Bromine-containing refining agent for rapid sedimentation of rare earth magnesium alloy, preparation method and application

A rare earth intermediate alloy and rare earth magnesium technology, applied in the field of metal materials and metallurgy, can solve the problems of poor specific gravity of magnesium alloy melt, slow refining agent sedimentation, shortening refining process, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

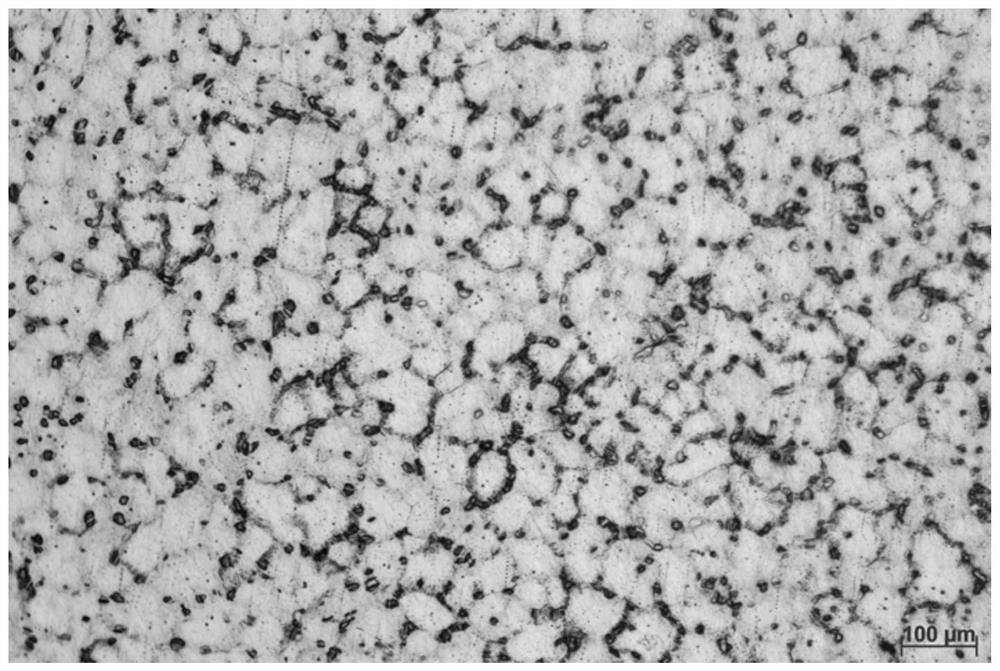

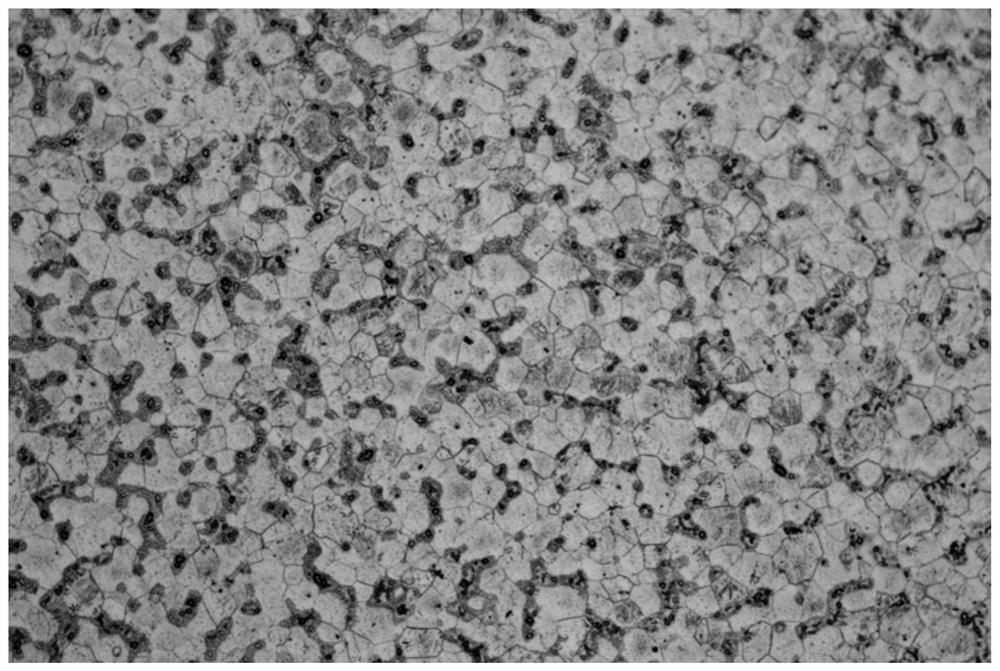

Image

Examples

preparation example Construction

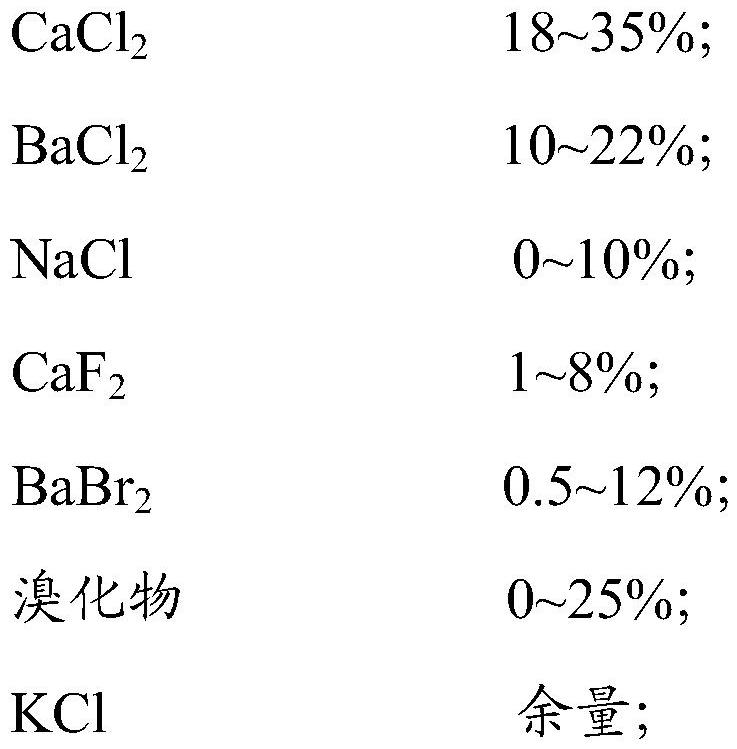

[0044] The above-mentioned preparation method of a bromine-containing refining agent for rapid sedimentation rare earth magnesium alloy comprises the following steps:

[0045] S1, drying and dehydrating the above-mentioned raw materials at 200°C-230°C, and storing them in a dry airtight container for later use; in this step, the dry airtight container can be a drying dish, a sealed bag with moisture-proof function, or sealed in a vacuum bag for pumping. to vacuum.

[0046] S2, heat up the crucible to 250°C and add CaCl mixed uniformly according to the designed ratio 2 , NaCl and KCl, after heating up to partial melting, add BaCl mixed uniformly according to the designed ratio 2 、BaBr 2 and bromide, heat the crucible to 720-790°C, stir for 1-20 minutes after the mixed salt is completely melted, pour it into a mold, solidify and cool it into a block; in this step, the material of the crucible can be graphite crucible, corundum crucible, or It is an iron crucible, as long as i...

Embodiment 1

[0054] A bromine-containing refining agent for rapid settling rare earth magnesium alloys, its components and mass fractions are: KCl: 33%, CaCl 2 : 30%; BaCl 2 : 10%; NaCl: 5%; CaF 2 : 2%; BaBr 2 : 5%; KBr: 10%; CaBr 2 : 5%.

