Patents

Literature

31results about How to "Good slagging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

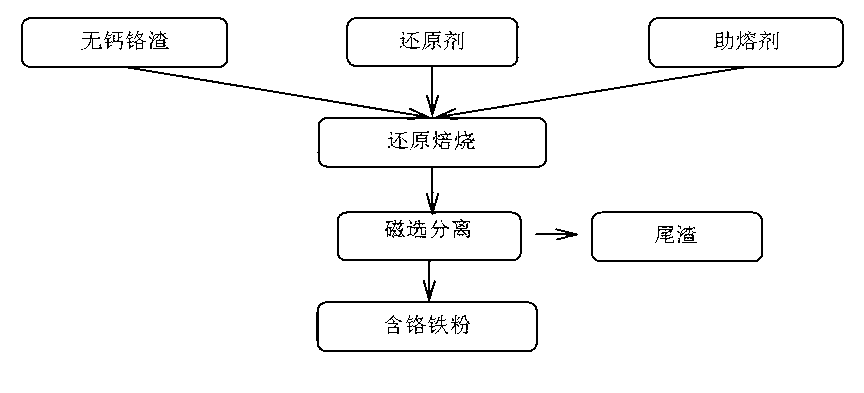

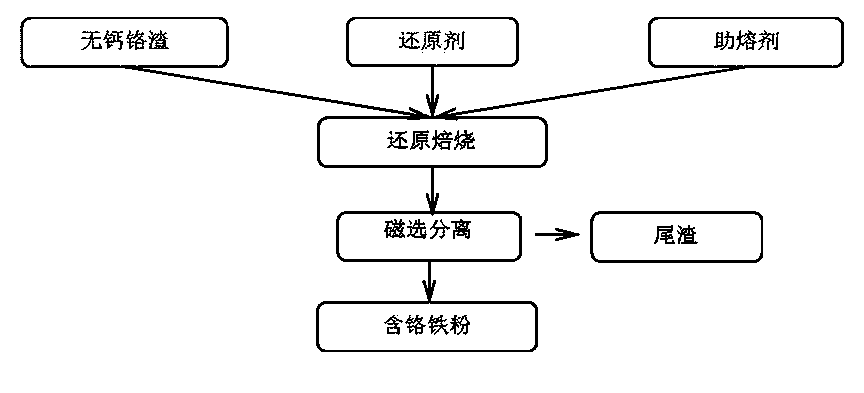

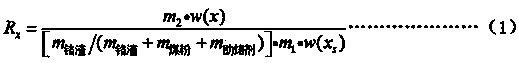

Method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag

ActiveCN102796879AHigh degree of resource utilizationEfficient separationProcess efficiency improvementIron powderMixed materials

The invention discloses a method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag, which belongs to the technical field of comprehensive utilization of chromium slag. The method comprises the following steps of: firstly, material preparation, wherein the calcium-free chromium slag is mixed with a reducing agent and fluxing agents comprising alumina, and the four-element alkalinity m(MgO+CaO) / m(SiO2+Al2O3) of the mixed material is equal to 0.9 to 1.3; secondly, agglomeration, wherein the mixed material is pressed or pelletized to obtain agglomerates; thirdly, reduction roasting, wherein the agglomerates are roasted in reducing atmosphere at a reduction temperature of 1,250 to 1,350 DEG C for 30 to 240 minutes; fourthly, crushing and fine grinding, wherein the roasted agglomerates are crushed and ground to be fine; and fifthly, magnetic separation, wherein the finely ground powder is subjected to magnetic separation at magnetic induction intensity of 100 to 200 mT, thereby separating the chromium-containing iron powder. According to the method, the calcium-free chromium slag is completely detoxified and fully recycled, the grade sum of calcium and iron in the prepared chromium-containing iron powder is over 80 percent, the chromium recovery rate and the iron recovery rate are respectively over 78 percent, and the method is low in energy consumption and free from secondary pollution.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

Preparation method of scouring agent for aluminum and aluminum alloy

The invention relates to a preparation method of a scouring agent for aluminum and an aluminum alloy, which comprises the following steps: firstly, selecting ingredients according to the following percentages by weight: 30-85% of NaCl, 5-40% of Na2SiF6, 5-40% of Na2SO4, 2-20% of CaF2 and 0.5-10% of C6Cl6; uniformly mixing and fully stirring the selected ingredients; placing the mixture into a crucible, carrying out overheat melting to eliminate crystal water, and preserving the temperature for 30-60 minutes; and finally, processing after cooling to obtain the scouring agent. The method has the advantages of simple process and low cost. The prepared scouring agent does not contain sylvite, so that sylvite can not be introduced into the scouring and purifying treatment procedures, and therefore, an aluminum electrolysis cell can not be seriously corroded as a result of the introduction of sylvite when aluminum ash is directly recycled in the cell.

