Lycopene microcapsule prepared by adopting a double-coating method and preparation method thereof

A technology of lycopene and lycopene oil, which is applied in the field of preparation of lycopene microcapsules and lycopene extraction and preparation, can solve the problems of lycopene destruction, instability, oxidative decomposition, etc., to promote uniform concentration and improve dispersion Sexuality and solubility, and the effect of improving biological potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one: the preparation of lycopene microcapsules

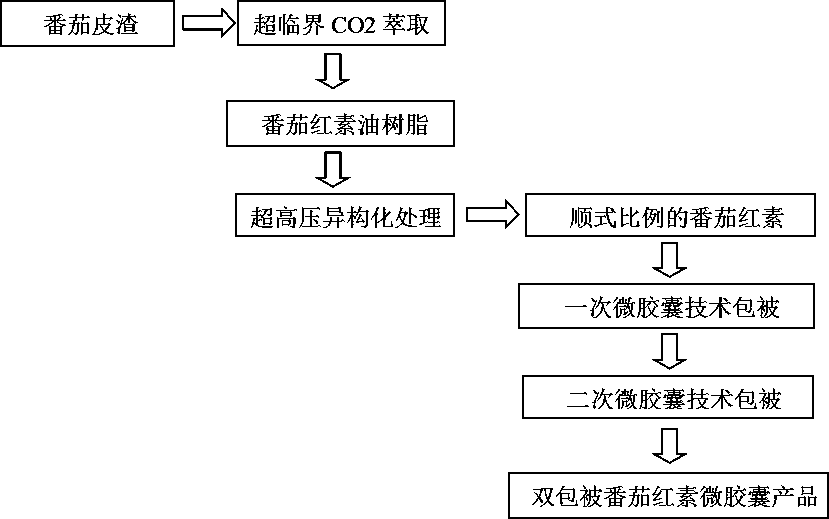

[0055] Refer to attached figure 1 , adopt double-coating method to prepare the method for lycopene microcapsules, concrete steps are as follows:

[0056] (1) Preparation of tomato peels: Select non-mildew tomato peels, remove sundries, and wash the soil and sundries on the peels with clean water for later use.

[0057] (2) Preparation of lycopene oleoresin: the above prepared tomato pomace was treated with supercritical CO 2 Extraction, pressure 28MPa, extraction temperature 70-72.5°C, CO? flow rate 2500-2600kg / h, extraction time: 120min, under this process condition, lycopene with a purity of over 90% can be obtained; Medium supercritical CO 2 The extracted 6% lycopene oleoresin is used as a raw material, which ensures that the raw material does not contain any chemical components and solvent residues, and is safe and non-toxic.

[0058] (3) Lycopene purification process: Dissolve the lycopene oleoresin pr...

Embodiment 2

[0064] Example 2: Preparation of cis-lycopene by ultra-high pressure

[0065] The lycopene sample was dissolved in n-hexane with a concentration of 50 μg / mL, and packed into a polyethylene composite bag and vacuum-sealed. Ultrahigh pressure treatment was carried out under different pressure, time and temperature to investigate the degree of internal isomerization of lycopene and the content of lycopene.

[0066] Effect of different ultra-high pressure treatment conditions on lycopene isomerization: Through ultra-high pressure treatment under different pressure, time and temperature, the degree of internal isomerization of lycopene and the content of lycopene were investigated. The results are shown in Table 1.

[0067] Table 1: Effects of different treatment conditions on isomerization of lycopene

[0068] sample Proportion of cis-lycopene (%) Lycopene content (mg / g) untreated sample 13.25% 52.37mg / g 400Mpa, 10min, 50℃ 34.76% 87.94mg / g 5...

Embodiment 3

[0079] Embodiment three: Lycopene microcapsules one-time coating process test

[0080] The choice of primary coating lycopene wall material, wall material component ratio, core-wall ratio, emulsifier dosage and solid content were determined by single factor experiment, and the primary coated lycopene microcapsules were emulsified by ultrasonic assisted emulsification method The liquid is emulsified and dried by spray drying. Since ultrasonic-assisted emulsification and spray drying involve a variety of parameters, the uniform design experiment method was selected to screen and analyze the significance of each parameter, and finally the two most significant factors were determined to be positive together with the two most significant factors in the single factor. Submit experimental optimization to obtain the optimal process and formula.

[0081] Conclusion: The optimal process for the preparation of lycopene microcapsules by ultrasonic-assisted emulsification and spray dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com