[0055] The preparation method of the bromine-containing refining agent for rapid settling rare earth magnesium alloys of the present invention is as follows: drying and dehydrating the above-mentioned raw materials at 210°C respectively, and storing them in a dry airtight container for later use; heating the crucible to 250°C, adding the Good and well mixed CaCl 2 , NaCl and KCl, after heating up to partial melting, add BaCl mixed uniformly according to the designed ratio 2 、BaBr 2 and KBr, heat the crucible to 750°C, stir for 5 minutes after the flux is completely melted, pour it into a mold, solidify and cool into blocks; break the obtained block flux, and mix with CaF 2 Mix and grind in a ball mill, sieve after grinding, and put into a dry air...

Embodiment 2

[0058] A bromine-containing refining agent for rapid settling rare earth magnesium alloys, its components and mass fractions are: KCl: 36%, CaCl 2 : 25%; BaCl 2 : 13%; NaCl: 0.5%; CaF 2 : 1%; BaBr 2 : 8%; NaBr: 4.5%; CaBr 2 : 12%.

[0059] The preparation method of the bromine-containing refining agent for rapid sedimentation rare earth magnesium alloy of the present invention is as follows: drying and dehydrating the above-mentioned raw materials at 220°C respectively, and storing them in a dry airtight container for later use; heating the crucible to 250°C, adding Good, well mixed CaCl 2 , NaCl and KCl, after heating up to partial melting, add BaCl mixed uniformly according to the designed ratio 2 、BaBr 2 , NaBr and KBr, heat the crucible to 760°C, stir for 10 minutes after the flux is completely melted, pour it into a mold, solidify and cool into blocks; break the block flux, and mix with CaF 2 Mix and grind in a ball mill, sieve after grinding, and put into a dry ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com