Owner:包头市一禾稀土铝业科技材料有限公司

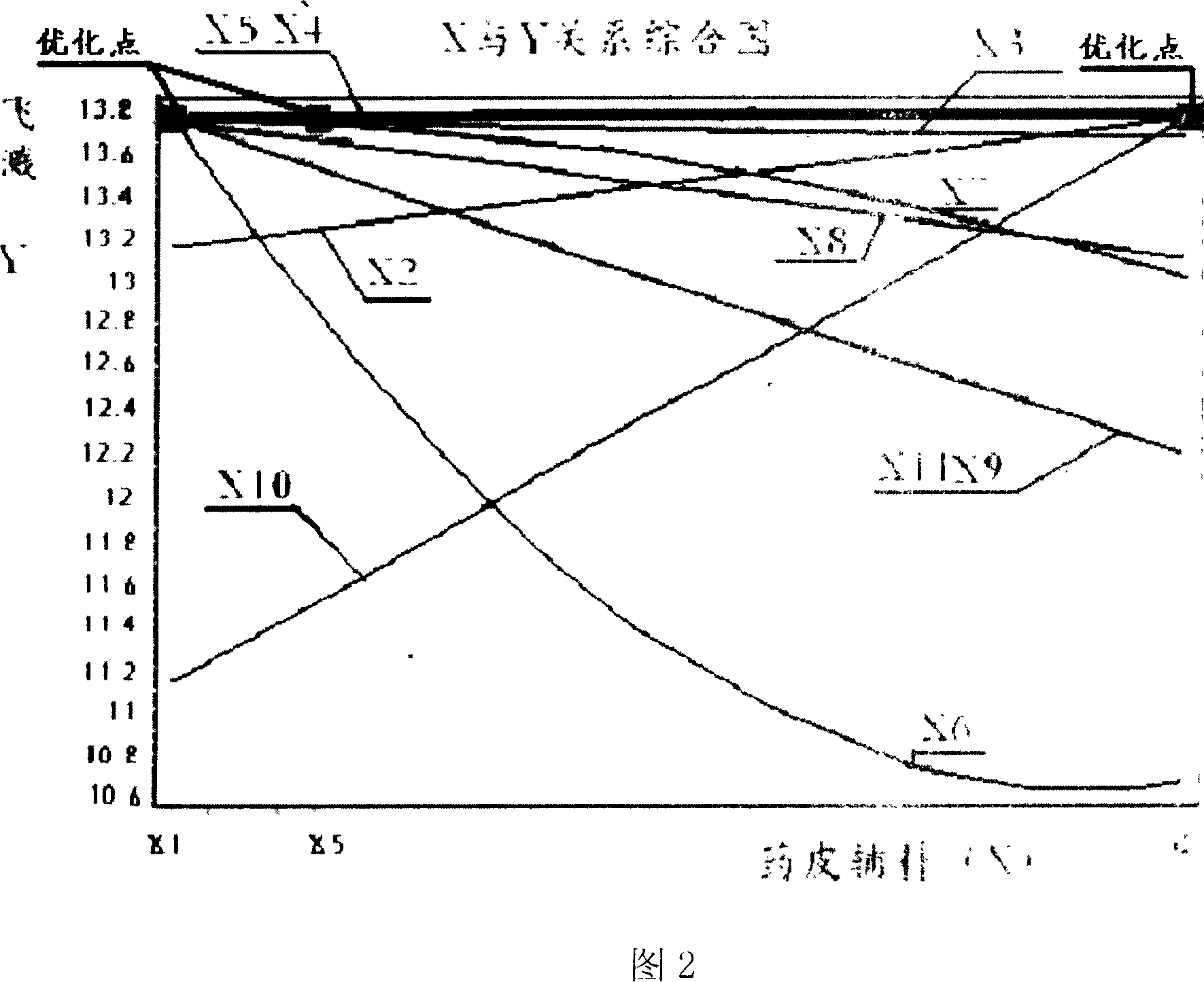

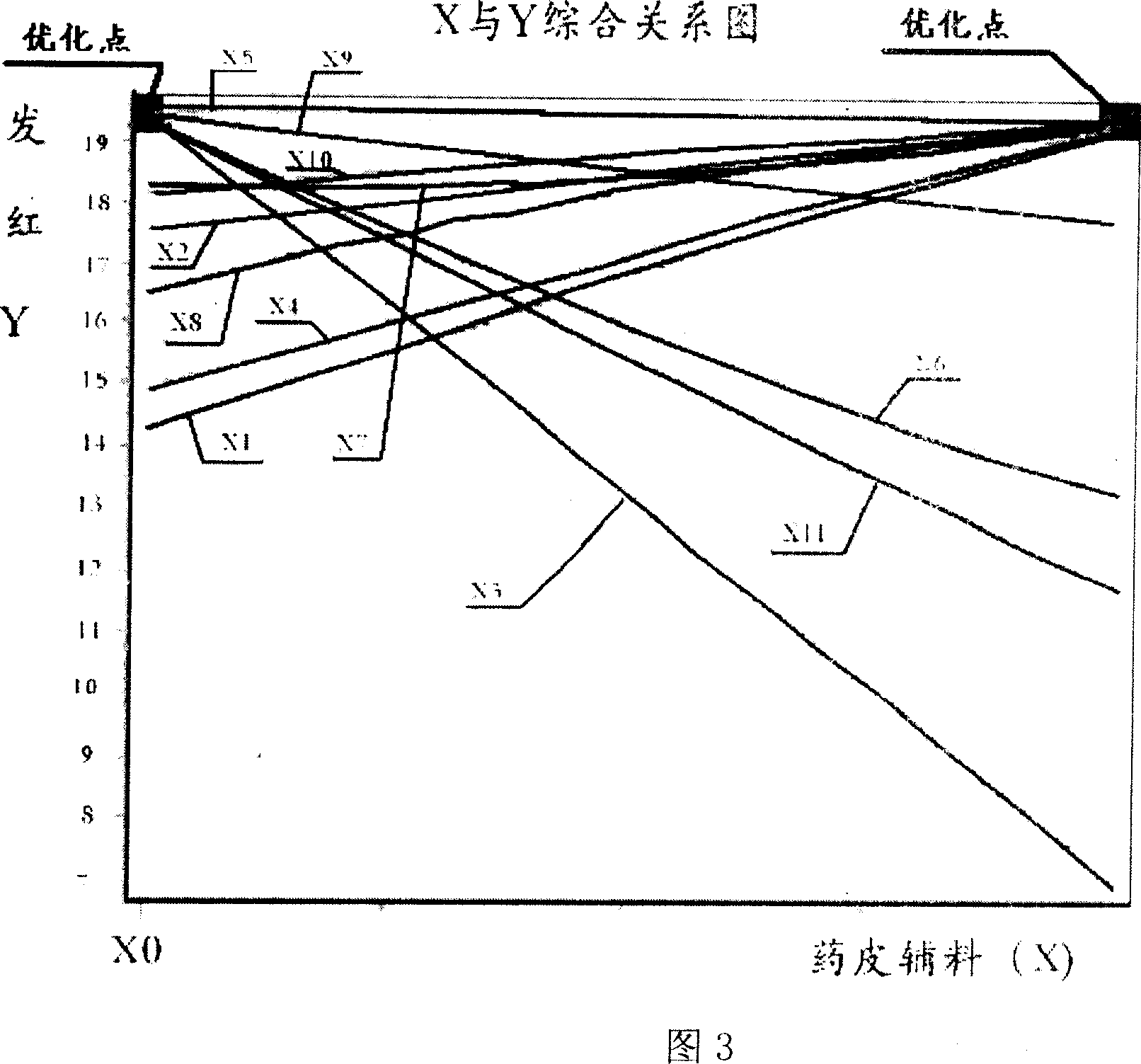

Stainless steel welding rod of new dregs series

InactiveCN1958213AReduce slag viscosityImprove conductivityWelding/cutting media/materialsSoldering mediaArc stabilitySlag

A welding stainless steel electrode with improved slag detachability and welding quality is composed of a core and a coated flux layer prepared proportionally from rutile, feldspar, marble, fluorite, wollastonite, megnesite, titaniunm oxide powder, hematite, aluminum fluoride, mice, barium carbonate, Cr, Ni, sodium carbonate, electrolytic manganese and ferrotitanium.

Owner:HARBIN UNIV OF SCI & TECH

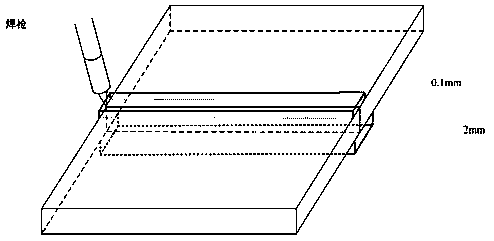

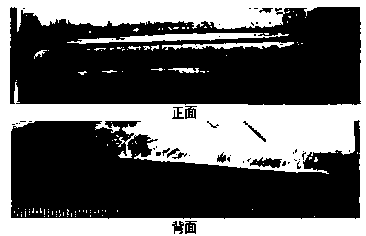

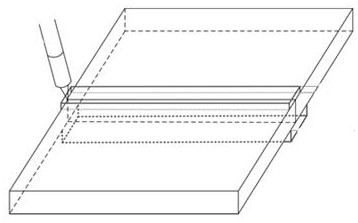

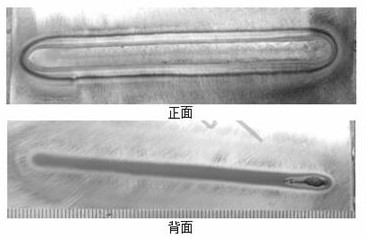

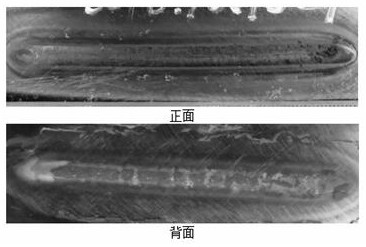

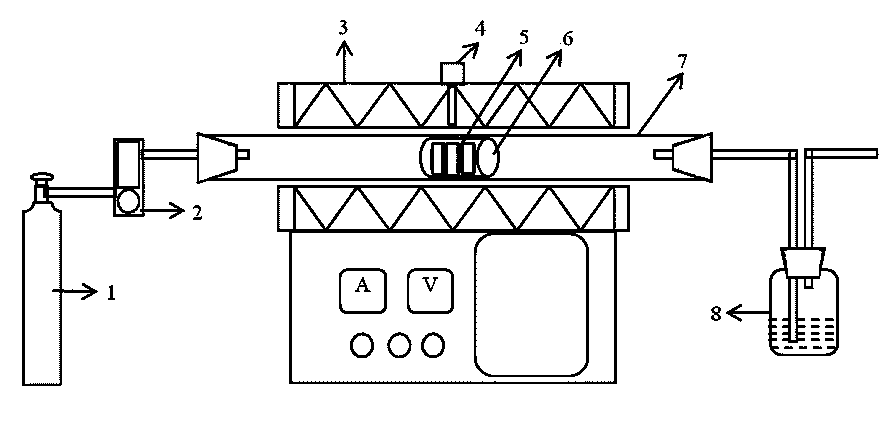

TIG welding method for improving the welding penetration depth and preventing the back oxidation

ActiveCN109604868AIncrease coverageHigh affinityArc welding apparatusWelding/cutting media/materialsMass ratioSlag

The invention discloses a TIG welding method for improving the welding penetration depth and preventing the back oxidation. The TIG welding method for improving the welding penetration depth and preventing the back oxidation comprises the following steps that firstly, the powder is mixed with a binder according to the mass ratio of 1:4-6, the protective agent is formed, then the protective agent is diluted with acetone at a ratio of 1:5-3:1, the powder comprises the following components of, in percentage by mass, 20%-32% of SiO2, 4%-10% of CaF2, 25-35% of TiO2, 5%-12% of MnO2, 15%-30% of Mn and 16%-25% of Si; secondly, then the protective agent is brushed on the front surface and the back surface of the welding opening, the coating thickness of the front surface is 0.1mm, the thickness ofthe back surface is 2 mm, standing is carried out for 5-10 minutes in air, and then welding is carried out. According to the TIG welding method for improving the welding penetration depth and preventing the back oxidation, the penetration depth of the TIG welding can be greatly improved, the back oxidation of the weld joint can be prevented, forming defects such as weld joint slag inclusion, gas holes, welding penetration and the like are overcome, and one-time welding forming of the stainless steel in the thickness of 5-10 mm is achieved; according to the TIG welding method, a complex multi-layer welder is omitted, the production period is shortened, the energy consumption is reduced, the cost is saved, and the forming quality of the TIG one-time welding is greatly improved.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for preparing refining agent from egg shell carrier

The invention discloses a method for preparing a refining agent from an egg shell carrier, and belongs to the technical field of preparation of refining agents. The method comprises the following steps that an egg shell is used as a carrier, the egg shell is carbonized after the surface of the egg shell is processed, the carbonized egg shell is put in a solution containing potassium chloride, magnesium chloride, sodium sulfate, zinc chloride and sodium nitrate to be soaked and adsorbed, the adsorbed egg shell and the solution are dried, and the dried material, calcium fluoride, pyrophyllite, diatomaceous earth, pulverized fuel ash and rare earth are mixed, and the mixture is ball-milled to obtain the refining agent. The stability of a refining agent additive obtained after the egg shell is adsorbed can be improved. The inclusion adsorbing capability of the egg shell is high, the cost is low, the prepared refining agent is high in chemical stability, the slagging performance is high, the gas and inclusion removing capability is high, and the method has a wide market prospect.

Owner:陈建峰

Novel environment-friendly synthetic slag forming material

ActiveCN105734197ASolve the problem of weak slag removal abilityGood slagging performanceManufacturing convertersProcess efficiency improvementEnvironmental resistanceSlag

The invention provides a novel environment-friendly synthetic slag forming material which comprises the following raw material components in parts by weight: 11-14 parts of CaO, 5-25 parts of aluminum ash powder, 70-73 parts of SiO2, 1-2 parts of MnO, 8-10 parts of FeO and 2-5 parts of Y2O3. The novel environmental-friendly synthetic slag forming material is environment-friendly, superior in slag forming performance, and wide in raw material sources, belongs to a resource recycling material, is low in pollution on molten steel during the steel-making using process, and small in generated slag quantity, can remarkably improve the comprehensive performance of a steel-making slag system, and improves the quality of molten steel. The novel environment-friendly synthetic slag forming material, namely a slag former, belongs to comprehensive utilization of industrial wastes, and is reliable in process, low in cost, and profitable.

