Method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag

A technology of calcium-chromium-free slag and ferrochromium powder, applied in the direction of improving process efficiency, can solve the problems of high energy consumption, serious secondary pollution, and low degree of resource utilization, and achieve high recovery rate, low energy consumption, The effect of increasing the degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

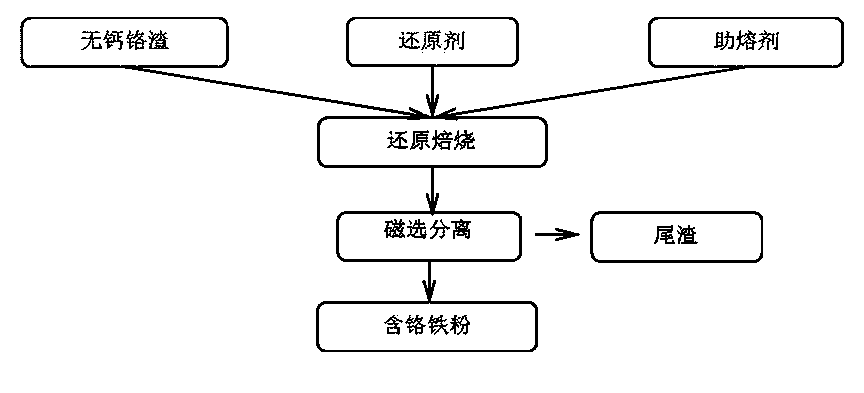

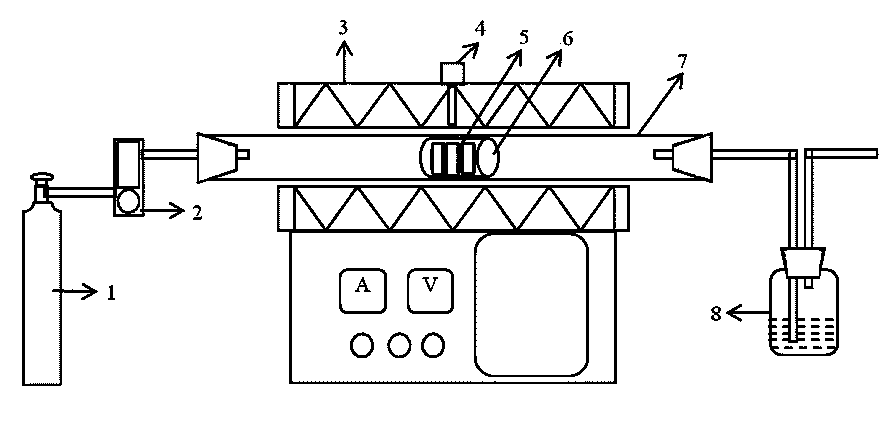

[0032] A method of preparing chromium-containing iron powder through direct reduction of calcium-free chromium slag in this embodiment, its process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0033] (1) Ingredients: mix calcium-chromium-free slag with reducing agent and flux, take 100 g calcium-chromium-free slag in the present embodiment, take 30 g anthracite coal powder as reducing agent, adopt X-ray fluorescence spectrometer and chemical analysis method to the above-mentioned The raw materials were analyzed. The physical and chemical indicators of calcium-free chromium slag and anthracite coal are shown in Table 1 and Table 2. X-ray diffraction analysis of calcium-free chromium slag shows that the minerals mainly include iron chromate, magnetite, forsterite, magnesium-iron Composition of olivine and silicate, from the chemical and phase analysis of calcium-free chromium slag, it can be seen that chromium slag mainly contains three eleme...

Embodiment 2

[0054] A kind of calcium-free chromium slag of the present embodiment prepares the method for chromium-containing iron powder through direct reduction, basically with embodiment 1, and the process parameter of its concrete steps is:

[0055] (1) Ingredients: Mix 100 g of calcium-free chromium slag with reducing agent and flux, wherein the flux is 9 g of alumina and 3 g of calcium fluoride, and the reducing agent is 30 g of anthracite coal powder. The quaternary alkalinity of the mixture is m(MgO+CaO) / m(SiO 2 +Al 2 o 3 )=0.9;

[0056] (2) Agglomeration: press the mixture in step (1) into cakes or pellets to obtain agglomerates;

[0057] (3) Reduction roasting: roast the blocks in step (2) in a reducing atmosphere, the reduction temperature is 1300 °C, and the time is 80 min;

[0058] (4) Crushing and fine grinding: crush the roasted block in step (3) and finely grind it to 80 meshes;

[0059] (5) Magnetic separation: The finely ground powder in step (4) was subjected to ma...

Embodiment 3

[0063] A kind of calcium-free chromium slag of the present embodiment prepares the method for chromium-containing iron powder through direct reduction, basically with embodiment 1, and the process parameter of its concrete steps is:

[0064] (1) Ingredients: Mix 100 g of calcium-free chromium slag with reducing agent and flux, wherein the flux is 1 g of alumina and 3 g of calcium fluoride, the reducing agent is 30 g of anthracite coal powder, and the quaternary alkalinity of the mixture is m(MgO+CaO) / m(SiO 2 +Al 2 o 3 )=1.3;

[0065] (2) Agglomeration: press the mixture in step (1) into cakes or pellets to obtain agglomerates;

[0066] (3) Reduction roasting: roast the blocks in step (2) in a reducing atmosphere, the reduction temperature is 1300 °C, and the time is 50 min;

[0067] (4) Crushing and fine grinding: crush the roasted block in step (3) and finely grind it to 120 mesh;

[0068] (5) Magnetic separation: The finely ground powder in step (4) was subjected to mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com