New method for welding plastics by metal laser welding machine

A technology of a laser welding machine and a new method, applied in the field of laser welding, can solve the problems of large vibration stress and thermal stress, shortened service life, fast aging speed, etc., and achieves small vibration stress and thermal stress, easy control, and less resin degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment.

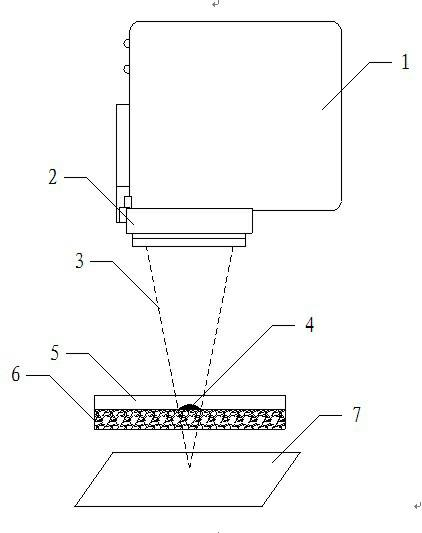

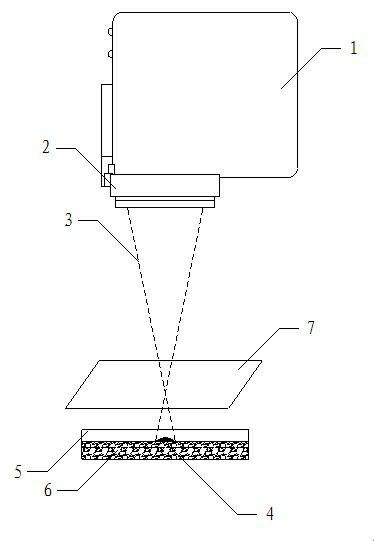

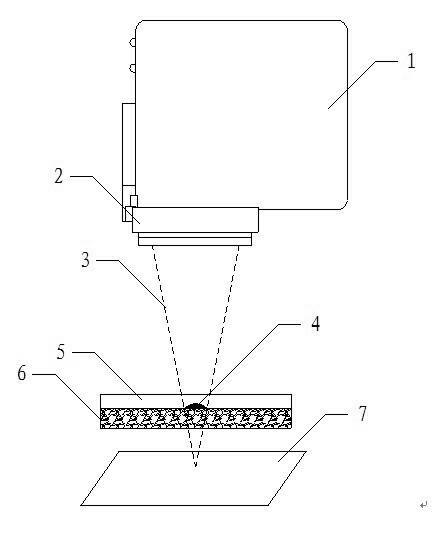

[0019] A new method of welding plastics using a metal laser welding machine that can create welds that exceed the strength of the raw material, the steps are as follows:

[0020] a) Select semiconductor laser welding machine, fiber laser welding machine or end-pump laser welding machine, use computer-controlled special board to output near-infrared laser with a certain frequency and wavelength of 800-1064nm;

[0021] b) Clamp the two plastic parts to be welded together, let the near-infrared laser transmit through the first part in a way that deviates from the focus, where the distance from the focus is 50-90mm, and the diameter of the spot is 3-5mm. Absorbed by the second component, the absorbed near-infrared ray is lasered into heat energy, melting the contact surfaces of the two components to form a welding zone. The welding process parameters are as follows: the current is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com