Owner:山东济钢泰航合金有限公司

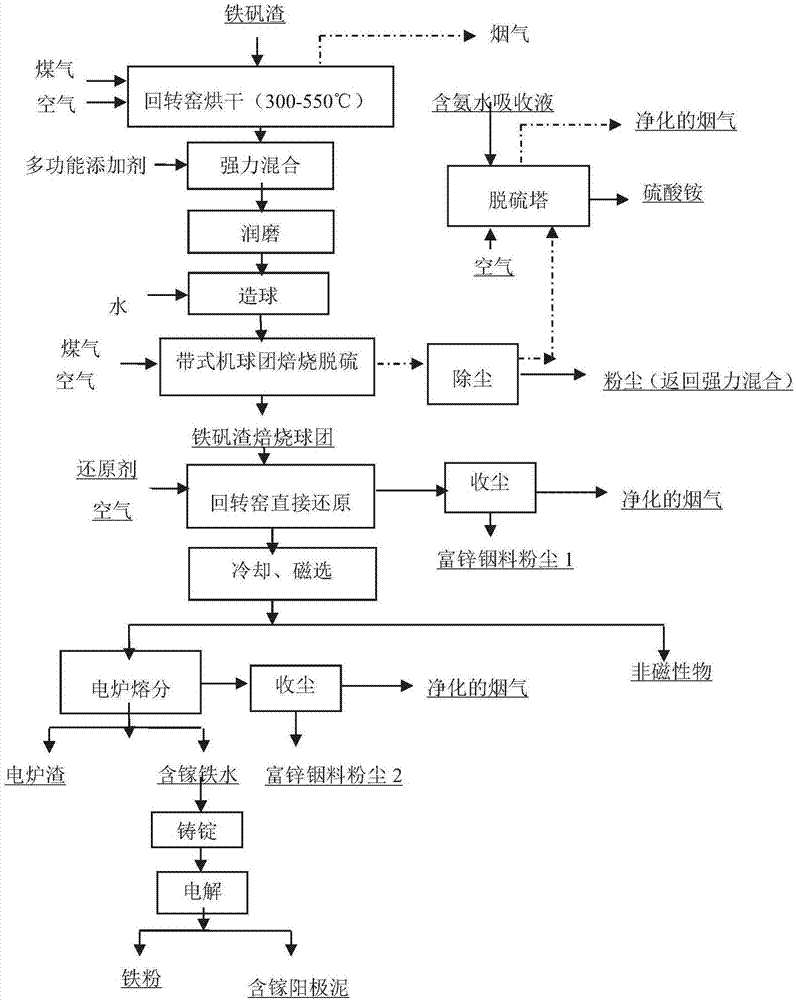

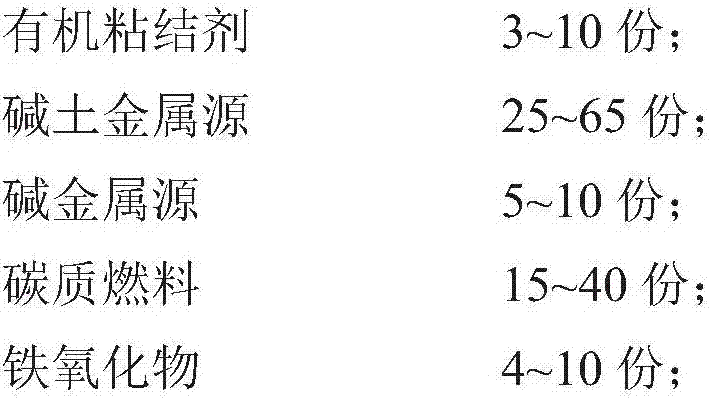

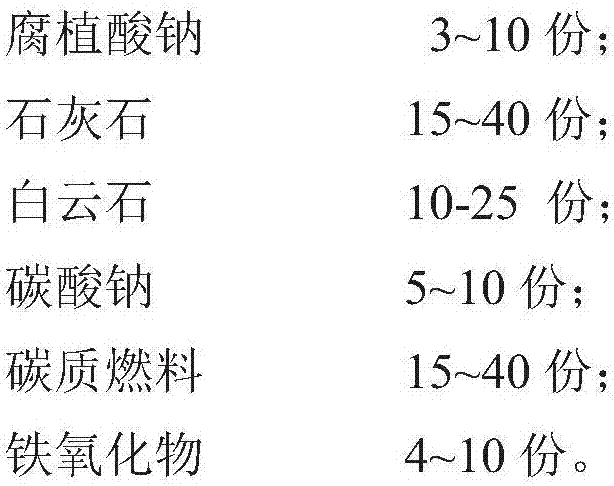

Method for extracting valuable elements from jarosite slag

ActiveCN107267745AReduce expansionImprove reducibilityProcess efficiency improvementIndiumElectrolysis

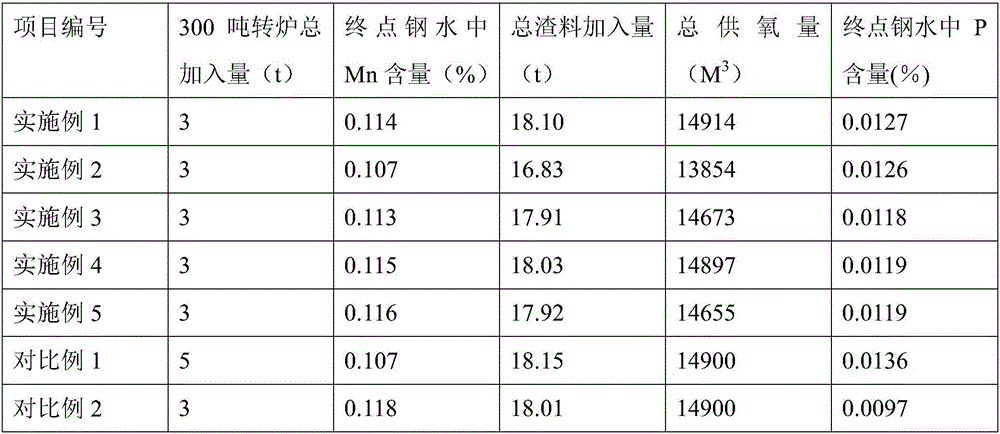

The invention discloses a method for extracting valuable elements from jarosite slag. The method specially includes the steps of pelletization, oxidation roasting desulfurization, direct reduction, smelting separation, ingot casting, electrolysis and the like. A special additive agent disclosed by the invention is adopted in the pelletization process, and the additive agent comprises an organic binder, an alkaline earth metal source, an alkaline metal source, carbonaceous fuel and iron oxide. By the adoption of the method, by means of extensive research and test certification, the additive agent is used so that pelletization can be enhanced, the roasting desulfurization and consolidation effect of pellets is improved, the strength of the roasted pellets is enhanced, the reducibility of the roasted pellets is improved, the reduction swelling rate of the pellets is lowered, the mobility of the slag is improved, desulfurization capacity of the slag is also improved, and the subsequent process is matched to achieve efficient separation and extraction of the various valuable elements like iron, gallium, zinc, indium and sulfur.

Owner:CENT SOUTH UNIV +1

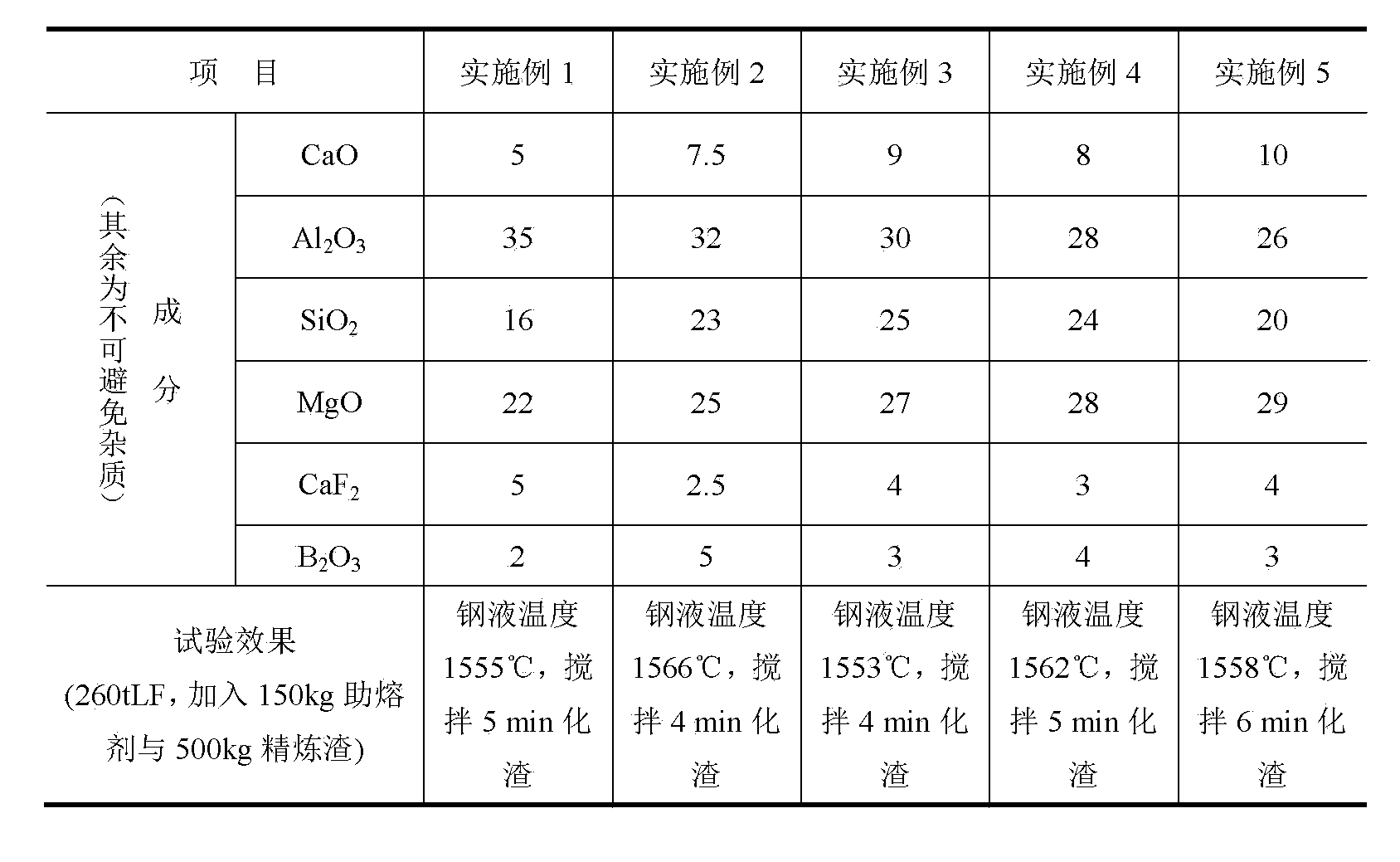

Molten steel refining fluxing agent and its making method

ActiveCN103509910ALow melting pointPromote meltingProcess efficiency improvementProduction rateChemical composition

The invention provides a molten steel refining fluxing agent and its making method. The fluxing agent comprises the following chemical components by weight: 5%-10% of CaO, 20%-30% of MgO, 2%-5% of CaF2, 25%-35% of Al2O3, 2%-5% of B2O3, 15%-25% of SiO2, and the balance less than 20% of inevitable impurities. The making method comprises: 1) conducting burdening: mixing 100-200 mesh industrial raw material powder containing CaO, Al2O3, SiO2, MgO, B2O3 and CaF2 uniformly according to the weight percentage of the fluxing agent; 2) performing ball making: adding 5%-10% of water glass, mixing them evenly, and pressing the mixture into a spherical material; 3) subjecting the spherical material to baking drying for 1-2h at 250-300DEG C, and then cooling the spherical material to room temperature for 4-6h; and 4) conducting screening to obtain the material with a particle size of 10-40mm and a weight content of greater than or equal to 95%, i.e. a finished product. The molten steel refining fluxing agent provided by the invention lowers the melting point of refining slag, shortens the slagging time, improves the refining production rate, and does not pollute the molten steel, and slightly erodes the furnace lining. Compared with the use of fluorite, the production cost is low, and the environmental pollution is small.

