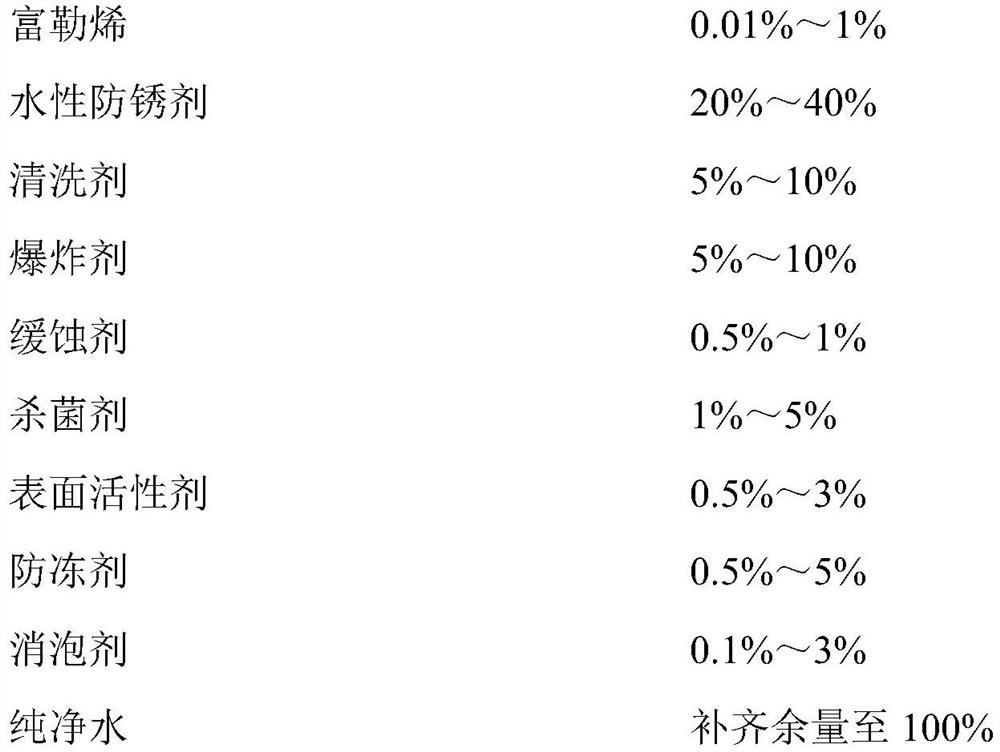

Method used

Image

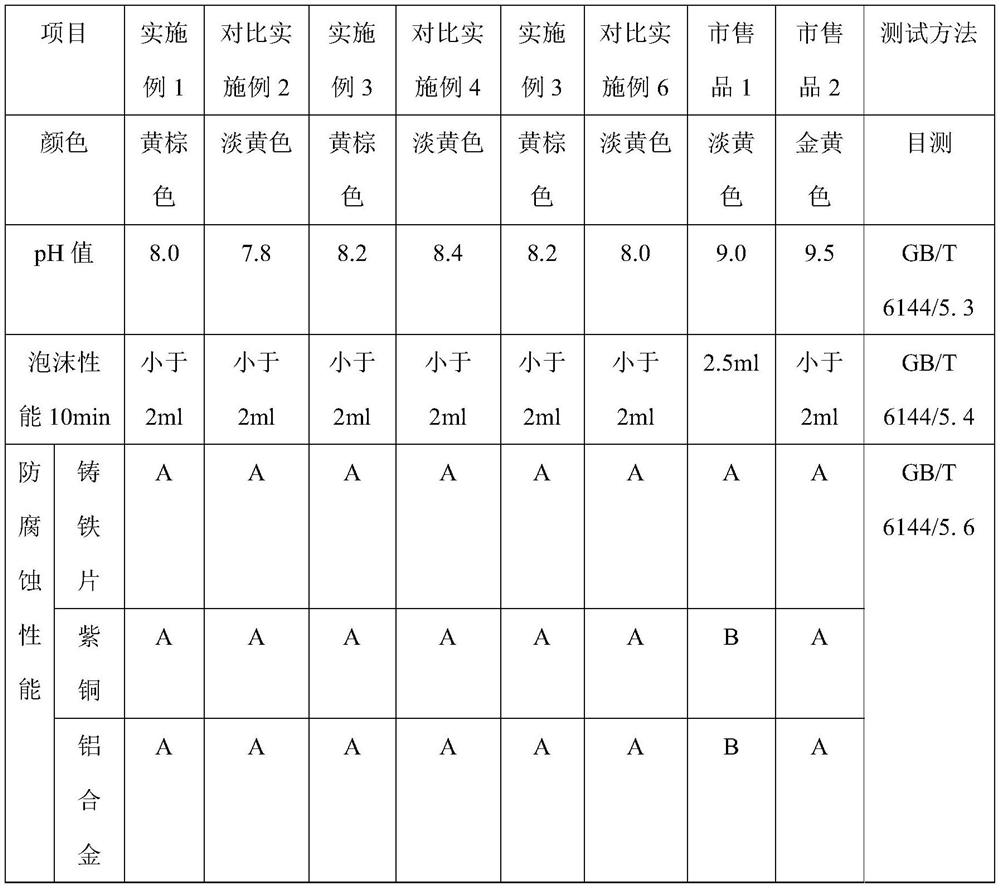

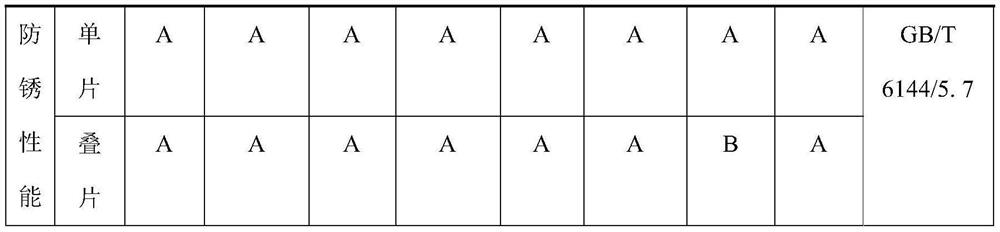

Examples

Embodiment 1

[0029] The fullerene-based wire electric discharge water-soluble composite working fluid of this embodiment is prepared according to the mass percentage of raw materials, including the following components: fullerene (fullerene C 60 Alcohols) 0.5%, water-based rust inhibitor (monoethanolamine and triethanolamine mixed in a weight ratio of 1:1) 30%, cleaning agent (glycerol and ethylene glycol mixed in a weight ratio of 1:1) 8%, explosive agent ( Polyethylene glycol) 5%, corrosion inhibitor (benzotriazole) 0.5%, fungicide (anilide) 2%, surfactant (amide) 2%, antifreeze agent (formamide) 1%, defoamer agent (polydimethylsiloxane) 0.5%, purified water to make up the balance to 100%. The preparation process is as follows: (a) dissolving fullerene in a certain amount of pure water, and then adding water-based antirust agent, cleaning agent, blasting agent and corrosion inhibitor in sequence after completely dissolving, and reacting at 60°C for 1.5 hours to obtain a mixed solution; ...

Embodiment 3

[0035] The fullerene-based wire electric discharge water-soluble composite working fluid of this embodiment is prepared according to the mass percentage of raw materials, including the following components: fullerene (fullerene C 70Alcohols) 0.7%, water-based antirust agent (diethanolamine and butanolamine mixed in a weight ratio of 2:1) 25%, cleaning agent (diethylene glycol, ethylene glycol and butanol mixed in a weight ratio of 