Molten steel refining fluxing agent and its making method

A manufacturing method and a flux technology, which are applied in the field of molten steel refining fluxes, can solve the problems of less natural resources, limited usage, erosion of fluorite on ladle lining, etc., achieve stable and controllable composition, reduce environmental pollution, and help The effect of slag melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below by embodiment the present invention will be further described.

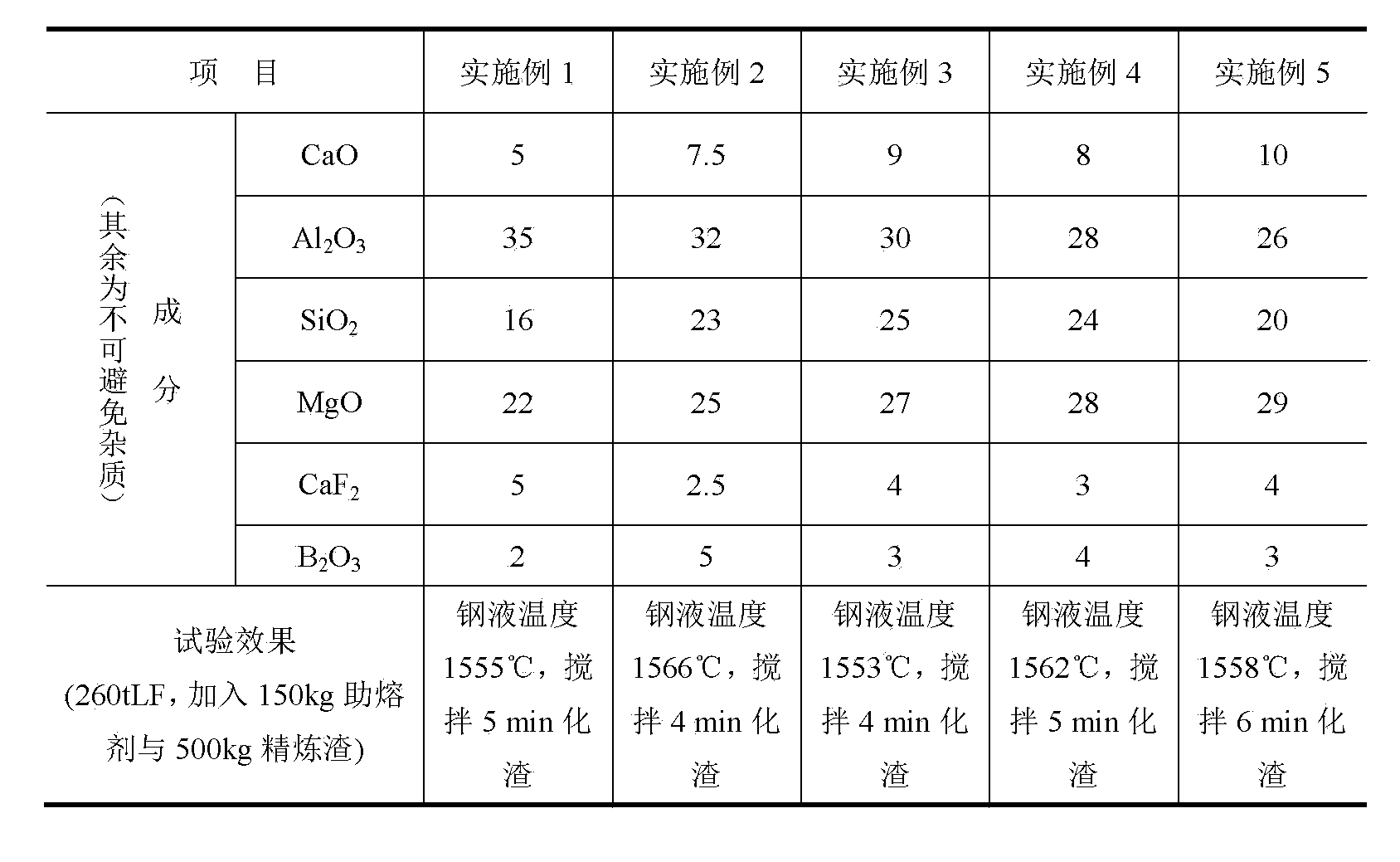

[0016] According to the proportioning of molten steel refining flux of the present invention, quicklime, bauxite, high alumina powder, borax, bentonite, magnesia and fluorite etc. containing CaO, Al 2 o 3 , SiO 2 , MgO, B 2 o 3 , CaF 2 The material powder (100-200 mesh) is mixed evenly according to the weight percentage, then add 5-10% water glass, stir evenly, use a double-roller ball press to press into a spherical material, and then bake and dry at 250-300 °C for 1 ~2h, then cooled to room temperature for 5~6h, after inspection and sieving, the weight of particle size 10~40mm ≥ 95% can be packaged to obtain molten steel refining flux of the present invention. When in use, it is added to the silo, and added to the surface of molten steel slag through the chute. The molten steel refining flux of the present invention uses Al-killed steel such as ship plate and ordinary carbon steel as a carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com