Owner:ANGANG STEEL CO LTD

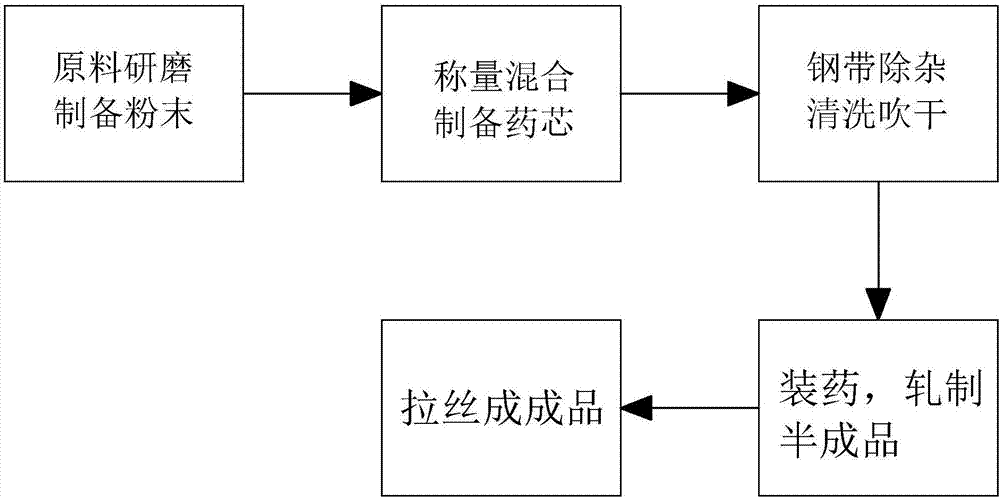

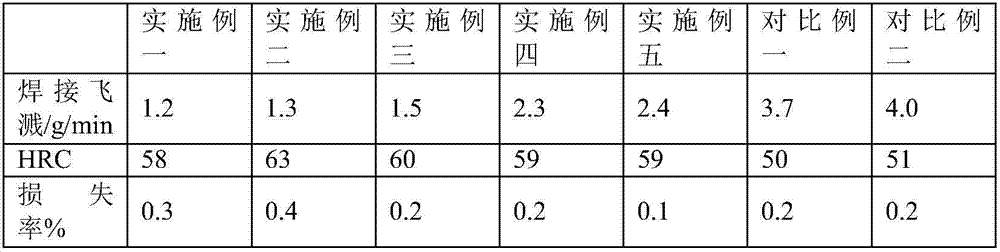

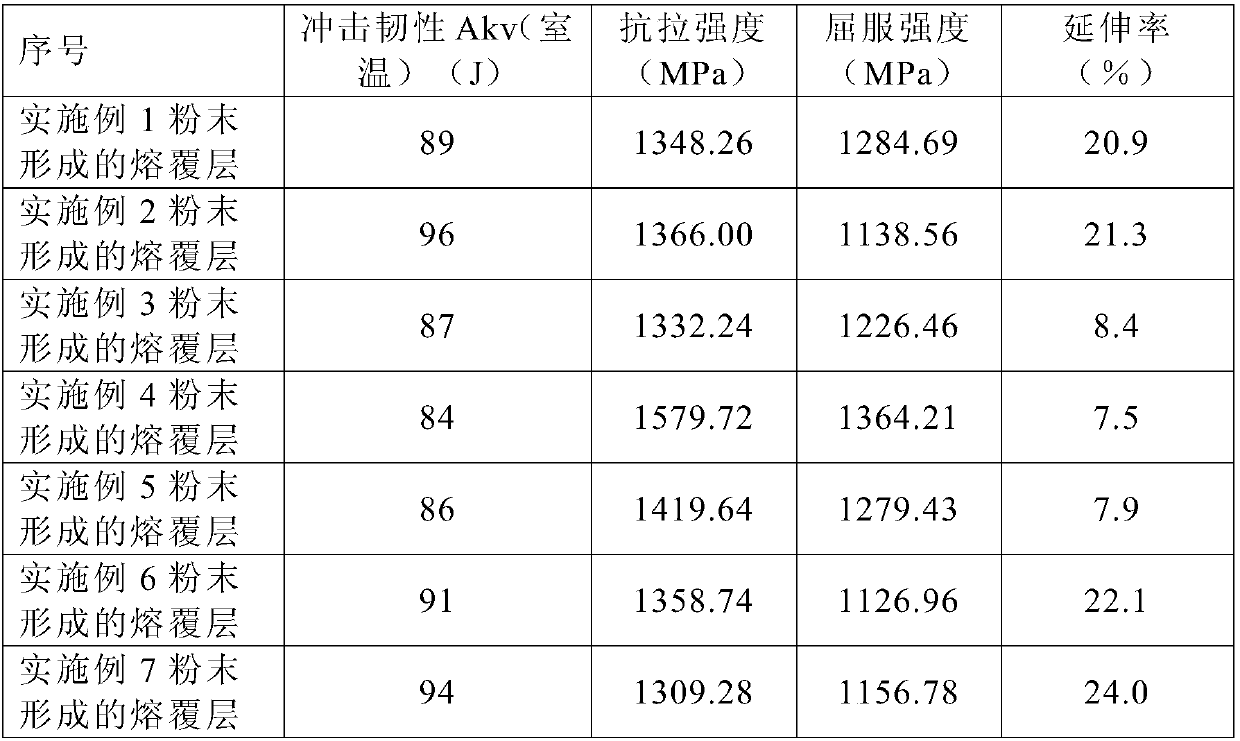

Flux-cored wire and preparation method thereof

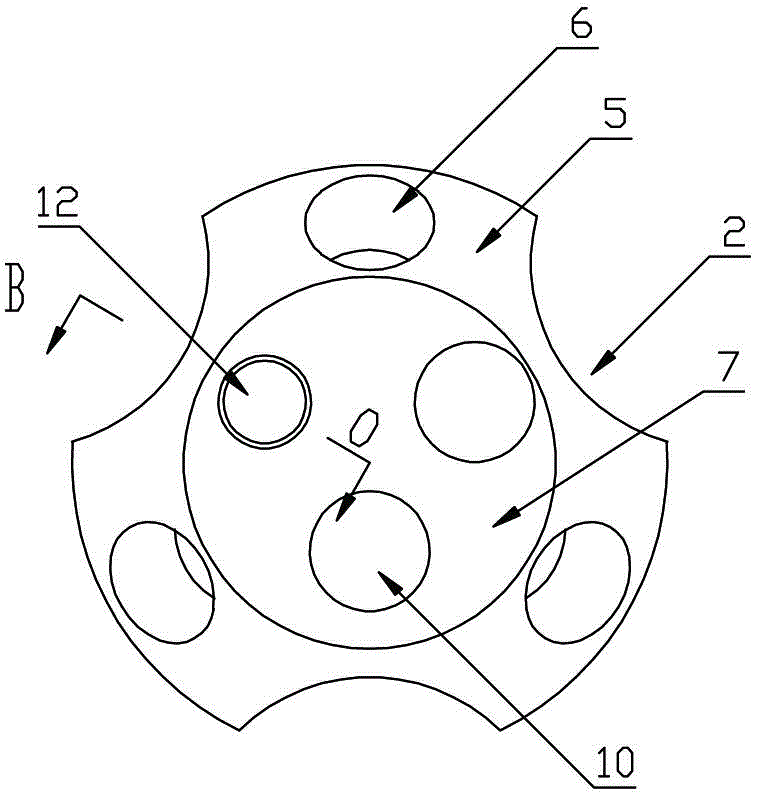

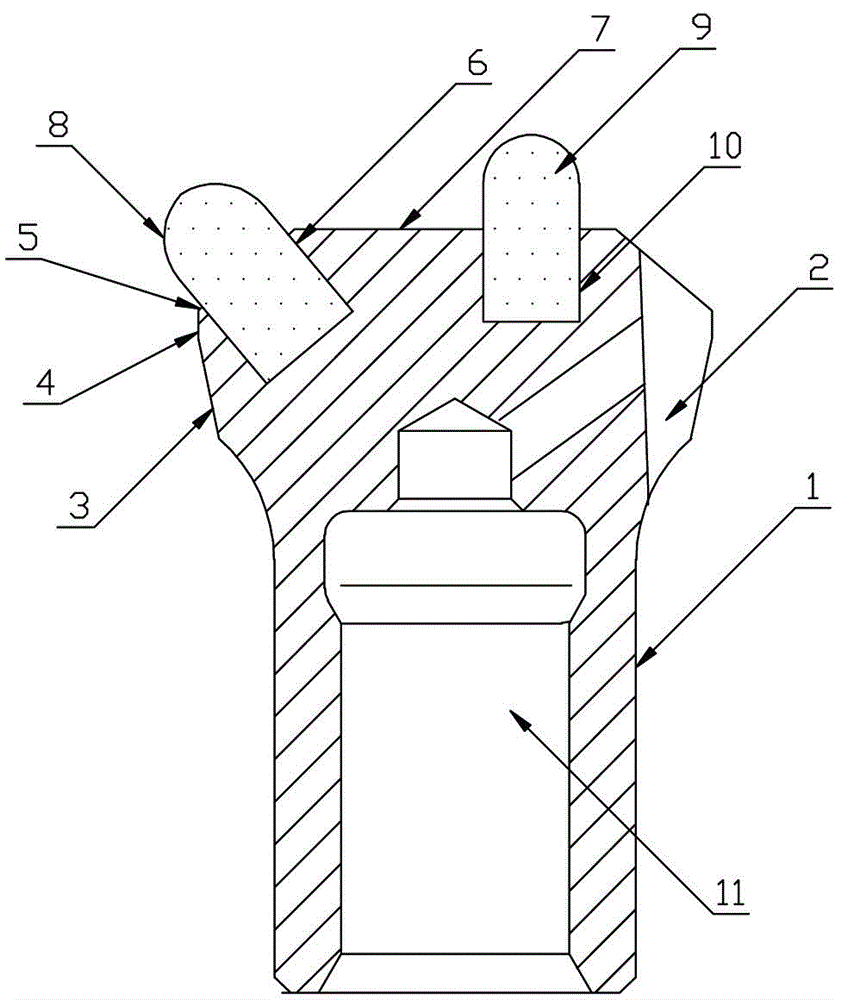

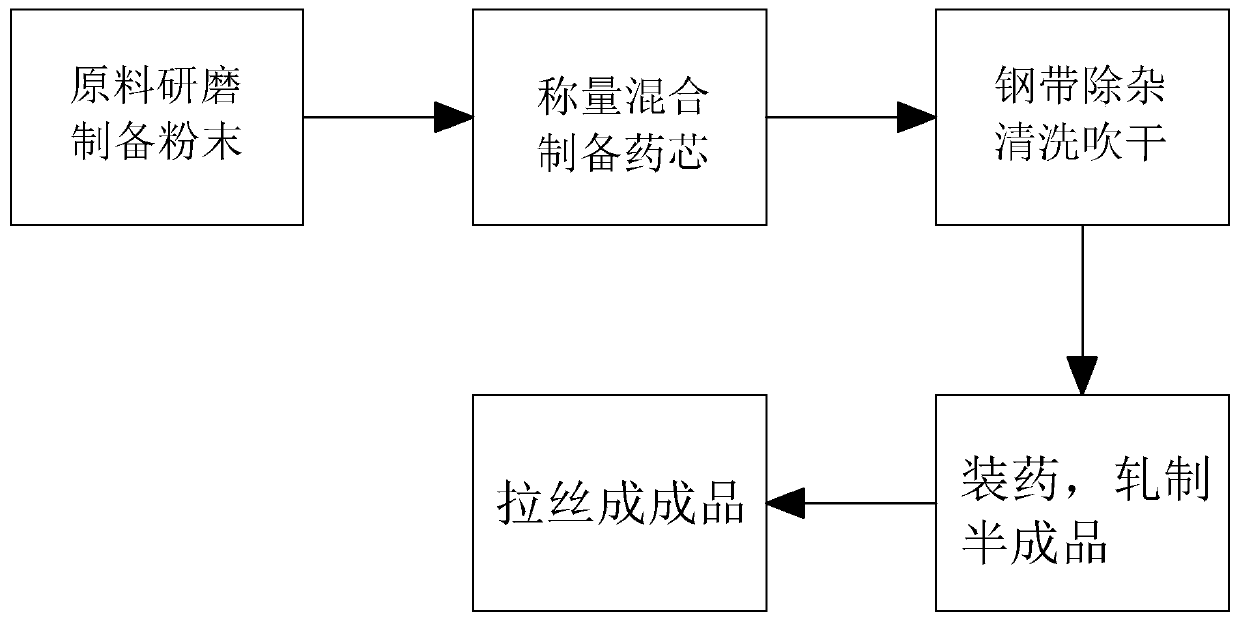

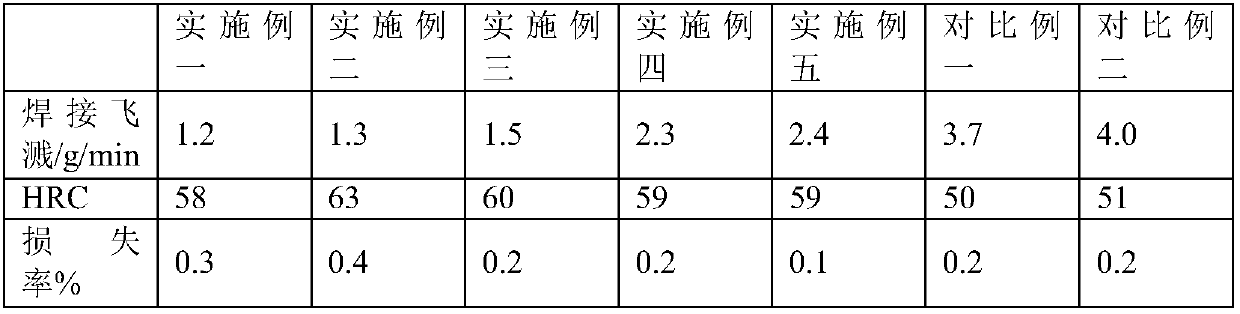

ActiveCN107877033AReduce the amount of splashRealize the role of stabilizing the arcWelding/cutting media/materialsSoldering mediaManganeseHardness

Disclosed is a flux-cored wire. The flux-cored wire includes a mild-carbon steel strip and a flux core. The flux core includes, by weight, 3.0-5.0% of carbon, 0.5-2.5% of manganese, 0.5-2.5% of silicon, 22.0-27.0% of chromium, 2.0-4% of sodium salt, 0.2-0.4% of kali salt, 4-8% of slagging constituents, 9-16% of deoxidizing agents and the balance iron. The flux-cored wire is convenient to process,and meanwhile, during welding, the splash range is small; waste of raw materials is greatly reduced; the production safety hazard is also weakened, so that production efficiency is greatly improved; in addition, a fusion layer after flux-cored welding is just high chromium cast iron, and the high chromium cast iron has high hardness; and therefore, the service life of the fusion layer is greatly prolonged.

Owner:天津沃盾耐磨材料有限公司

Method for direct production of high-grade zinc oxide from zinc material containing high chlorine and fluorine

ActiveCN103834819ASolve process problemsReduce generation costProcess efficiency improvementCokeExhaust fumes

The invention discloses a method for direct production of high-grade zinc oxide from a zinc material containing high chlorine and fluorine. The method comprises the following steps of 1, mixing the zinc material containing high chlorine and fluorine, furnace surface ash and smokeless pulverized coal according to a certain ratio, carrying out crushing, adding a binder into the crushed materials, carrying out mixing, and carrying out