1:2:1 ) 6%, blasting agent (sucrose and polyethylene glycol mixed at a weight ratio of 1:2) 8%, corrosion inhibitor (benzotriazole and tolyltriazole mixed at a weight ratio of 2:1) 0.7 %, bactericide (acylanilide and ammonium dihydrogen phosphate mixed at a weight ratio of 1:1) 3%, surfactant (stearic acid and amide mixed at a weight ratio of 1:1) 1%, antifreeze (formamide) 3% %, defoamer (polypropylene oxide) 2%, purified water to make up the balance to 100%. The preparation process is: (a) dissolving fullerene in a certain amount of pure water, an...

Embodiment 5

[0041] The fullerene-based wire electric discharge water-soluble composite working fluid of this embodiment is prepared according to the mass percentage of raw materials, including the following components: fullerene (fullerene C 60 Alcohols and fullerenes C 70 Alcohols are mixed in a weight ratio of 1:1) 0.5%, water-based rust inhibitors (diethanolamine and butanolamine are mixed in a weight ratio of 1:1) 30%, cleaning agents (diethylene glycol, ethylene glycol and butanol are mixed by weight) ratio 1:2:2) 6%, blasting agent (sucrose and polyethylene glycol mixed in weight ratio 1:1) 6%, corrosion inhibitor (benzotriazole and tolyltriazole by weight 1:2 mixing ratio) 0.8%, fungicide (acyl anilide and ammonium dihydrogen phosphate mixed at a weight ratio of 1:1) 2%, surfactant (stearic acid and amide mixed at a weight ratio of 1:1) 4%, Antifreeze (formamide) 1%, defoamer (polypropylene oxide) 0.5%, purified water to make up the balance to 100%. The preparation process is: (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com