Thick steel sheet and production method therefor

A manufacturing method and thick steel plate technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of no longer maintaining the safety of structures for extremely low temperature storage tanks, poor low temperature toughness, etc., achieve excellent deformation characteristics, improve safety effect

Pending Publication Date: 2021-11-09

JFE STEEL CORP

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the low-temperature toughness of steel is poor, there is a possibility that the safety as a structure for cryogenic storage tanks will no longer be maintained

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

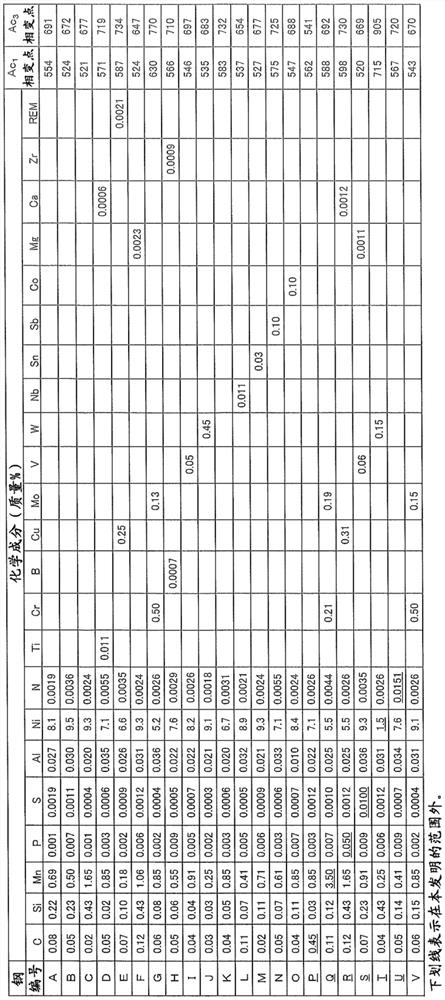

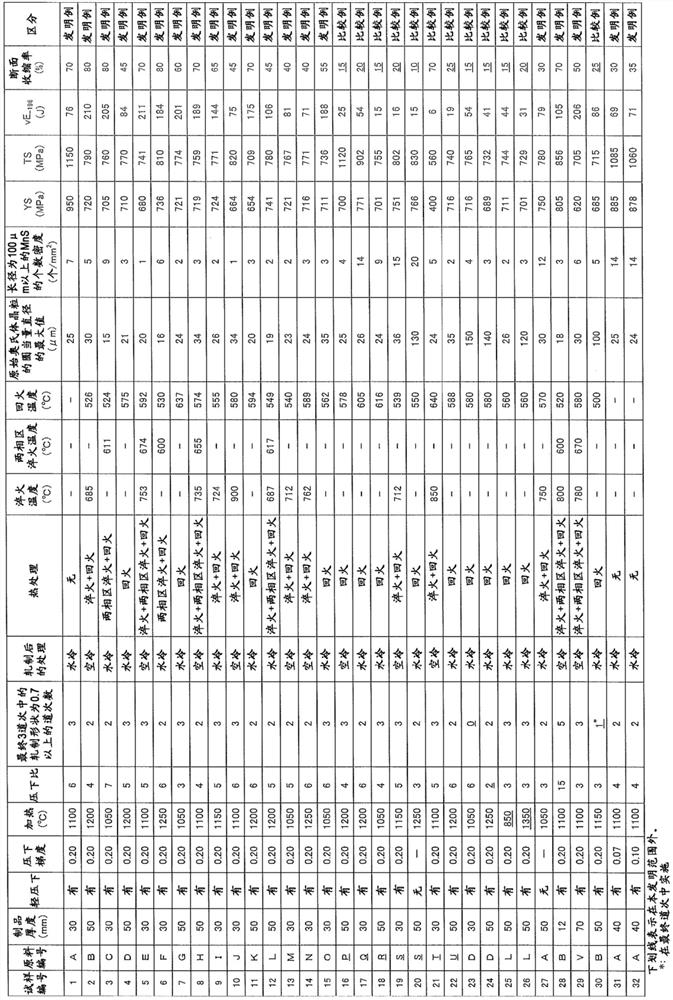

[0109] Steel with the composition shown in Table 1 was melted to form a slab, and then thick steel plates with a plate thickness of 12 to 70 mm were produced according to the production conditions shown in Table 2. It should be noted that in light reduction, the reduction gradient was set to 0.20 mm / m for samples No. 1 to 30, and 0.07 mm / m and 0.10 mm / m for samples No. 31 and 32, respectively. mm / m.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Login to View More

Abstract

The purpose of the present invention is to provide a thick steel sheet having excellent deformation characteristics at a center portion in the thickness direction thereof; and a production method therefor. This thick steel sheet is characterized by having a component composition containing, in mass%, 0.01-0.15% of C, 0.01-1.00% of Si, 0.10-2.00% of Mn, 0.010% or less of P, 0.0050% or less of S, 0.002-0.100% of Al, 5.0-10.0% of Ni, and 0.0010-0.0080% of N, the balance being Fe and incidental impurities, and having a tensile reduction of area of 30% or more in the thickness direction thereof at a center portion thereof in the thickness direction.

Description

technical field [0001] The present invention relates to a thick steel plate of structural steel suitable for use in extremely low temperature environments such as tanks for liquefied gas storage tanks and a method for manufacturing the same. In particular, it relates to a thick steel plate excellent in mechanical properties, especially deformation properties, at the central portion of the plate thickness, and a method of manufacturing the same. In addition, the thick steel plate in this invention refers to the steel plate whose plate thickness is 6-80 mm. Background technique [0002] For thick steel plates used in extremely low temperature environments such as tanks for liquefied gas storage tanks, not only the strength of the steel plate but also the toughness at extremely low temperatures are required. For example, when a thick steel plate is used for a storage tank of liquefied natural gas (LNG), it is necessary to secure excellent toughness below the boiling point of L...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/02C22C38/00C22C38/08C22C38/60

CPCC22C38/08C22C38/60C22C38/02C22C38/04C22C38/001C22C38/14C22C38/18C22C38/002C22C38/16C22C38/008C22C38/005C21D8/0226C21D6/001C21D8/021C21D8/0263C21D1/185C21D1/25C21D1/18C21D9/46C21D1/02C22C38/06C22C38/58C22C38/44C22C38/48C22C38/46C22C38/50C22C38/42C22C38/54B21B3/02C21D6/002C21D6/005C21D6/007C21D6/008C21D8/0205C22C38/10C22C38/22

Inventor 佐藤祐也木津谷茂树太田周作横田智之

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com