rolling to obtain balls, 2, after bed coke in a zinc oxidation furnace is red and hot, putting the balls naturally air-dried for two days into the zinc oxidation furnace, carrying out blasting, and discharging waste gas for 10-15min, wherein a blast volume is controlled in 20-30% the total air volume, and 3, after switching out, increasing a blast volume into the zinc oxidation furnace, heating the zinc oxidation furnace to a temperature above 1050 DEG C in 0.5h, controlling an exhaust volume so that an aluminum pipe section furnace gas temperature is in a range of 450-550 DEG C and a bag chamber section furnace gas temperature is in a range of 180-250 DEG C, and carrying out smelting for 1.5-2.5h. The method has wide raw material selection approach and range, a low production cost and a high metal recovery rate and realizes zinc oxide content of 98-99%.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Special high-temperature slag forming agent for refining aluminum titanium boron alloy

The invention relates to the field of refining of intermediate alloy of aluminum, in particular to a special high-temperature slag forming agent for refining an aluminum titanium boron alloy. The special high-temperature slag forming agent comprises the following components in parts by weight: 13-18 parts of MgF2, 22-27 parts of NaF; 16-25 parts of Na3AlF6, 20-28 parts of CaF2, and 12-15 parts of Na2SiF6. Through the utilization of the slag forming agent disclosed by the invention, fluorides and oxides in the aluminum titanium boron alloy can be well removed, and the slag forming effect is good, so that the content of impurities in the alloy can be greatly reduced, the cleanliness and the quality of the alloy are improved, and the refining ability of the aluminum titanium boron alloy is improved; and besides, the price of the slag forming agent disclosed by the invention is nearly equal to that of a common slag forming agent, so that no extra expenses are not additionally generated.

