Fastener Clip with Seal

a technology of fastener and seal, which is applied in the direction of snap fasteners, buckles, mechanical devices, etc., can solve the problems of missing pieces, panel attached to a doorframe without the desired sealing against the doorframe, and wrong fasteners being inadvertently inserted into a portion of the doorfram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

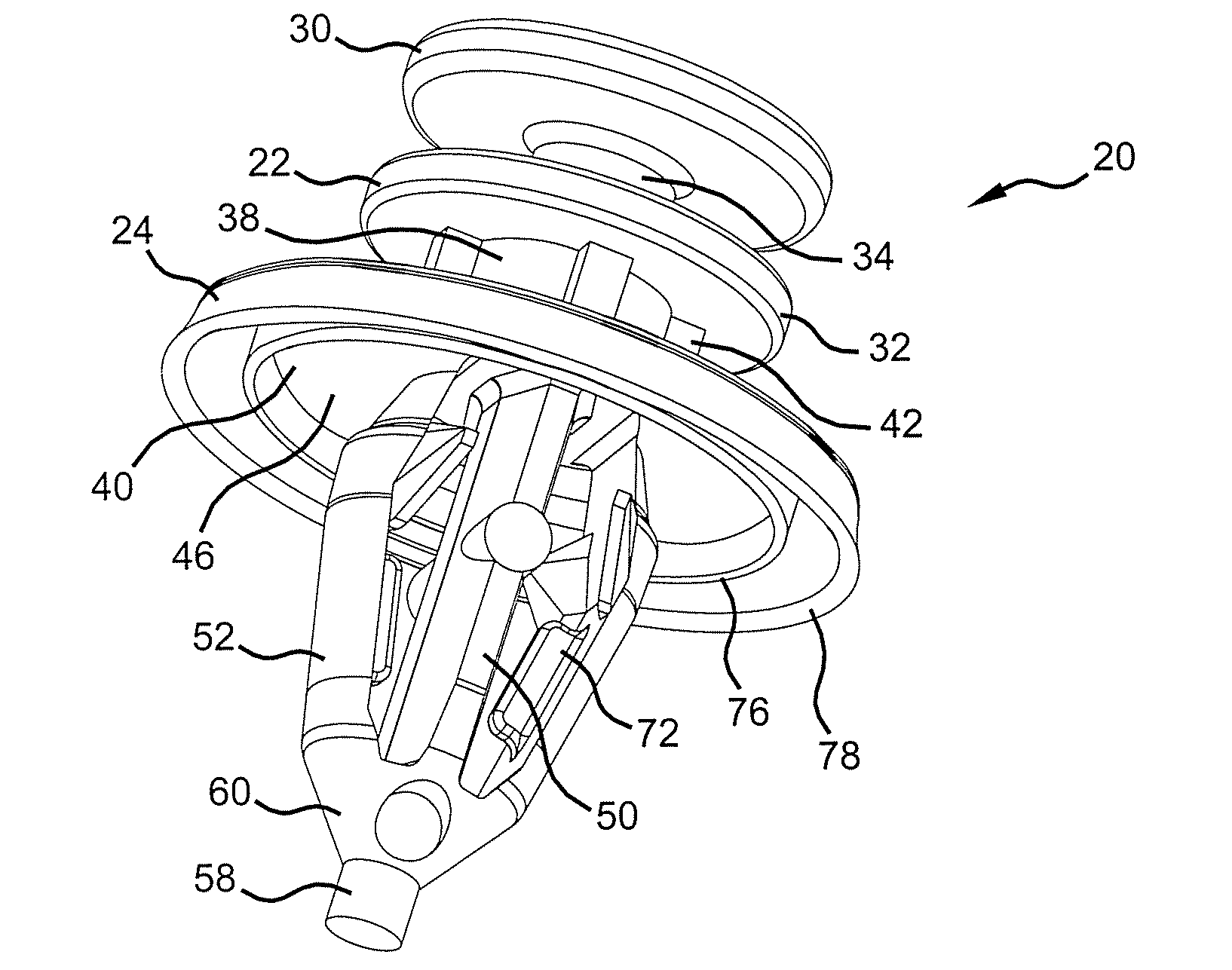

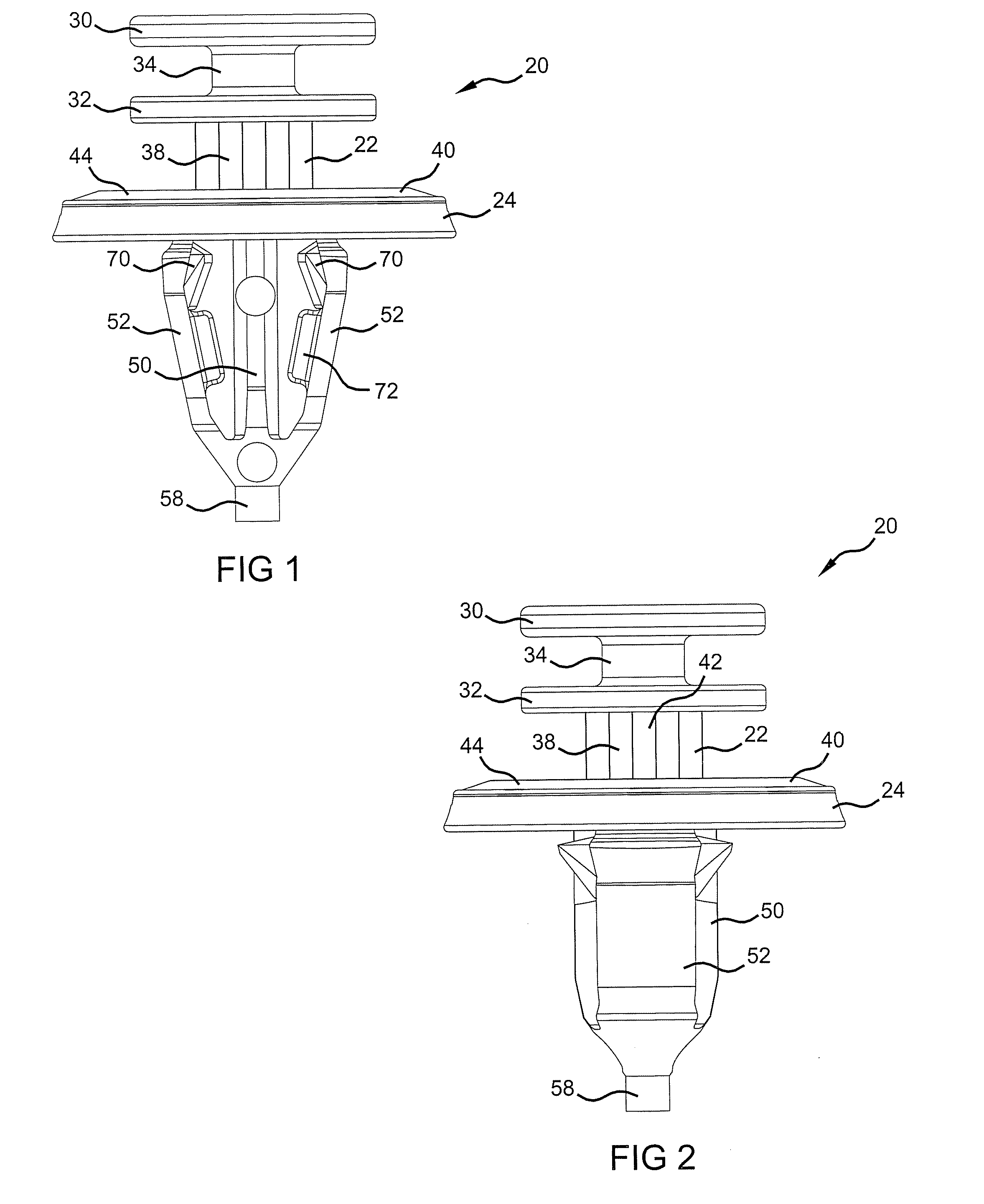

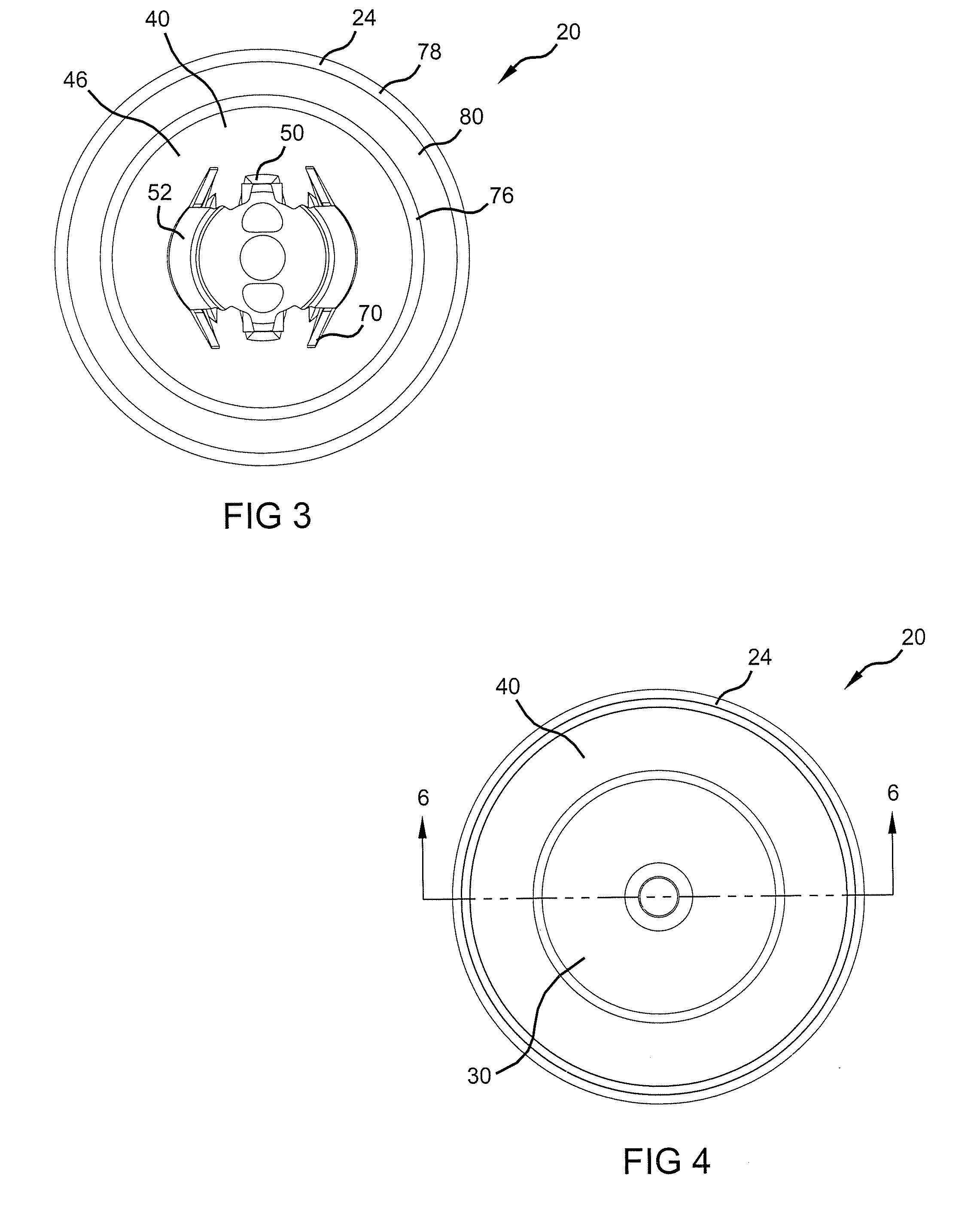

[0053]The following description is merely exemplary in nature and is not intended to limit the present teachings, application, or uses. It should be understood that throughout the drawings, corresponding reference numerals (e.g., 20, 20′, 20″, etc. and 20, 120, 220, etc.) indicate like or corresponding parts and features.

[0054]Referring to FIGS. 1-8, a single-piece fastener 20 according to the present teachings is shown. Fastener 20 includes a clip 22 and a seal 24 attached thereto. Clip 22 is a relatively hard and rigid piece while seal 24 is a relatively soft and flexible piece. Fastener 20 is operable to retain a panel, such as a door panel 26, to a frame or support member, such as doorframe 28, as shown in FIG. 8. Seal 24 is operable to seal against doorframe 28 to inhibit moisture, liquids, debris, and noise from entering into the interior of the automotive vehicle through doorframe 28.

[0055]Clip 22 includes a generally-circular head 30 and a generally-circular collar 32 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| areas | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com