Apparatus for producing zonal polycrystalline silicon by edge limited silicon film growth method

An edge-limited, polysilicon technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of complex ring discharge channel structure, increased production difficulty, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

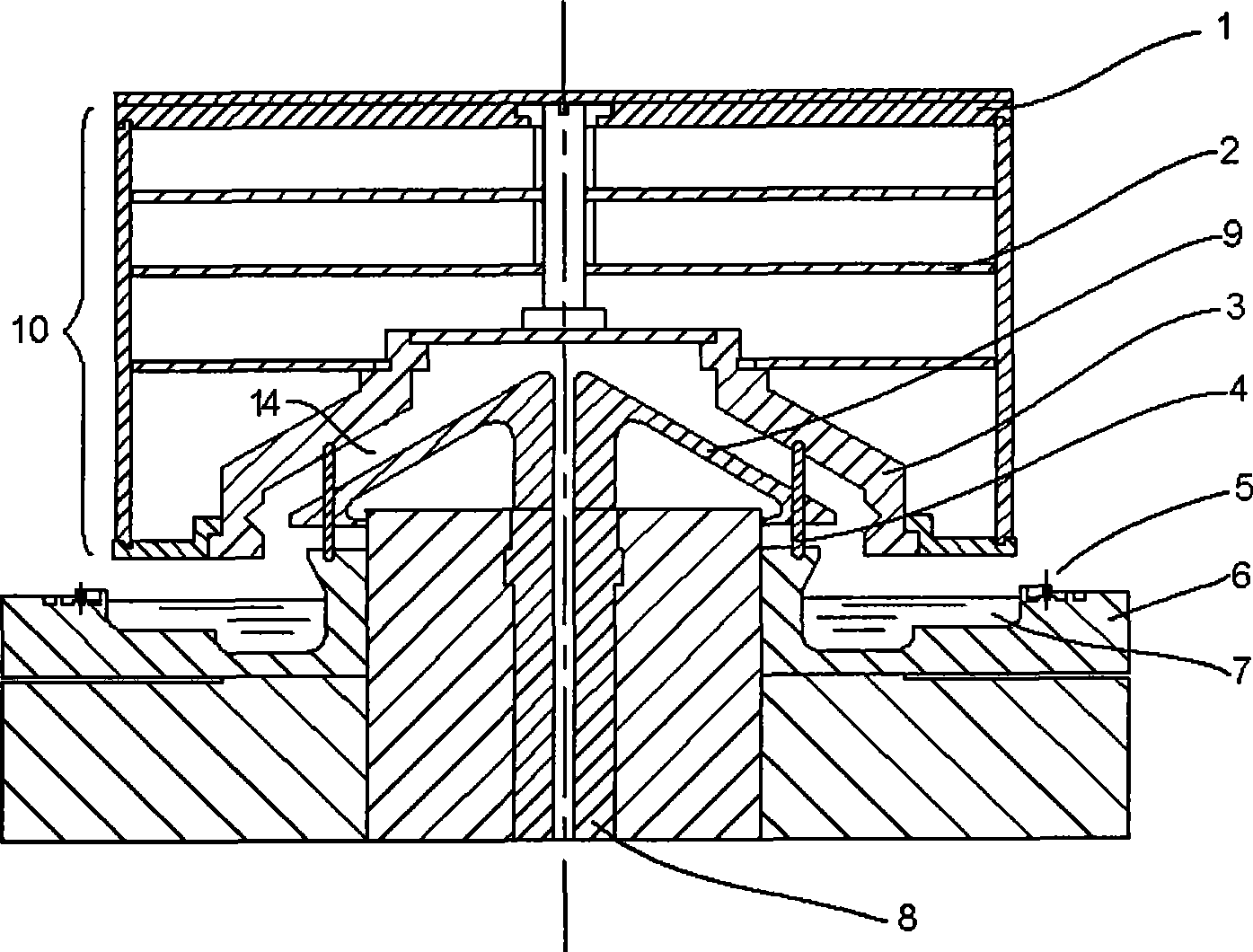

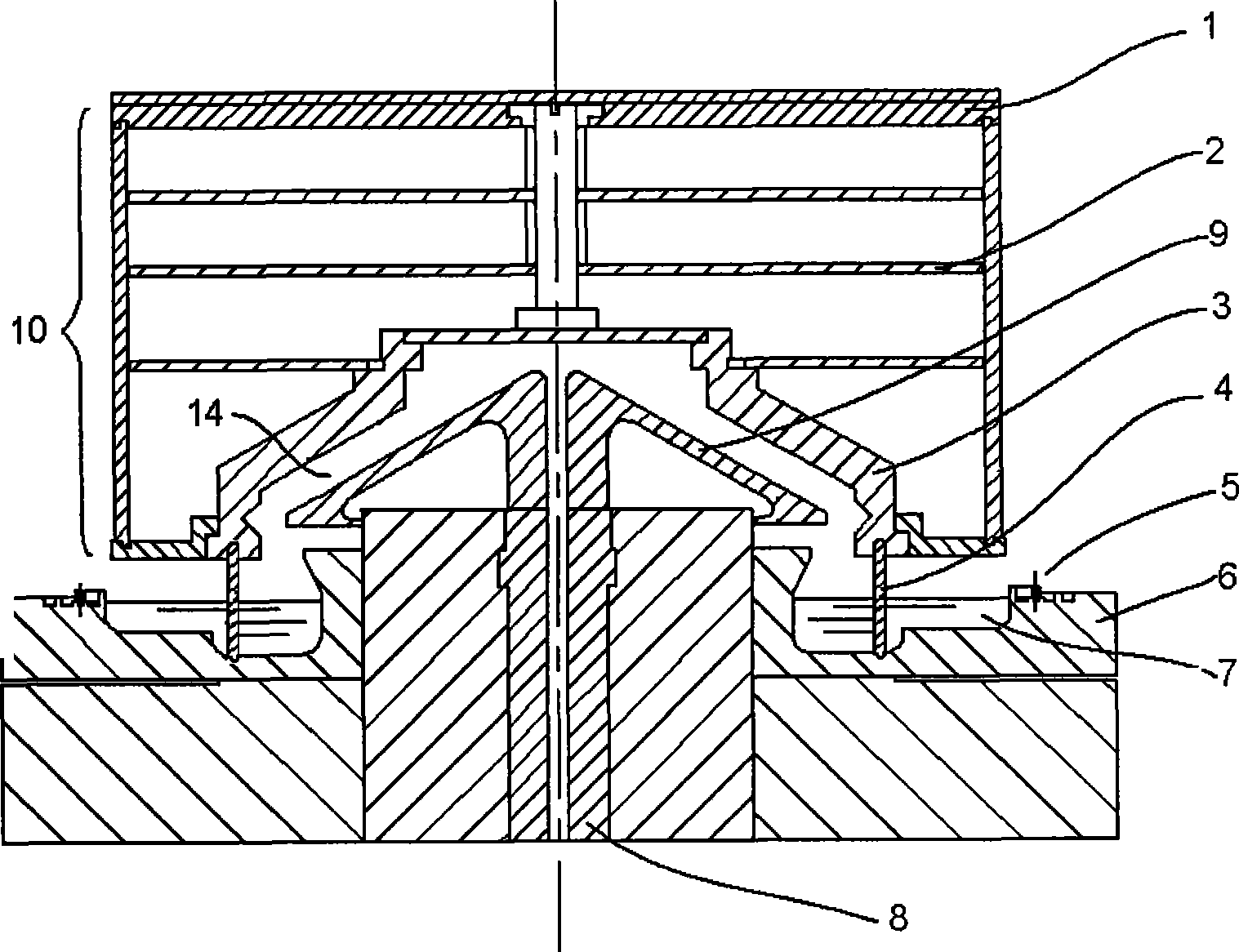

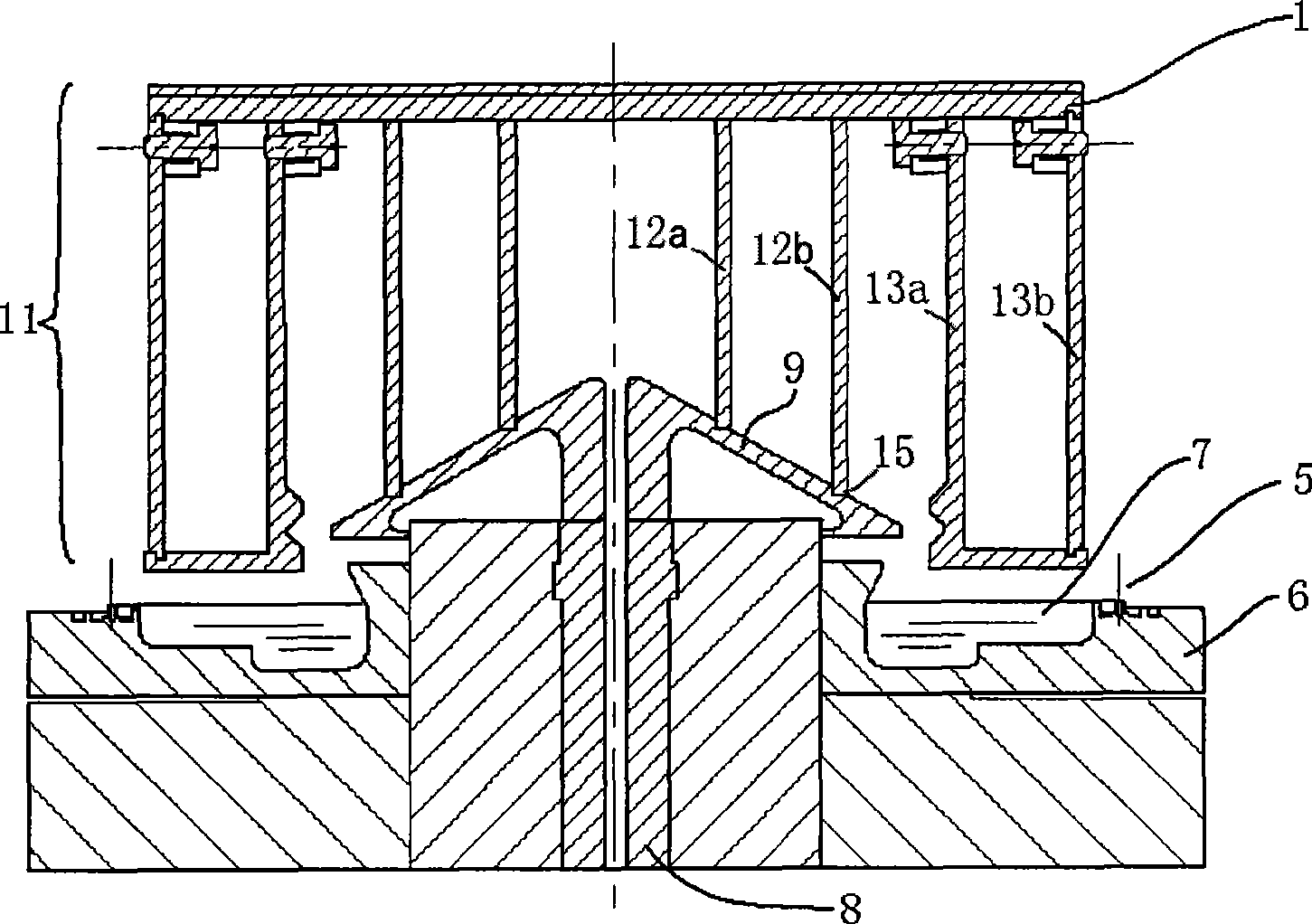

[0020] see image 3 , the present invention is used in the edge defined silicon film growth method to produce strip-shaped polysilicon device, including a tapered guide 9 with a central sleeve 8 and a superstructure 11 supported on the top surface of the tapered guide 9 .

[0021] The superstructure 11 includes an inner sleeve set coaxially arranged with the central casing 8, an outer sleeve set coaxially arranged on the periphery of the inner sleeve set and a top plate 1 for sealing the tops of the inner sleeve set and the outer sleeve set.

[0022] The inner sleeve group is composed of two coaxially arranged inner sleeves 12a and 12b nested in each other. Both the inner sleeve 12a and the inner sleeve 12b are cylindrical sleeves with several feet 15 on the bottom edge. , The top surface of the tapered guide 9 is provided with a branch for accommodating the legs 15, and the cross-sectional shape of the branch matches the cross-sectional shape of the legs 15.

[0023] The out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com