Owner:山东滨州华创金属有限公司

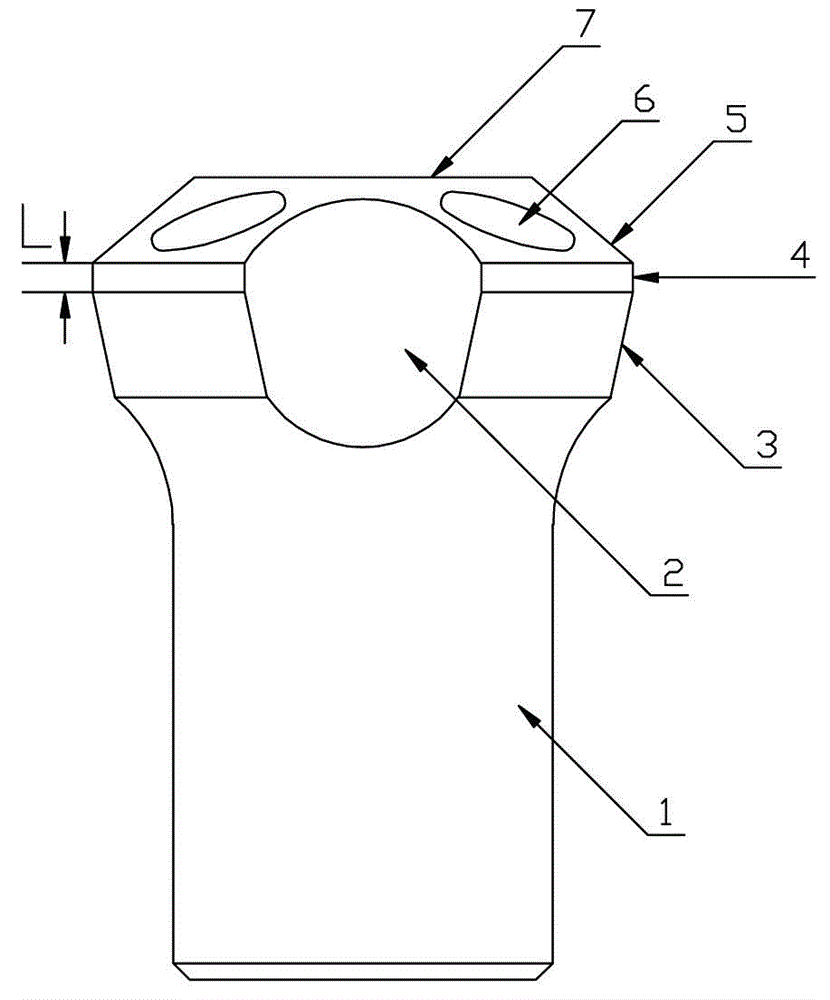

Reinforced type drilling drill bit with gauge protection step

The invention relates to drilling tools, in particular to a reinforced type drilling drill bit with a gauge protection step. The reinforced type drilling drill bit is provided with a trouser body, a blind hole with a downward opening is formed in the trouser body, the lower section of the blind hole is a threaded hole, the front end of the trouser body is a conic head shrinking forwards, multiple arc-shaped grooves are formed in the periphery of the head, multiple inclined holes are formed in the conic face of the head, the inclined holes and the arc-shaped grooves are staggered and alternated, each alloy tooth is embedded in the corresponding inclined hole, multiple perpendicular holes are formed in the end face of the head, and each alloy tooth is embedded in the corresponding perpendicular hole. The reinforced type drilling drill bit is characterized in that at least one flushing hole is drilled in the end face of the head so as to be communicated with the blind hole in the trouser body, the head and the trouser body are in transitional connection through two sections of structures, the front section is a gauge protection step cylindrical section connected with the head, and the rear section is a reversed cone connected with the trouser body. By the adoption of the reinforced type drilling drill bit, the problems that teeth of an existing drill bit are broken and fall in the early stage and the residue discharging effect is not ideal are well solved and the reinforced type drilling drill bit is widely applied to mountain cutting and rock drilling engineering.

Owner:武穴市长江工具股份有限公司

Stainless steel slagging and degassing refining agent

This invention relates to a rustless steel slag-forming and degassing agent, which is specifically a casting accessory material to clean up rustless steel molten steel surface and improve rustless steel quality, and belong to metal surface treatment technique area in foundry industry. This agent mainly comprises 70-80 wt% of dolomite, 10-15 wt% of aluminum dust and 6-15 wt% of fluor. The components are mixed completely in normal temperature and packed to completed product. This invention possesses the properties of increasing life of brasque to more than 200 times; improving slag-forming ability to decrease endermic points, decrease surface points and pocks of buffing surface and increase rate of finished products and improving thermal insulation and degasification by floating constantly on the surface of molten steel, in which molten steel is prevented to contact with air and oxygenized, suck in hydrogen and nitrogen and interfused with foreign substance, so as to ensure cleaner molten steel higher property.

Owner:张华静

Refining agent for spring steel production furnace external refining and preparation method thereof

The invention discloses a refining agent for spring steel production furnace external refining and a preparation method thereof. The refining agent is composed of the following raw materials in parts by weight: 20-30 parts of calcium oxide, 8-10 parts of calcium fluoride, 5-8 parts of barium chloride, 5-8 parts of magnesium chloride, 10-15 parts of scrap aluminum powder, 5-10 parts of magnesium oxide, 3-5 parts of rare earth, 5-8 parts of diatom ooze, 10-15 parts of bentonite and 6-8 parts of pyrauxite. The preparation method comprises the following steps: respectively crushing the raw materials into 10-30mm particles with a crusher, weighing the raw materials according to parts by weight, uniformly mixing with a ball mill, screening the uniformly mixed raw materials with a 100-mesh sieve, and finally, baking the screened mixture at 80-100 DEG C. The refining agent has the advantages of high chemical stability, favorable desulfurization and dephosphorization effect, favorable slaggability and high degassing and impurity-removal capacity, and obviously enhances the mechanical properties and corrosion resistance of the spring steel. The method has the advantages of simple preparation technique and low cost.

Owner:江苏古沙农业科技发展有限公司

A kind of flux-cored welding wire and its preparation method

ActiveCN107877033BReduce the amount of splashRealize the role of stabilizing the arcWelding/cutting media/materialsSoldering mediaManganeseHardness

Disclosed is a flux-cored wire. The flux-cored wire includes a mild-carbon steel strip and a flux core. The flux core includes, by weight, 3.0-5.0% of carbon, 0.5-2.5% of manganese, 0.5-2.5% of silicon, 22.0-27.0% of chromium, 2.0-4% of sodium salt, 0.2-0.4% of kali salt, 4-8% of slagging constituents, 9-16% of deoxidizing agents and the balance iron. The flux-cored wire is convenient to process,and meanwhile, during welding, the splash range is small; waste of raw materials is greatly reduced; the production safety hazard is also weakened, so that production efficiency is greatly improved; in addition, a fusion layer after flux-cored welding is just high chromium cast iron, and the high chromium cast iron has high hardness; and therefore, the service life of the fusion layer is greatly prolonged.

Owner:天津沃盾耐磨材料有限公司

The Method of Shortening the Time of Smelting Ferrovanadium

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A new environmentally friendly synthetic slagging material

ActiveCN105734197BGood slagging performanceWide variety of sourcesManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention provides a novel environment-friendly synthetic slag forming material which comprises the following raw material components in parts by weight: 11-14 parts of CaO, 5-25 parts of aluminum ash powder, 70-73 parts of SiO2, 1-2 parts of MnO, 8-10 parts of FeO and 2-5 parts of Y2O3. The novel environmental-friendly synthetic slag forming material is environment-friendly, superior in slag forming performance, and wide in raw material sources, belongs to a resource recycling material, is low in pollution on molten steel during the steel-making using process, and small in generated slag quantity, can remarkably improve the comprehensive performance of a steel-making slag system, and improves the quality of molten steel. The novel environment-friendly synthetic slag forming material, namely a slag former, belongs to comprehensive utilization of industrial wastes, and is reliable in process, low in cost, and profitable.

Owner:山东济钢泰航合金有限公司

A kind of molten steel refining flux and its manufacturing method

ActiveCN103509910BLow melting pointPromote meltingProcess efficiency improvementProduction rateChemical composition

The invention provides a molten steel refining fluxing agent and its making method. The fluxing agent comprises the following chemical components by weight: 5%-10% of CaO, 20%-30% of MgO, 2%-5% of CaF2, 25%-35% of Al2O3, 2%-5% of B2O3, 15%-25% of SiO2, and the balance less than 20% of inevitable impurities. The making method comprises: 1) conducting burdening: mixing 100-200 mesh industrial raw material powder containing CaO, Al2O3, SiO2, MgO, B2O3 and CaF2 uniformly according to the weight percentage of the fluxing agent; 2) performing ball making: adding 5%-10% of water glass, mixing them evenly, and pressing the mixture into a spherical material; 3) subjecting the spherical material to baking drying for 1-2h at 250-300DEG C, and then cooling the spherical material to room temperature for 4-6h; and 4) conducting screening to obtain the material with a particle size of 10-40mm and a weight content of greater than or equal to 95%, i.e. a finished product. The molten steel refining fluxing agent provided by the invention lowers the melting point of refining slag, shortens the slagging time, improves the refining production rate, and does not pollute the molten steel, and slightly erodes the furnace lining. Compared with the use of fluorite, the production cost is low, and the environmental pollution is small.

Owner:ANGANG STEEL CO LTD

Laser cladding powder for 1cr15ni4mo3n steel and its preparation method

ActiveCN106555126BHigh bonding strengthLess metallurgical defectsMaterial nanotechnologyMetallic material coating processesRare earthToughness

