A kind of flux-cored welding wire and its preparation method

A flux-cored welding wire and flux-cored technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as unfavorable environmental protection, potential safety hazards, and easy occurrence of splashes, so as to reduce the number of spark splashes, reduce the possibility of Good slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

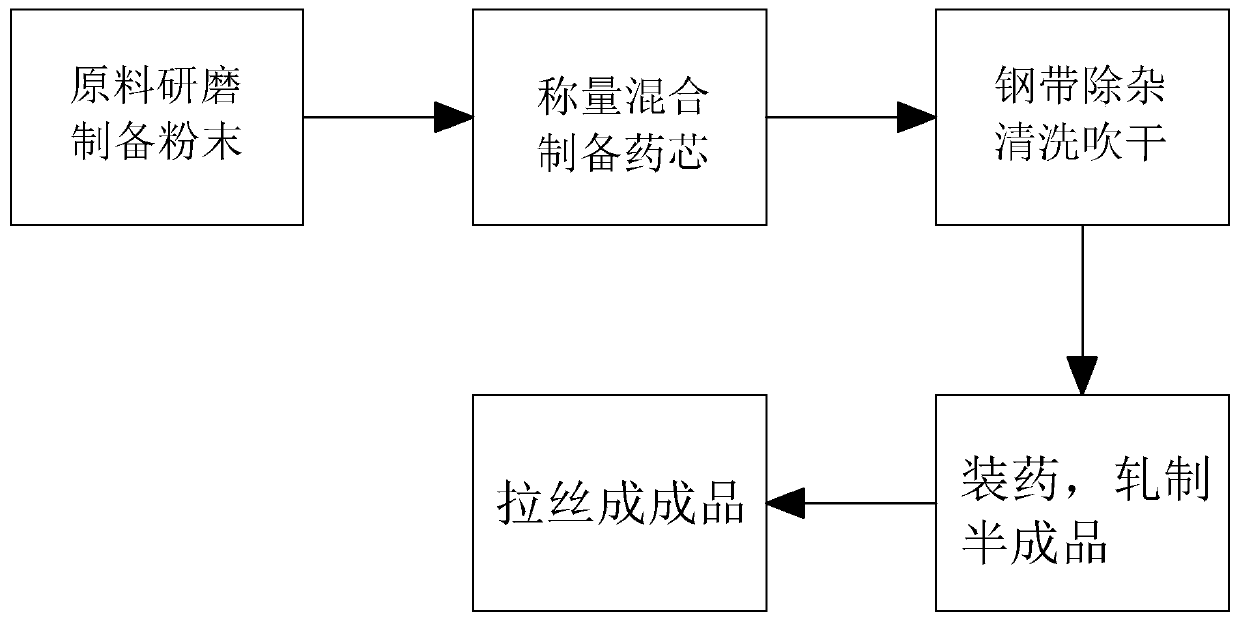

Method used

Image

Examples

Embodiment 1

[0036] S1, carbon, manganese, silicon, chromium, sodium salt, potassium salt, ferrite, Al-Ti-Ca composite deoxidizer and iron are made into powder respectively in advance;

[0037] S2. Weigh 3kg carbon, 0.5kg manganese, 0.5kg silicon, 22kg chromium, 1kg sodium carbonate, 1kg sodium silicate, 0.1kg potassium carbonate, 0.1kg potassium silicate, 4kg bauxite, 9kg Al-Ti-Ca compound Add deoxidizer and 58.8kg iron into the mixer for uniform mixing;

[0038] S3. Before rolling, first clean off the grease, dust and sundries on the low-carbon steel strip, and then dry it with high-temperature nitrogen at a wind speed of 15m / s to 20m / s.

[0039] S4. Roll the low-carbon steel strip into a "U" shape first, and fill it with uniformly mixed medicinal powder, then roll the low-carbon steel strip into an "O", and seal the medicinal powder in the low-carbon steel strip to obtain Semi-finished welding wire;

[0040] S5. Apply a lubricating coating on the surface of the semi-finished welding w...

Embodiment 2

[0042] S1, carbon, manganese, silicon, chromium, sodium salt, potassium salt, ferrite, Al-Ti-Ca composite deoxidizer and iron are made into powder respectively in advance;

[0043] S2. Weigh 5kg carbon, 2.5kg manganese, 2.5kg silicon, 27kg chromium, 4kg sodium carbonate, 0.1kg potassium carbonate, 0.2kg potassium silicate, 0.1kg potassium titanate, 8kg bauxite, 16kg Al-Ti-Ca Add composite deoxidizer and 34.6kg iron into the mixer for uniform mixing;

[0044] S3. Before rolling, first clean off the grease, dust and sundries on the low-carbon steel strip, and then dry it with high-temperature nitrogen at a wind speed of 15m / s to 20m / s.

[0045] S4. Roll the low-carbon steel strip into a "U" shape first, and fill it with uniformly mixed medicinal powder, then roll the low-carbon steel strip into an "O", and seal the medicinal powder in the low-carbon steel strip to obtain Semi-finished welding wire;

[0046] S5. Apply a lubricating coating on the surface of the semi-finished we...

Embodiment 3

[0048] S1, carbon, manganese, silicon, chromium, sodium salt, potassium salt, ferrite, Al-Ti-Ca composite deoxidizer and iron are made into powder respectively in advance;

[0049] S2. Weigh 4kg carbon, 1.5kg manganese, 1.5kg silicon, 24.5kg chromium, 3kg sodium silicate, 0.2kg potassium carbonate, 0.1kg potassium titanate, 6kg bauxite, 12.5kg Al-Ti-Ca composite deoxidizer And 46.7kg iron joins in the mixer and mixes evenly;

[0050] S3. Before rolling, first clean off the grease, dust and sundries on the low-carbon steel strip, and then dry it with high-temperature nitrogen at a wind speed of 15m / s to 20m / s.

[0051] S4. Roll the low-carbon steel strip into a "U" shape first, and fill it with uniformly mixed medicinal powder, then roll the low-carbon steel strip into an "O", and seal the medicinal powder in the low-carbon steel strip to obtain Semi-finished welding wire;

[0052] S5. Apply a lubricating coating on the surface of the semi-finished welding wire, and draw the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com