Owner:国营芜湖机械厂

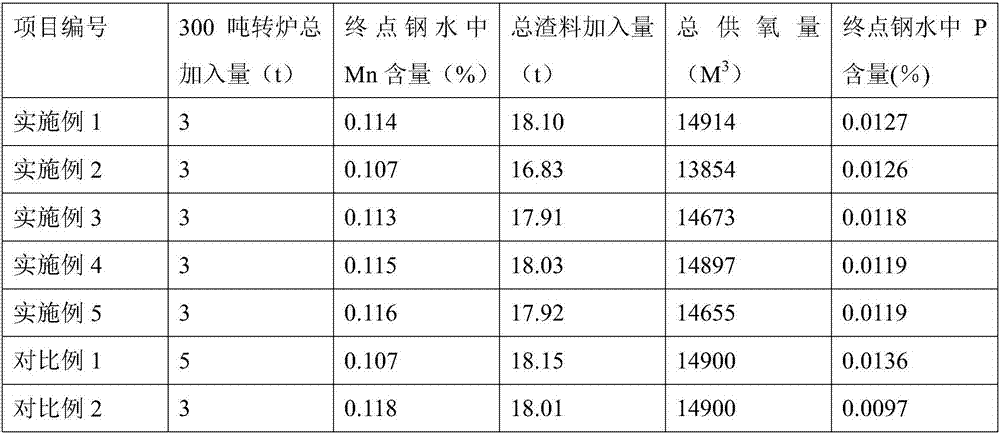

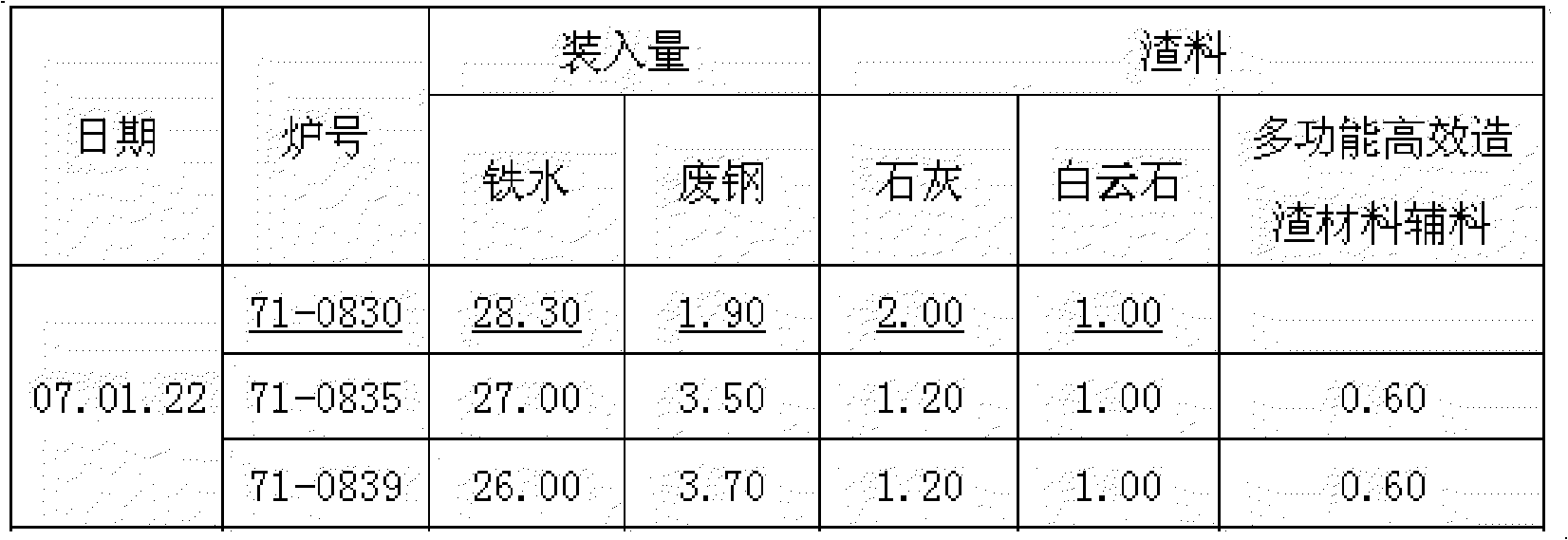

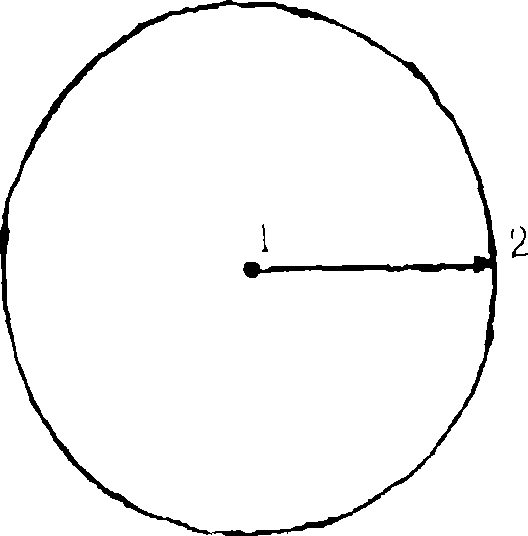

Method for applying scorification material supplementary material to convertor steelmaking

The invention relates to a method for applying auxiliary material of slagging material in the converter steel-making, pertaining to the field of metallurgy. The auxiliary material of the slagging material can be served as a dephosphorizing agent and a slag-melted agent, including: 8.0-9.5 portions by weight of converter steel slag and 0.5-2.0 portions by weight of additive, wherein, the additive includes 5.00-10.00 percent by weight of Na2CO3, 70.00-80.00 percent by weight of FeO and 10.00-20.00 percent by weight of BaCO3. The production of the auxiliary material of the slagging material by adding the additive into the converter steel slag has a plurality of effects, such as realization of recycling of the converter steel slag, which can not only reduce the total amount of waste slag fromsteel-making but reduce consumption of the existing slagging material such as lime and dolomite, improve slagging performance, increase dephosphorization rate by 5.00 to 8.00 percent, reduce the steel slag TFe by 3.00 to 5.00 percent after the steel smelting as well as the blowing damage by about 0.3 percent and increase the metal yield.

Owner:攀钢集团成都钢铁有限责任公司

A method for direct production of high-grade zinc oxide from zinc materials containing high chlorine and fluorine

ActiveCN103834819BSolve process problemsReduce generation costProcess efficiency improvementFurnace temperatureAir volume

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

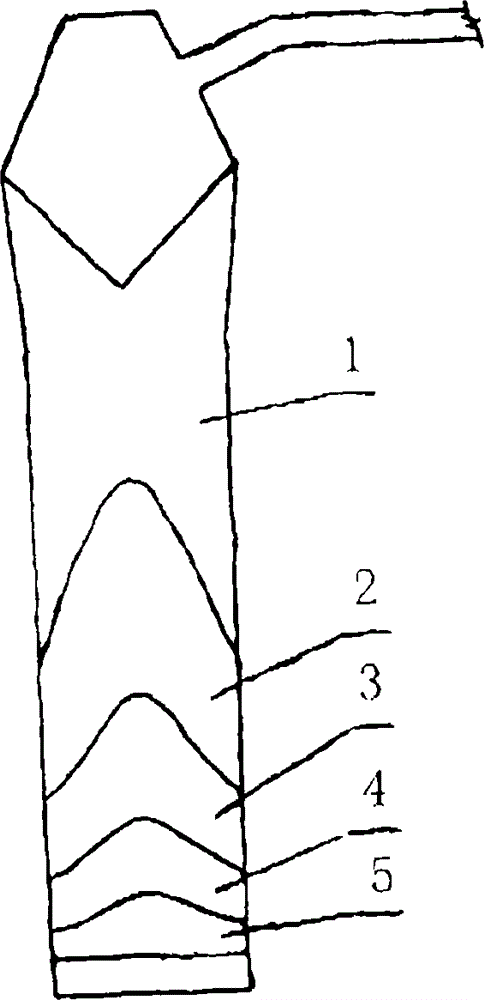

Method of controlling temperature of energy-saving environment-friendly laterite-nickel ore smelting shaft furnace through aluminothermic process

The invention discloses a method of controlling the temperature of an energy-saving environment-friendly laterite-nickel ore smelting shaft furnace through an aluminothermic process, and belongs to the production field of laterite-nickel ores. The method of controlling the temperature of the energy-saving environment-friendly laterite-nickel ore smelting shaft furnace through the aluminothermic process is characterized in that furnace burden smelting is divided into five areas, namely a preheating area, a restoring area, a combustion area, a smelting area and a separation area, then temperature measurement is carried out, and after a peripheral temperature value is measured, a monitoring expert system carries out contrastive analysis and calculates a variation value of the central temperature. The needed absorption heat is calculated through the temperature variation value, the addition quantity of aluminum particles is affirmed, blown-in oxygen and oxygen in raw ores are captured due to the high calorific value of aluminum, aluminum oxide is generated and enters a slag flow, and the temperature in a reaction area is improved rapidly to reach the standard reaction temperature. According to the method of controlling the temperature of the energy-saving environment-friendly laterite-nickel ore smelting shaft furnace through the aluminothermic process, a monitoring expert system is automatic, the reaction is timely, after the aluminum particles are added into crude fuel, the temperature is improved rapidly, the production efficiency is high, the recovery rate of metallic nickel is improved at the same time, and great economical benefits are achieved.

Owner:FUSHUN HANKING DRI CO LTD

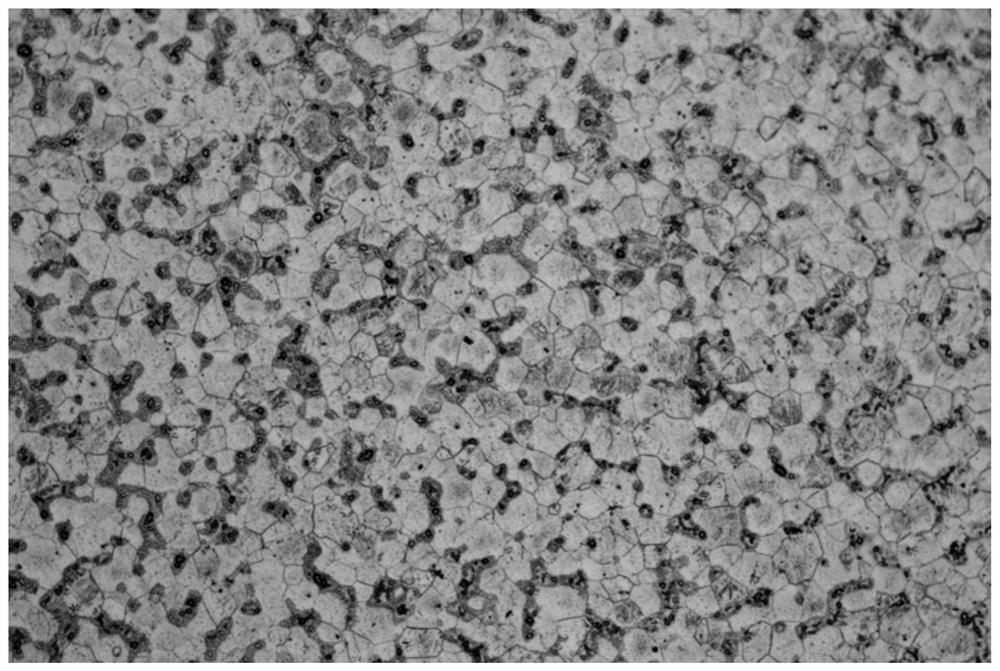

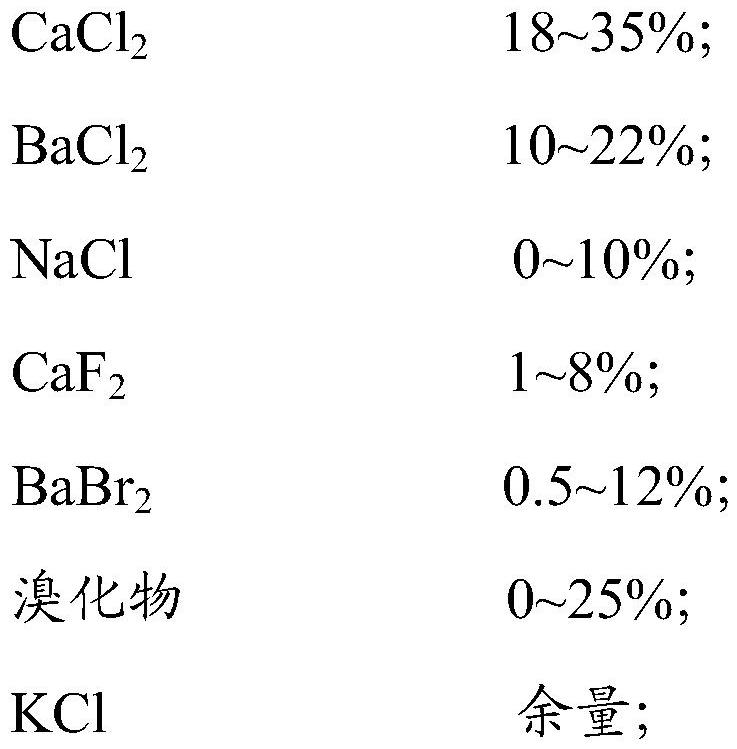

Bromine-containing refining agent for rapid sedimentation of rare earth magnesium alloy, preparation method and application

The invention discloses a bromine-containing refining agent for rapid sedimentation of a rare earth magnesium alloy. The bromine-containing refining agent comprises the following components: CaCl2, BaCl2, NaCl, CaF2, BaBr2, bromide and KCl. According to the refining agent, the content of a specific gravity agent is increased, the density of a flux is improved, part of bromine salt is added to serve as a fluxing agent, the spreadability, slagging capacity and refining capacity of the refining agent are improved, inclusions in magnesium melt can be fully removed within the short standing time after refining, flux inclusions are not generated, the grain refining effect is not affected, and the refining effect is good. And the refining process is effectively shortened, and the method is particularly suitable for refining treatment of the magnesium alloy with the rare earth content and high melt viscosity and density. The invention further discloses a preparation method and application of the bromine-containing refining agent.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

A tig welding method for improving welding penetration and preventing back oxidation

ActiveCN109604868BIncrease coverageHigh affinityArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld seam

A TIG welding method that improves welding penetration and prevents back oxidation. The invention can greatly increase TIG welding penetration, prevent weld back oxidation, improve weld slag inclusions, pores, weld penetration and other forming defects, and achieve 5-10mm medium Thick stainless steel is welded and formed at one time. The method saves the cumbersome multi-layer welding process, shortens the production cycle, reduces energy consumption, saves cost, and greatly improves the forming quality of TIG primary welding.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag

ActiveCN102796879BHigh degree of resource utilizationEfficient separationProcess efficiency improvementIron powderMixed materials

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

A kind of refining agent for producing spring steel for refining outside the furnace and preparation method thereof

The invention discloses a refining agent for spring steel production furnace external refining and a preparation method thereof. The refining agent is composed of the following raw materials in parts by weight: 20-30 parts of calcium oxide, 8-10 parts of calcium fluoride, 5-8 parts of barium chloride, 5-8 parts of magnesium chloride, 10-15 parts of scrap aluminum powder, 5-10 parts of magnesium oxide, 3-5 parts of rare earth, 5-8 parts of diatom ooze, 10-15 parts of bentonite and 6-8 parts of pyrauxite. The preparation method comprises the following steps: respectively crushing the raw materials into 10-30mm particles with a crusher, weighing the raw materials according to parts by weight, uniformly mixing with a ball mill, screening the uniformly mixed raw materials with a 100-mesh sieve, and finally, baking the screened mixture at 80-100 DEG C. The refining agent has the advantages of high chemical stability, favorable desulfurization and dephosphorization effect, favorable slaggability and high degassing and impurity-removal capacity, and obviously enhances the mechanical properties and corrosion resistance of the spring steel. The method has the advantages of simple preparation technique and low cost.

Owner:江苏古沙农业科技发展有限公司

Method for shortening ferrovanadium smelting time

ActiveCN111286610AShorten smelting timeProduct quality is not affectedSmelting processFerrovanadium alloy

The invention relates to a method for shortening ferrovanadium smelting time, and belongs to the technical field of vanadium metallurgy. The method for smelting ferrovanadium comprises the following steps that vanadium trioxide, vanadium-containing dust and lime are mixed according to a certain ratio to prepare a mixture; water is added to prepare a wet material, and molding is performed to prepare wet aggregates; the wet aggregates are dried to obtain cold consolidation flux type vanadium-containing pellets; and the dried cold consolidation flux type vanadium-containing pellets, flake vanadium, aluminum particles, scrap iron and lime are added into a ferrovanadium furnace for electrified smelting to obtain a ferrovanadium alloy. According to the method, on the premise that a subsequent conventional stirring method is not changed, the purpose of shortening the smelting time can be achieved, the product quality is not affected, and the effect of reducing flying dust in the field environment in the feeding process and the smelting process is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of scouring agent for aluminum and aluminum alloy

The invention relates to a preparation method of a scouring agent for aluminum and an aluminum alloy, which comprises the following steps: firstly, selecting ingredients according to the following percentages by weight: 30-85% of NaCl, 5-40% of Na2SiF6, 5-40% of Na2SO4, 2-20% of CaF2 and 0.5-10% of C6Cl6; uniformly mixing and fully stirring the selected ingredients; placing the mixture into a crucible, carrying out overheat melting to eliminate crystal water, and preserving the temperature for 30-60 minutes; and finally, processing after cooling to obtain the scouring agent. The method has the advantages of simple process and low cost. The prepared scouring agent does not contain sylvite, so that sylvite can not be introduced into the scouring and purifying treatment procedures, and therefore, an aluminum electrolysis cell can not be seriously corroded as a result of the introduction of sylvite when aluminum ash is directly recycled in the cell.

Owner:包头市一禾稀土铝业科技材料有限公司

Method for controlling energy saving and environment protecting laterite nickel ore smelting shaft furnace temperature by silicothermic process

Belonging to the field of laterite nickel ore production, the invention relates to a method for controlling the temperature of an energy saving and environment protecting laterite nickel ore smelting shaft furnace by a silicothermic process. The method is characterized in that: first, furnace charge smelting is divided into five areas, i.e. preheating, reduction, combustion, melting and separation, then temperature measuring is conducted, after measuring the surrounding temperature value, contrastive analysis is carried out by a monitoring expert system, and a center temperature variation value is calculated. The needed absorption heat is calculated through the temperature variation value, and accordingly, the adding amount of ferrosilicon can be determined. The high calorific value of silicon can be utilized to capture blown oxygen and oxygen in raw ore. The generated silicon oxide enters a slag flow, and the reaction area temperature can be rapidly raised to reach the standard reaction temperature. The expert monitoring system involved in the method is automated and can make timely response. After ferrosilicon is added to the raw materials, temperature rise become rapid, the production efficiency is high, and meanwhile, the recovery rate of metallic nickel is improved, so that considerable economic benefits can be achieved.

Owner:FUSHUN HANKING DRI CO LTD

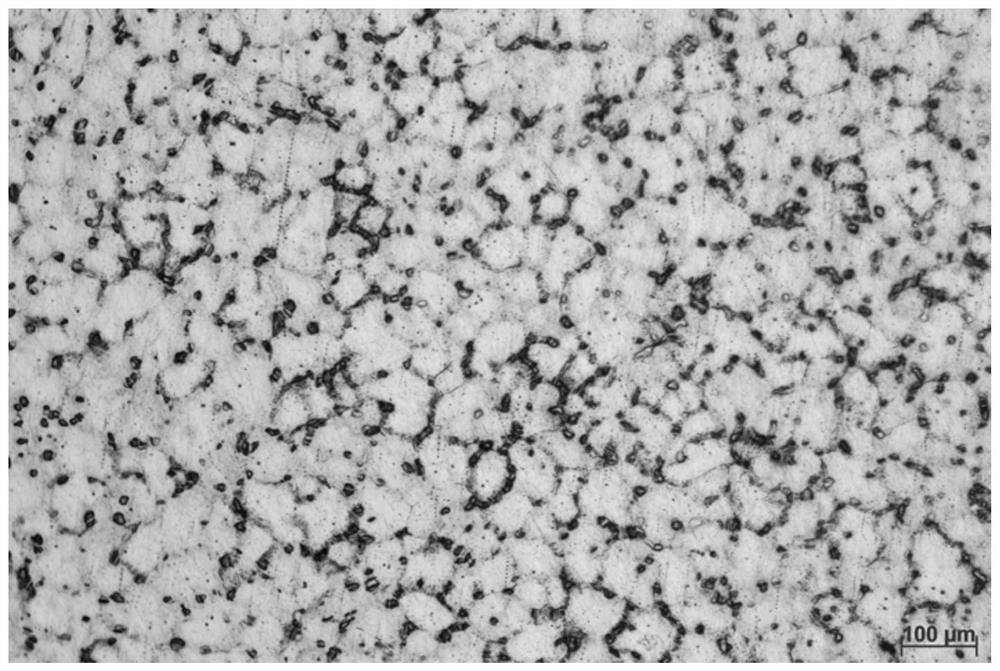

A steelmaking slag material

ActiveCN103834765BHigh viscosityViscosity adjustmentProcess efficiency improvementSteelmakingRefractory

The invention discloses a steelmaking slag-making material, and the slag-making material comprises the following materials in parts by weight: 65-75% of lime, 9-13% of fluorite powder, 16-20% of alumina, 6-8% of dolomite, and impurities. The lime containing in the slag-making material is a necessary ingredient for slag making, modification and the like in steelmaking production, helps to improve the furnace slag basicity, and ensures a good deoxidation effect, the alumina can adjust the slag system melting point, with increasing of the alumina, the viscosity of slag may increase, by control of the content between 16 and 20, a better slag-making effect can be achieved, by addition of the fluorite powder, the slag bonding degree can be reduced, and bonded slag on steel ladles can be prevented, the fluorite powder can accelerate the dissolution of the lime, and improve the furnace slag liquidity, magnesia contained in the dolomite can prolong the life of a fire resistant material, the fluorite powder and the alumina used in the slag-making material are slag materials used by electroslag remelting, and experiments show that the used fluorite powder and the alumina as the steelmaking slag-making material can exhibit better steelmaking slag-making effect, and play the role of turning waste materials into things of value.

Owner:TIANGONG AIHE SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com